Graphene roll stripping system

A graphene and rolling technology, applied in the field of graphene rolling peeling systems, can solve the problems of inability to grind graphene, low shearing efficiency, difficult shearing peeling, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

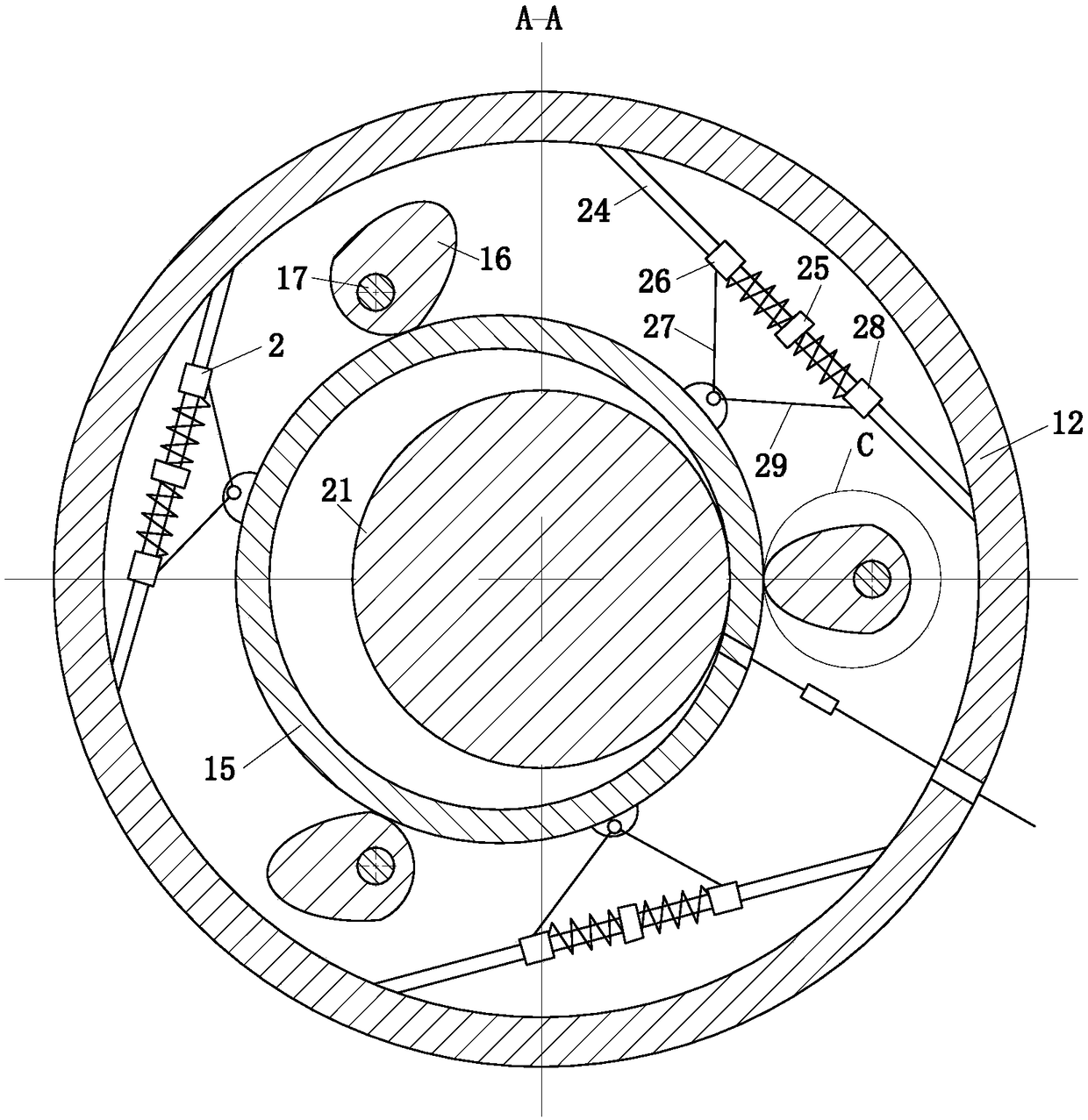

[0026] As an embodiment of the present invention, the No. 1 limit mechanism 2 includes a sliding rod 24, a fixed block 25, a No. 1 sliding block 26, a No. 1 connecting rod 27, a No. 2 sliding block 28 and a No. 2 connecting rod 29, The middle position of described slide bar 24 is fixedly installed with fixed block 25, and slide bar 24 is slidably installed No. 1 sliding block 26 and No. 2 sliding block 28; One side of described fixed block 25 is connected with No. 1 sliding block 26 by spring , the other side of the fixed block 25 is connected with the No. 2 sliding block 28 by a spring; the No. 1 sliding block 26 is hinged with the mounting block through the No. 1 connecting rod 27, and the No. 2 sliding block 28 is connected with the mounting block through the No. 2 connecting rod 29 Hinged; three sets of No. 1 limit mechanism 2 are used to limit the extrusion cylinder 15 to prevent the extrusion cylinder 15 from disengaging from the three cam groups 16; if the extrusion cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com