Electrochemical deposition support for preparing nano material

A nanomaterial, electrochemical technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of long-term effective use of the device, electrolyte acid penetration, poor sealing performance, etc. Long-term effective use, increase effective use area, and prevent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

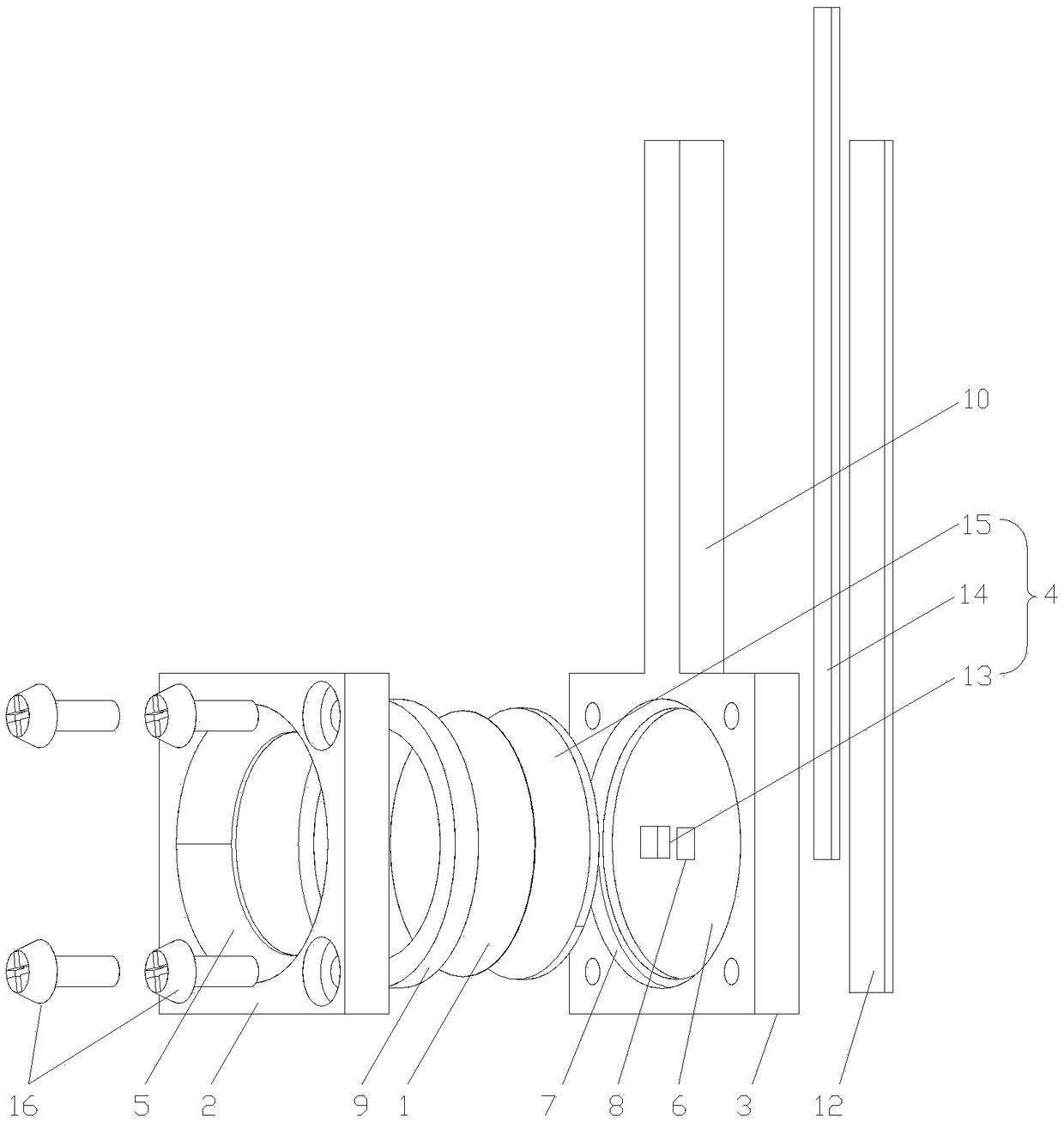

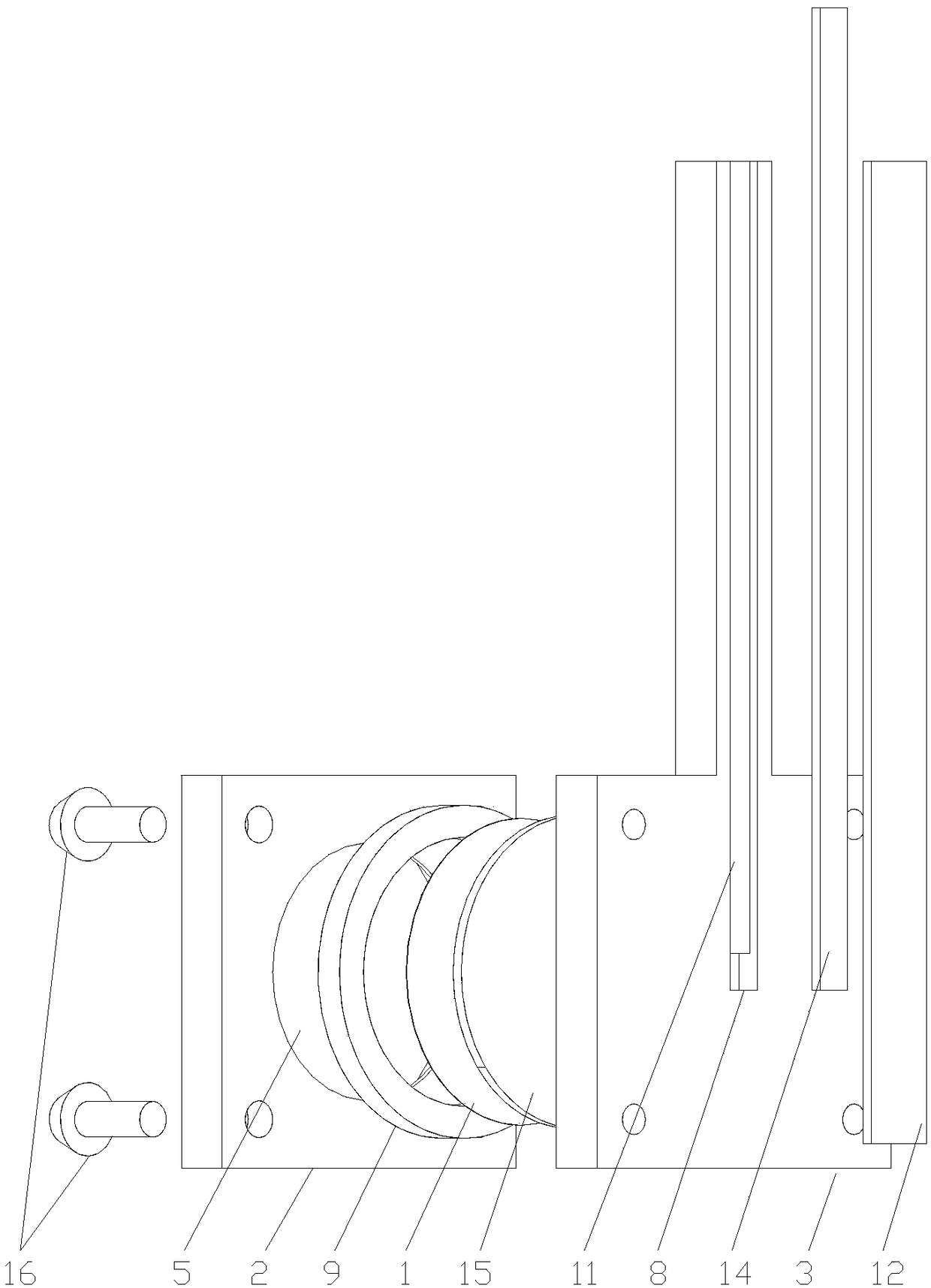

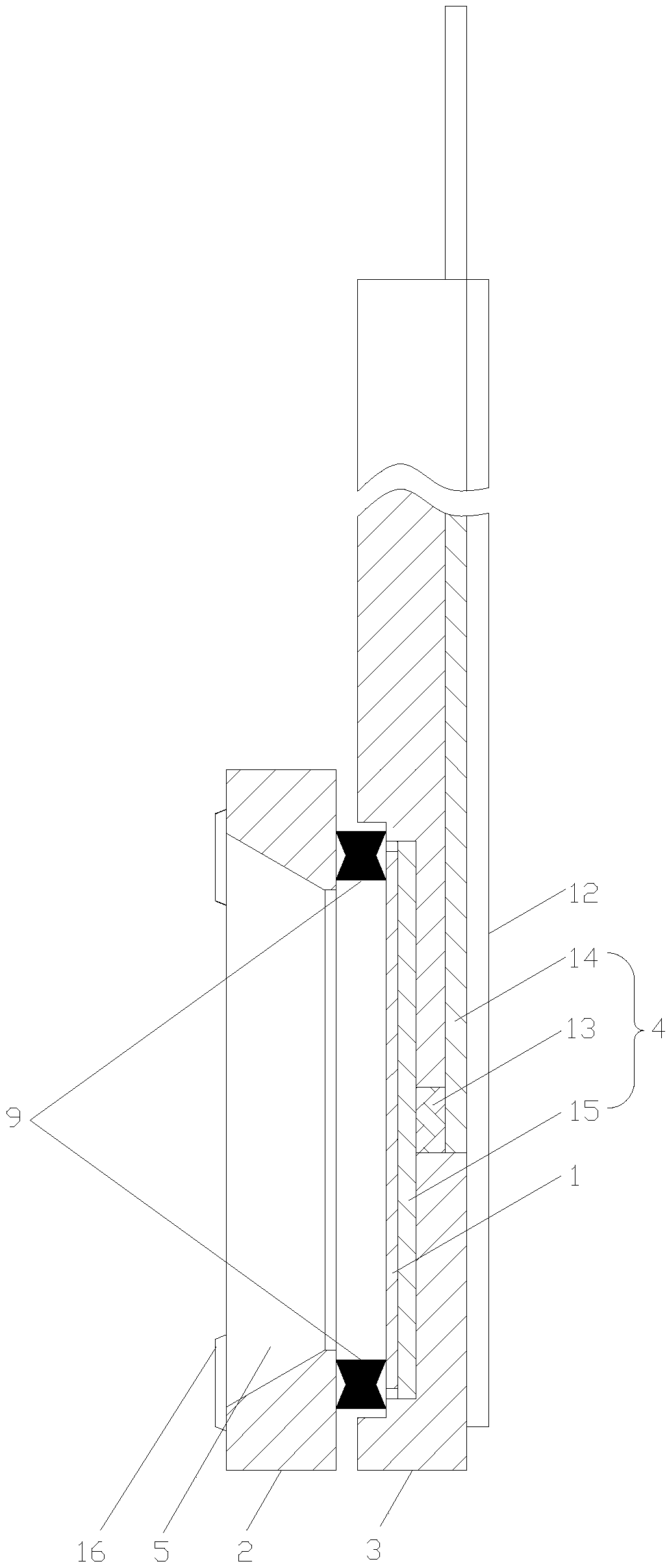

[0027] Embodiment 1 of the present invention: a kind of electrochemical deposition support for preparing nanomaterials, such as Figure 1-Figure 3 As shown, it includes a base 1, a front cover 2, a bracket base 3 and a conductive component 4, the base 1 is fixed through the front cover 2 and the bracket base 3, the conductive component 4 is arranged on the bracket base 3, and the base 1 is connected to the conductive component 4, and a through hole A5 is opened through the front cover plate 2, and the end of the through hole A5 away from the bracket base 3 is provided with a chamfer, and the chamfer makes the through hole A5 far away from the bracket base 3 One end of the slant is formed to be more open, which improves the fluidity of the electrolyte in the through hole A5, ensures the uniformity of the growth of the nanowires, and increases the effective use area of the prepared nanomembrane. The substrate 1 can be made of sapphire, silicon wafer, glass, etc., and the subst...

Embodiment 2

[0033] Embodiment 2: A kind of electrochemical deposition support for preparing nanomaterials, such as Figure 1-Figure 3As shown, it includes a base 1, a front cover 2, a bracket base 3 and a conductive component 4, the base 1 is fixed through the front cover 2 and the bracket base 3, the conductive component 4 is arranged on the bracket base 3, and the base 1 is connected to the conductive component 4, and a through hole A5 is opened through the front cover plate 2, and the end of the through hole A5 away from the bracket base 3 is provided with a chamfer, and the chamfer makes the through hole A5 far away from the bracket base 3 One end of the slant is formed to be more open, which improves the fluidity of the electrolyte in the through hole A5, ensures the uniformity of the growth of the nanowires, and increases the effective use area of the prepared nanomembrane. The substrate 1 can be made of sapphire, silicon wafer, glass, etc., and the substrate 1 is coated with alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com