Karst area pile foundation construction method

A construction method and technology in karst areas, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as construction slurry leakage, achieve the effects of saving engineering investment, mature and reliable construction technology, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

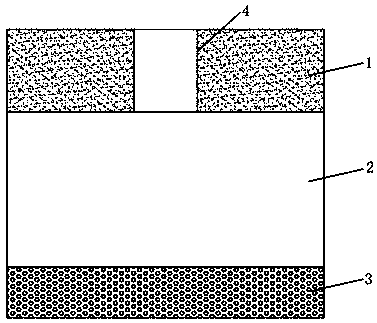

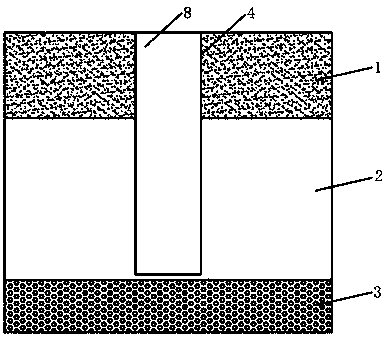

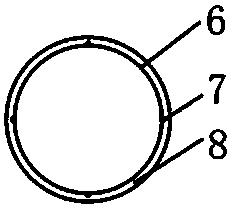

[0031] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0032] A pile foundation construction method in a karst area, comprising the following steps:

[0033] Step 1: Use a vibrating hammer to insert and punch the outer casing 4 at the designated position, control the verticality through the guiding facilities, pass through the soft plastic layer 1, and enter the hard plastic layer 2;

[0034] Step 2: Use the rotary drill to expand hole 8 to 1.0 meters from the top bedrock of the uppermost karst cave;

[0035] Step 3: In the outer casing 4, use a drilling rig to repeatedly impact the slurry to make drilling, clean the hole in time after the final hole, form a tunnel, and tamp the inner wall of the tunnel;

[0036] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com