Transparent printing technology through macromolecule polyurethane

A printing process, polyurethane technology, applied in the field of transparent printing, can solve the problems of not being suitable for long-term storage, many independent components, etc., and achieve the effect of high market acceptance rate, fabric performance retention and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A transparent printing process utilizing polymer polyurethane of the present invention comprises in sequence: scraping printing printing paste, pre-baking, baking, alkali treatment, washing, drying, softening finishing, and setting drying.

[0019] In the transparent printing paste process, the treatment agents used are: Qingdao Feilongyuan multifunctional enhancer NANO PU 86% (mass fraction) and Qingdao Chenxintai Luxol F-HIT 14% (mass fraction).

[0020] The printing machine pressure is 2.5KGf / cm 2 .

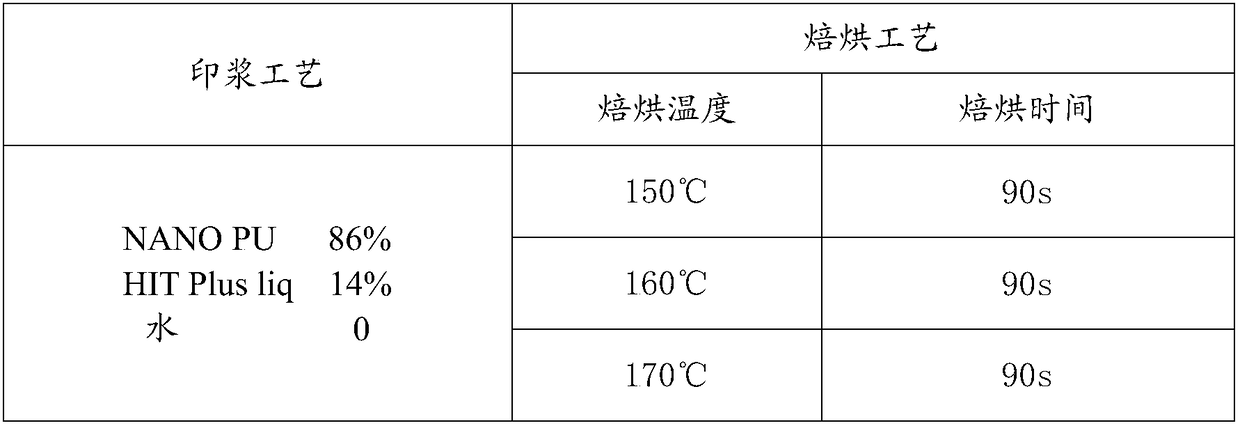

[0021] In the baking process, the baking temperature is 160° C., and the baking time is 90 s.

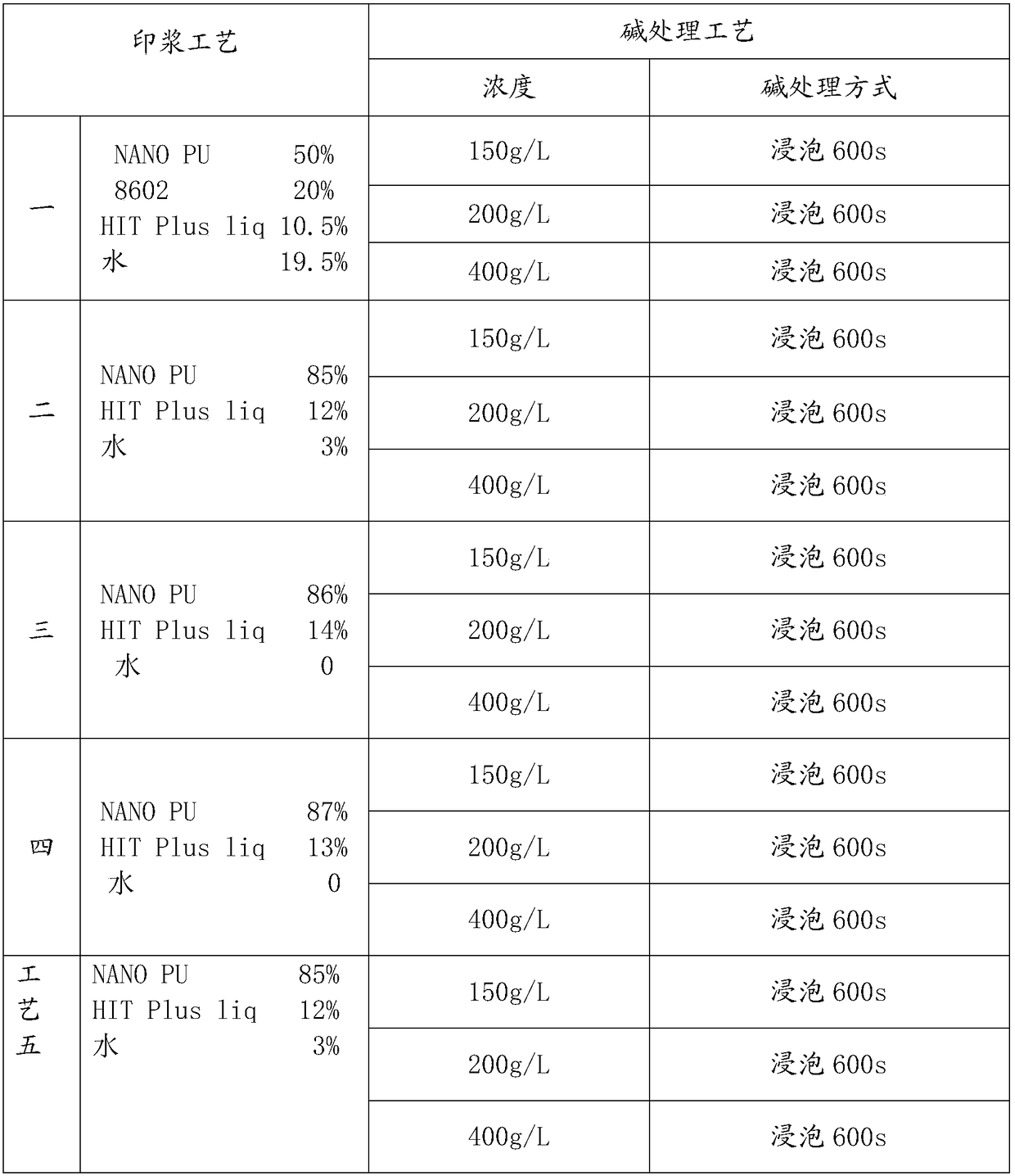

[0022] The alkali treatment process adopts 150g / L sodium hydroxide solution for 300s.

[0023] The soft finishing process adopts 3.25g / L Suzhou Liansheng smooth silicone oil 6970 and 6.75g / L Suzhou Liansheng smooth silicone oil 6973.

experiment example

[0025] Experimental cloth: C 60×60 90×80

[0026] C 40×40 96×96 (whitening)

[0027] Experimental aids: multifunctional enhancer NANO PU (Qingdao Feilongyuan), adhesive 8602 (Suzhou Liansheng), analytical pure sodium hydroxide (Yantai Shuangshuang), Luxol F-HIT (Qingdao Chenxintai), 1552 (Shanghai Shangxian), 1553 (Shanghai Shangxian), transparent wrinkling pulp PUD (Turner), transparent printing paste FS-417M (Liaoning Star), DY-TM (Foshan Davidson), smooth silicone oil 6970 (Suzhou United Sheng), smooth silicone oil 6973 (Suzhou Liansheng), softening agent XY-8807 (Binzhou Maples)

[0028] Experimental equipment: Automatic printing scraping machine (Huafang Co., Ltd.), OVEN R-1 thermal cycle oven (Xiamen Ruibi), air-compressed air-film horizontal pad dyeing test machine (Xiamen Ruibi), NDJ-8S digital viscometer (Shanghai Precision Instrument Co., Ltd.)

[0029] Test items: sample transparency, feel, wrinkle

experiment example 1

[0031] Selection Experiment of Transparent Printing Paste Auxiliaries

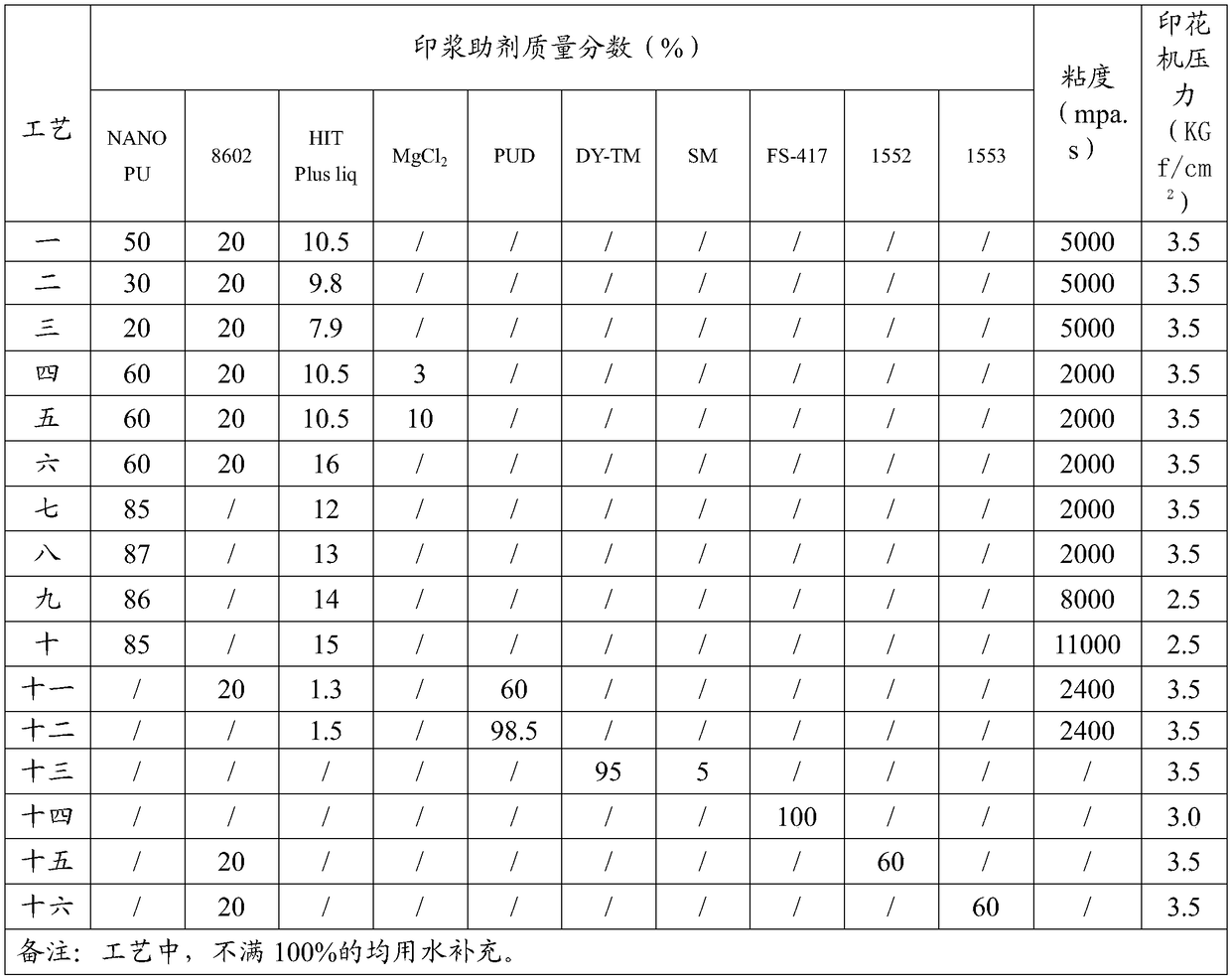

[0032] Test process: semi-finished product→scraping printing paste→drying→baking→alkali treatment→washing→drying→soft finishing→setting and drying. Under the condition of keeping other conditions uniform, the auxiliaries used in transparent printing pastes were screened. Please refer to Table 1 for the specific process.

[0033] Table 1 Transparent printing paste process

[0034]

[0035] Due to the low viscosity of the printing paste, serious penetration of the cloth surface after printing, and uneven treatment of the cloth surface, Luxol F-HIT was used to increase the viscosity of the printing paste. Through cloth sample comparison, Luxol F-HIT14% (mass fraction), printing paste viscosity 8000mpa.s, printing machine pressure 2.5KGf / cm 2 The printing effect is the best under the process conditions.

[0036] (1) 80-mesh flat screen was used for printing paste during the test.

[0037] (3) By compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com