Submerged arc furnace copper pressure ring and processing method thereof

A technology for pressure rings and submerged arc furnaces, which is applied in the direction of electric heating devices, heating through discharge, electrical components, etc., and can solve problems affecting the service life of copper pressure rings, heating shutdown for maintenance, damage and leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

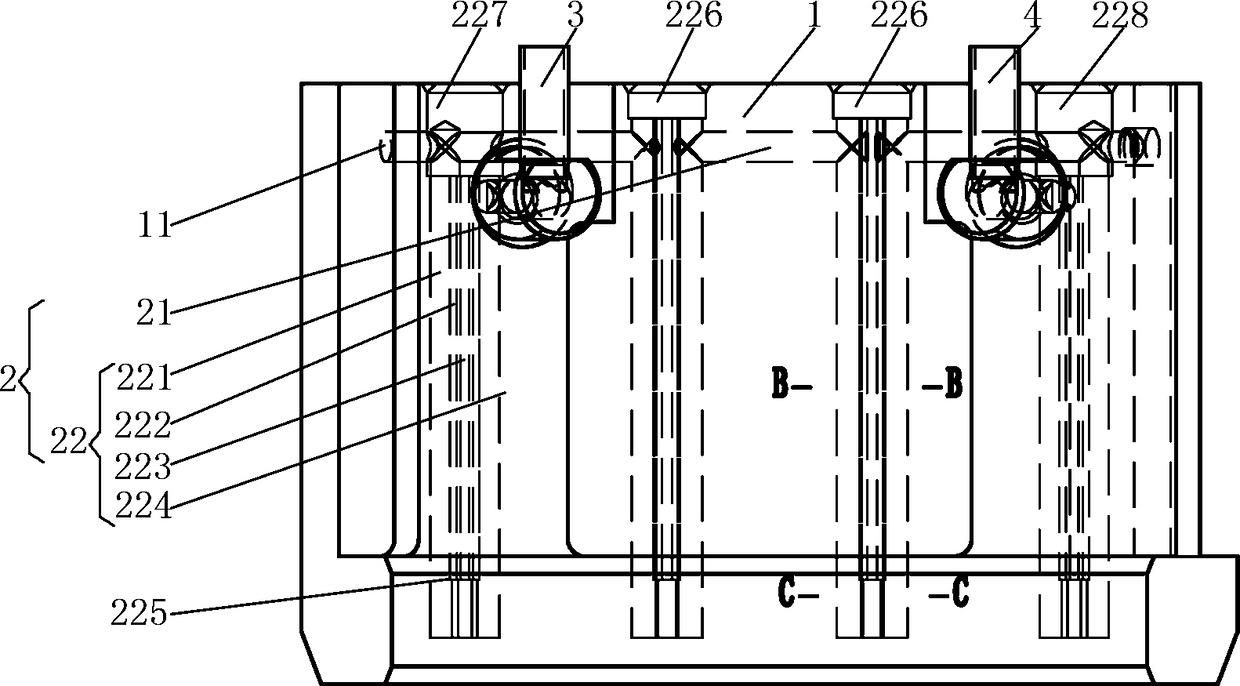

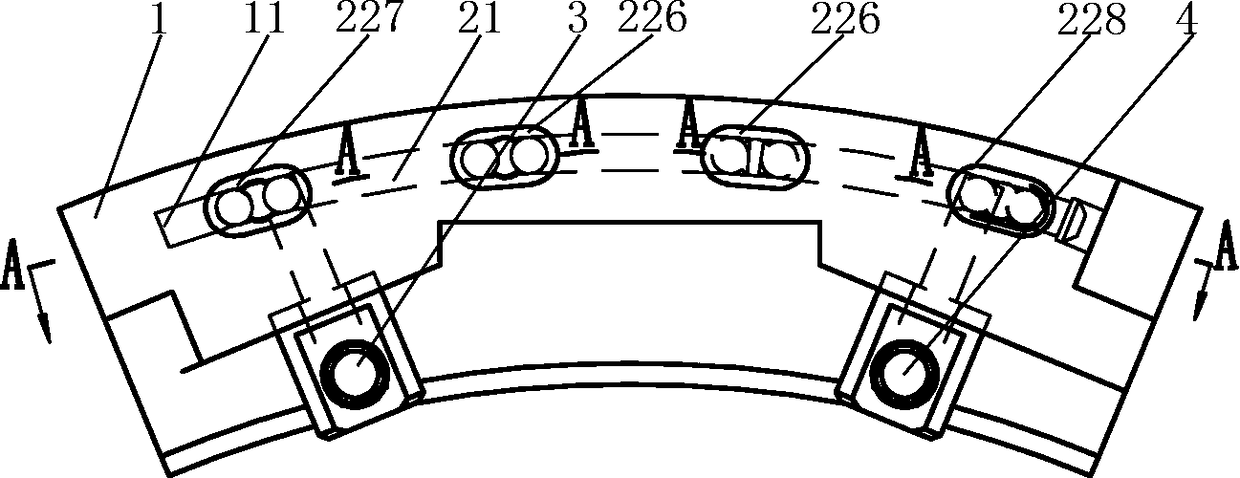

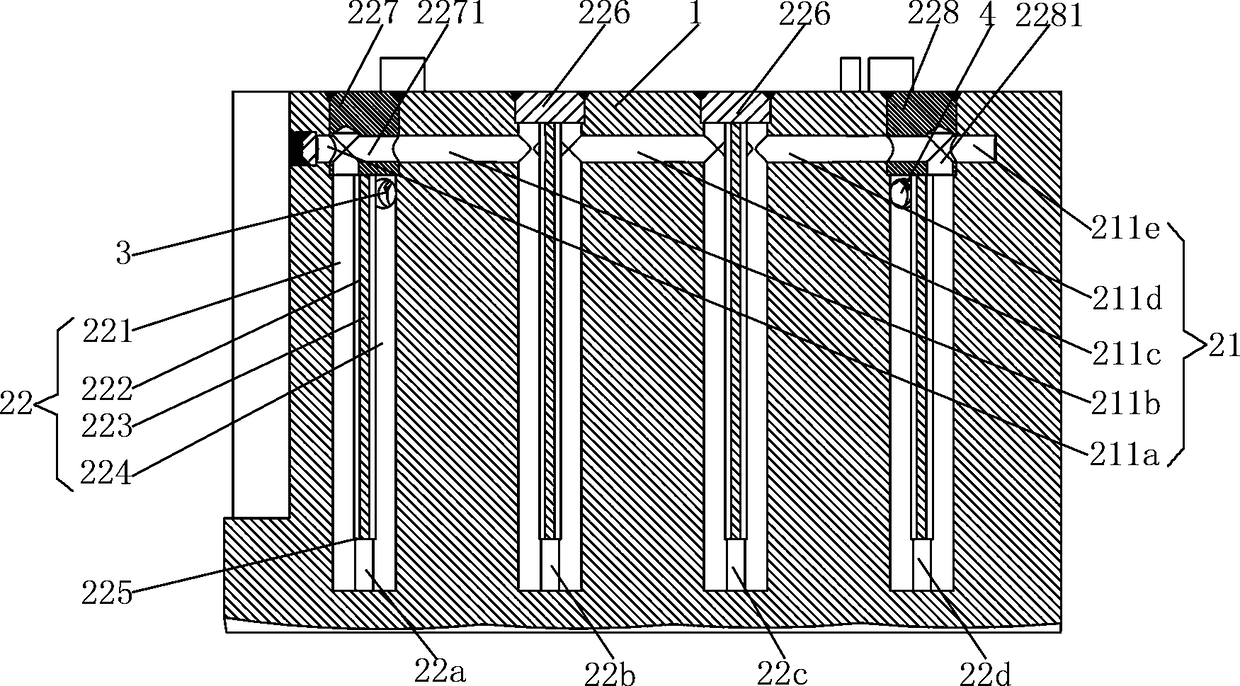

[0045] Such as Figure 1-7 As shown, a copper pressure ring of a submerged arc furnace in this embodiment includes a plurality of copper pressure ring units, and the copper pressure ring unit includes a copper pressure ring unit body 1, and a cooling channel 2 is arranged in the copper pressure ring unit body 1, Two ends of the cooling channel 2 are respectively provided with a water inlet 3 and a water outlet 4. The cooling channel 2 includes a transverse channel section 21 and four U-shaped channel sections 22. The transverse channel section 21 is located on the top of the copper pressure ring unit body 1. Each U The U-shaped channel section 22 is arranged in order from left to right on the copper pressure ring unit body 1; the U-shaped channel section 22 includes a left flow channel 221, a middle flow channel 222, a middle plug 223 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com