Electrical Contact Method and Structure of Rotating Capacitor Rotor in Synchrocyclotron

A cyclotron and rotating capacitor technology, applied in magnetic resonance accelerators, electrical components, accelerators, etc., can solve the problems of low rotational speed of rotating capacitors, cumbersome electrical contact structure, complicated cavity structure design, etc., and achieve good vacuum sealing and guarantee. Electrical contact stability, lower water cooling requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

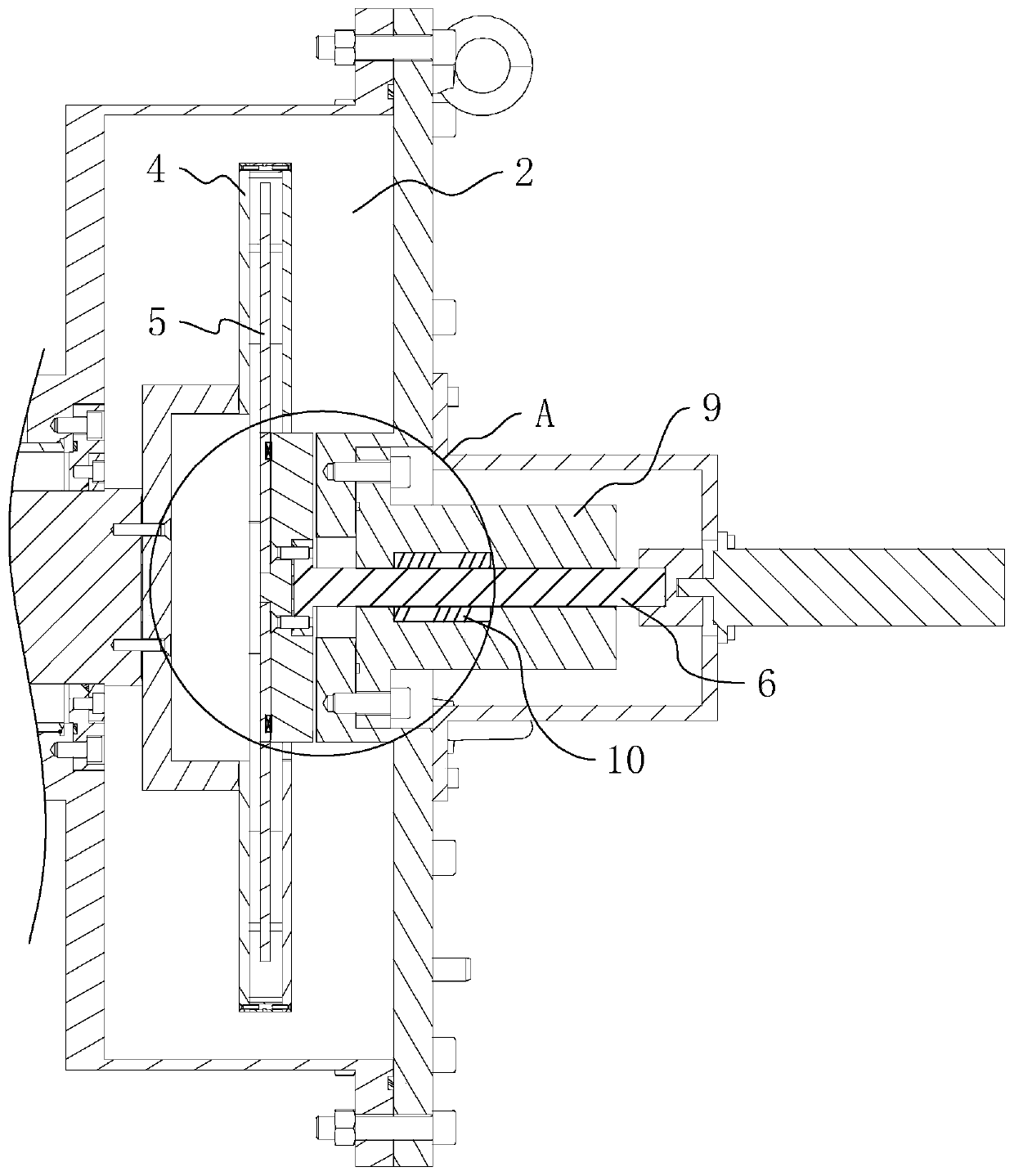

[0035] Embodiments, taking a medical synchrocyclotron as an example, introduce the specific structure of the electrical contact structure of the rotating capacitor rotor in the synchrocyclotron, the electrical contact structure of the rotating capacitor rotor is applied to the electrical contact of the rotating capacitor rotor in the synchrocyclotron in the present invention method.

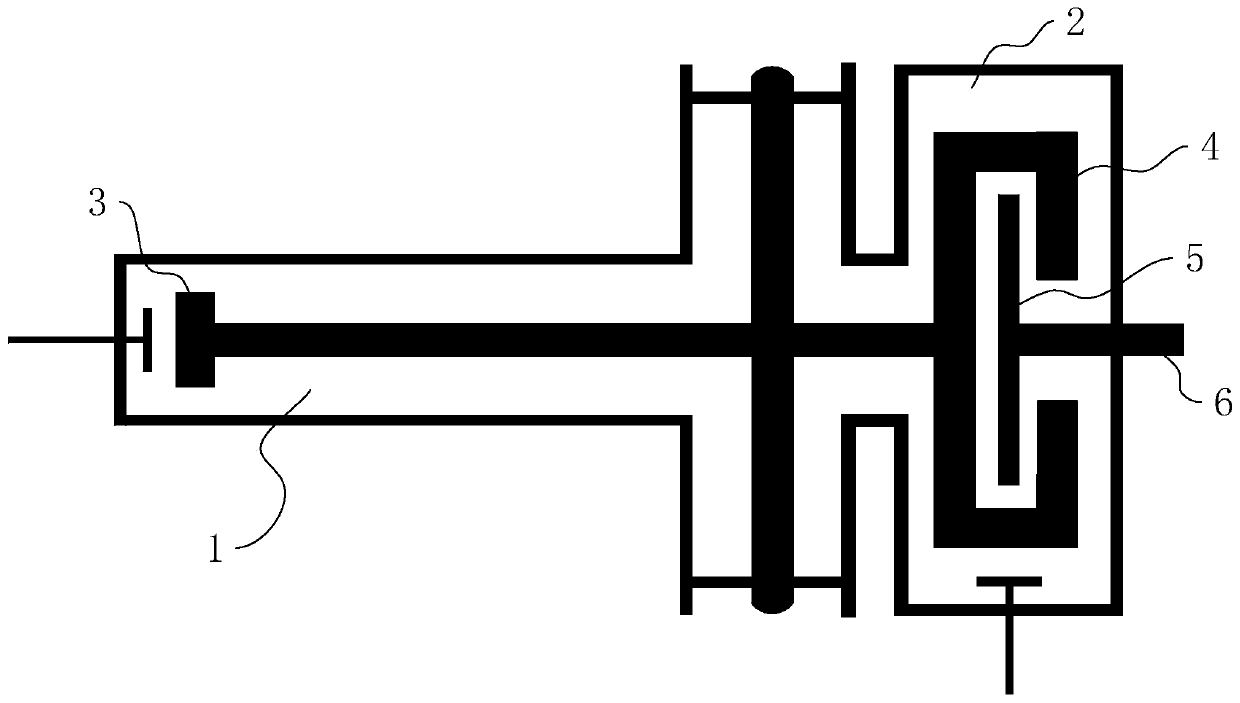

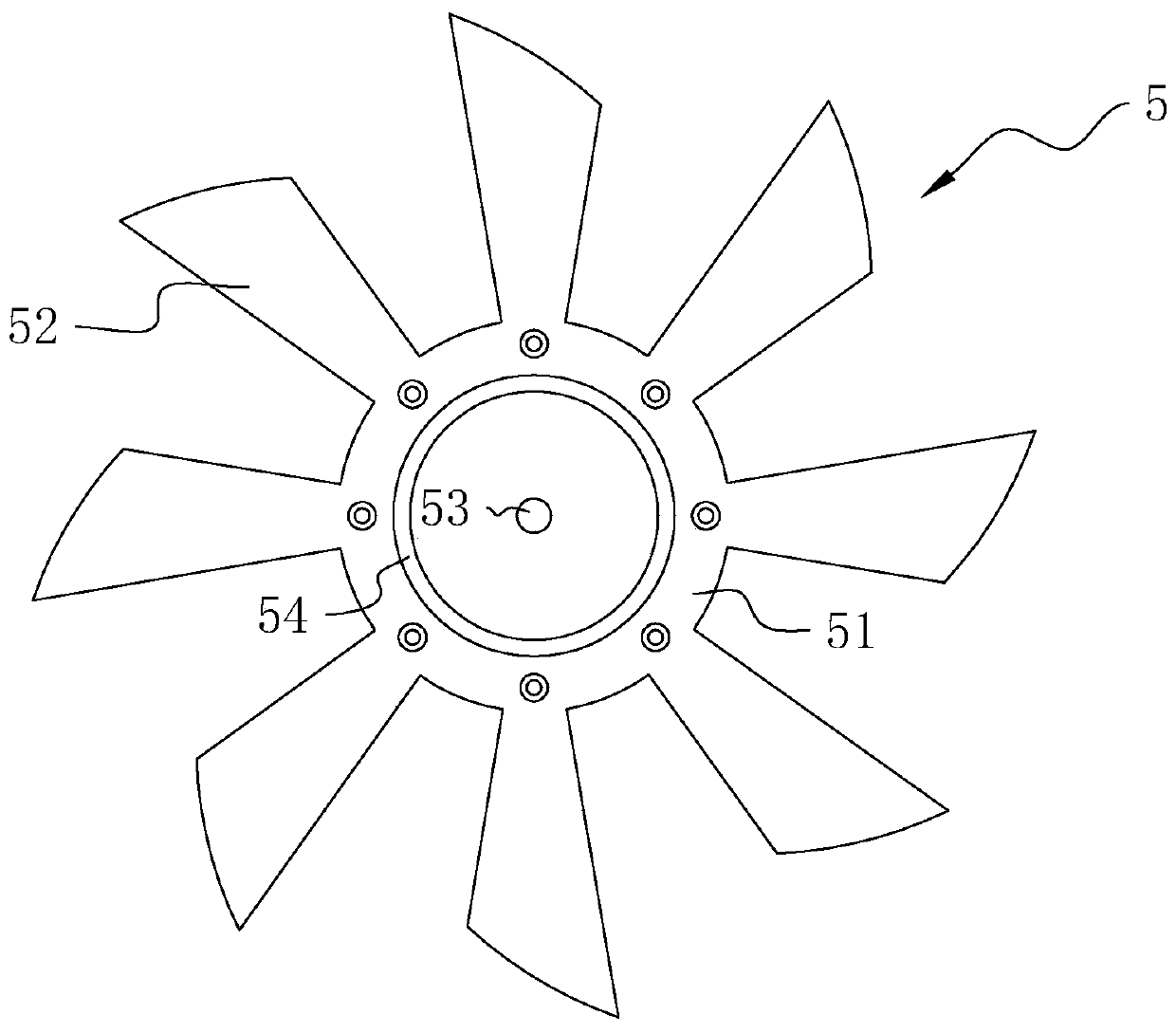

[0036] The synchrocyclotron adopts a variable capacitance method to obtain a frequency of 60MHz-85MHz, and the design value of the modulation frequency is 1kHz. Among them, the ion acceleration time is 0.328ms. figure 1 It is a schematic diagram of the cavity structure of a synchrocyclotron, which adopts a half-wavelength structure; it includes a main vacuum chamber 1 arranged at the head and a capacitor vacuum chamber 2 arranged at the tail. The main vacuum chamber 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com