Substrate frame conveying device in vacuum chamber of vacuum coating machine

A technology of a vacuum coating machine and a conveying device is applied in the directions of vacuum evaporation coating, sputtering coating, ion implantation coating, etc. The effect of shortening the length and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments of the specification, but the protection scope of the present invention is not limited to the following specific embodiments.

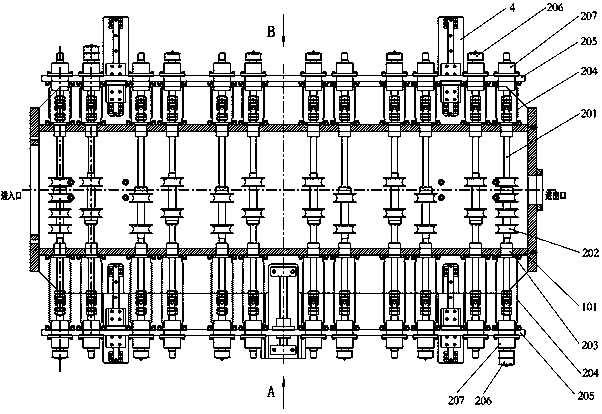

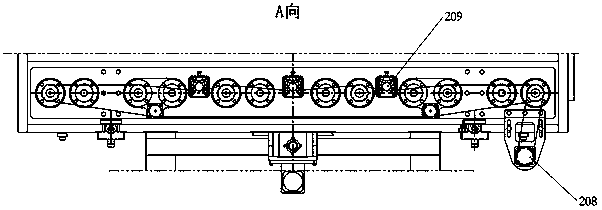

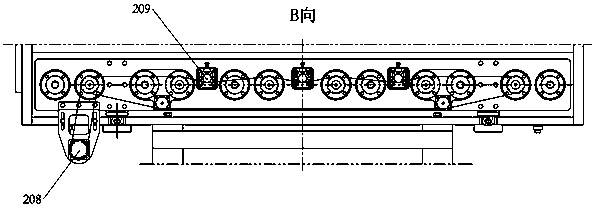

[0016] Such as figure 1 — Figure 5 As shown, the substrate rack conveying device in the vacuum chamber of the vacuum coating machine in this embodiment includes a transmission mechanism and a translation mechanism. The transmission mechanism includes a plurality of transmission rods 201 passing through the side plates 101 on both sides of the vacuum chamber. The transmission rods 201 and the vacuum chamber side plates 101 are connected by linear bearings 203. The two ends of the transmission rods 201 are respectively installed in two installations. On the plate 205, the transmission rod 201 and the mounting plate 205 are connected by a magnetic fluid sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com