Fireproof dedusting cutting device for wood processing

A technology of cutting device and dust removal device, which is applied in the direction of wood processing equipment, manufacturing tools, sawing equipment, etc., can solve the problems that the working environment of wood cutting can not be improved to the maximum effect, the cooling of cutting saws, and the dust collection effect are poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

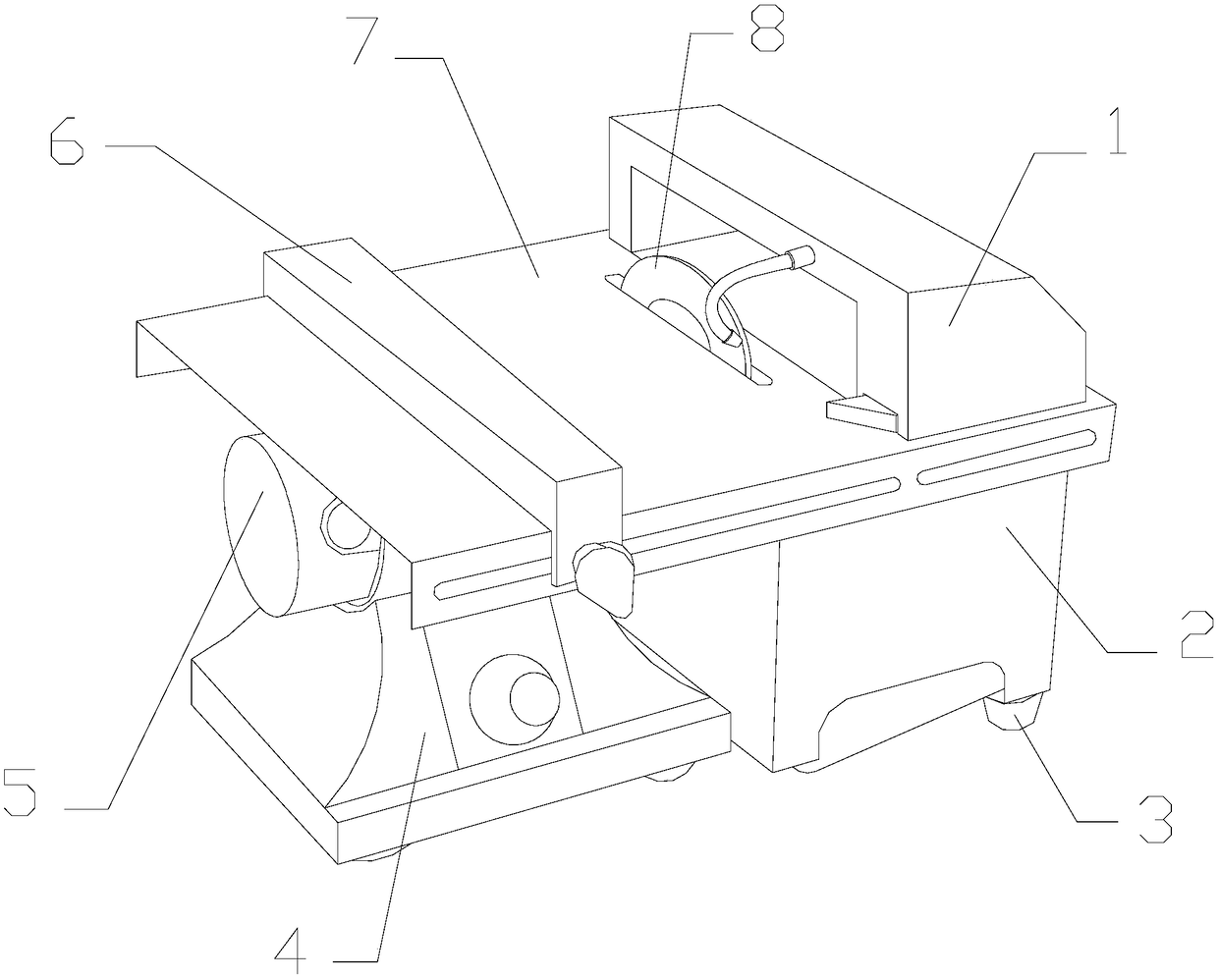

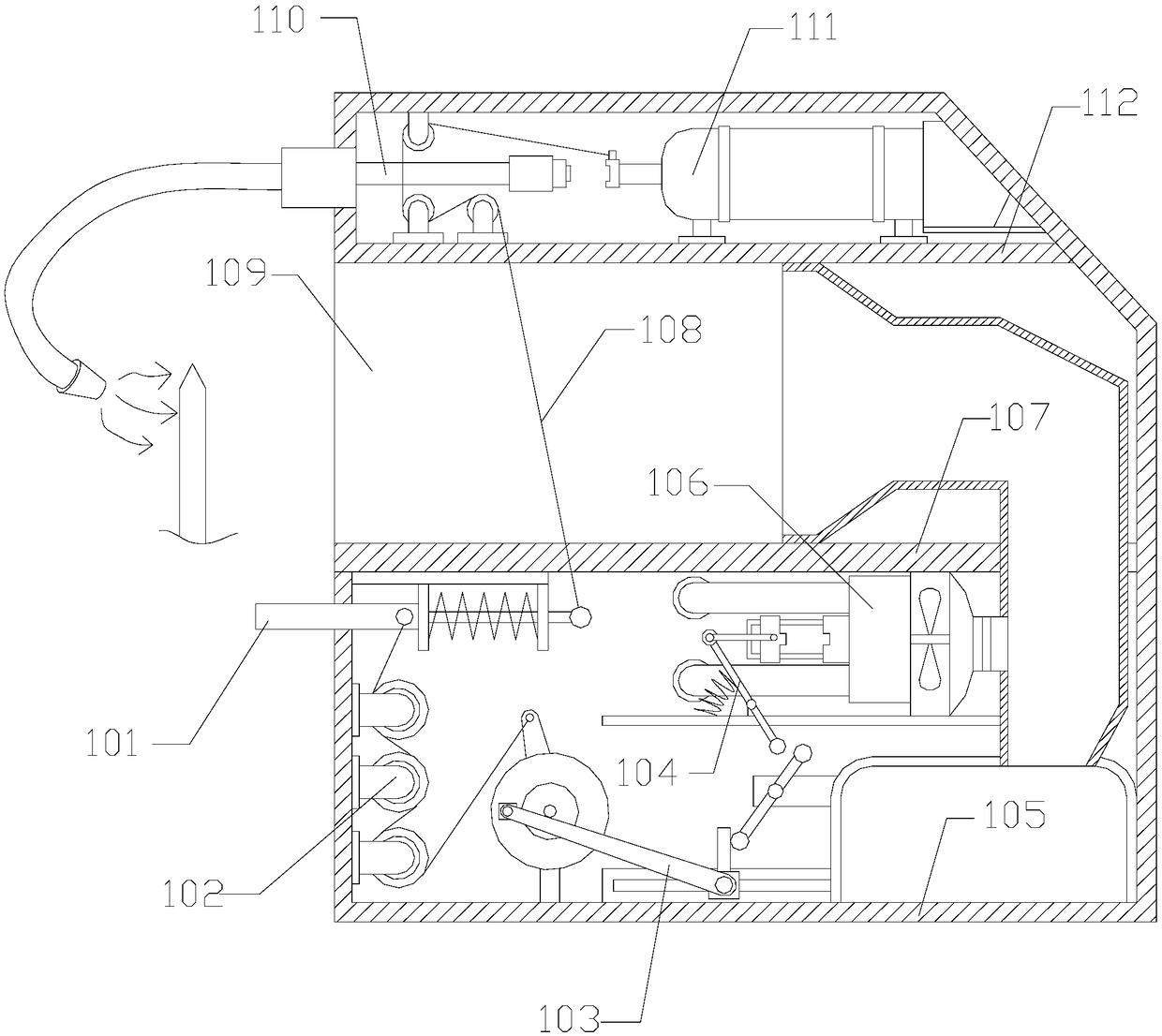

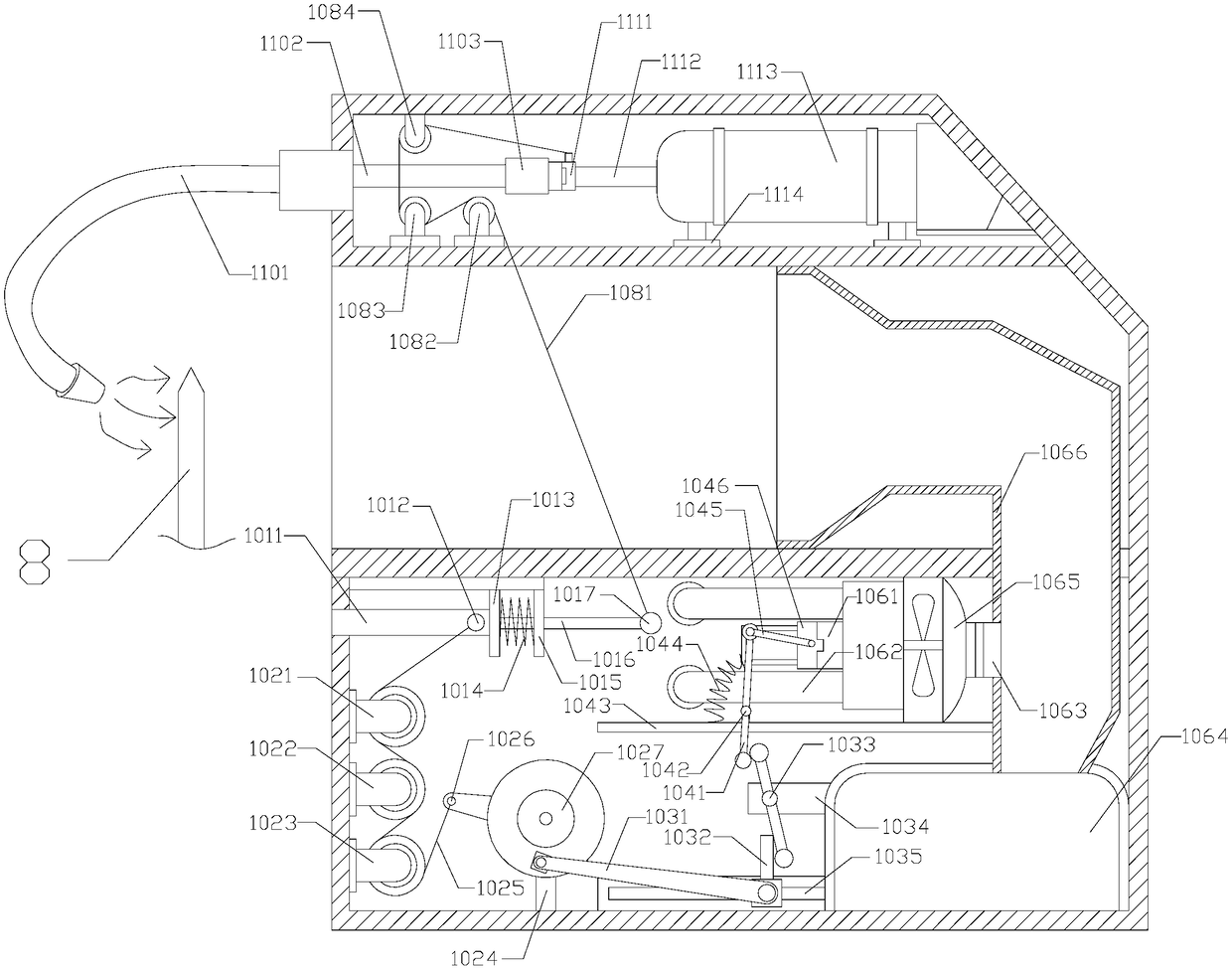

[0026] see Figure 1-Figure 5 , the present invention provides a cutting device for wood processing capable of fire prevention and dust removal: its structure includes a dust removal device 1, a processing host 2, an anti-skid foot 3, an auxiliary base 4, a main motor 5, a positioning frame 6, a processing table 7, a cutting saw 8, the anti-slip feet 3 are provided with more than two and are evenly and equidistantly installed on the bottom of the processing host 2, the top of the processing host 2 is engaged with the right end of the bottom of the processing table 7, and the bottom of the processing table 7 is The left end is provided with an auxiliary base 4, and the upper end of the auxiliary base 4 is provided with a groove for movable installation of the main motor 5, and the first and last ends of the positioning frame 6 are mounted on the left end of the processing table 7 by buckling, and the processing Two-thirds of the middle part of the right end of the table top 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com