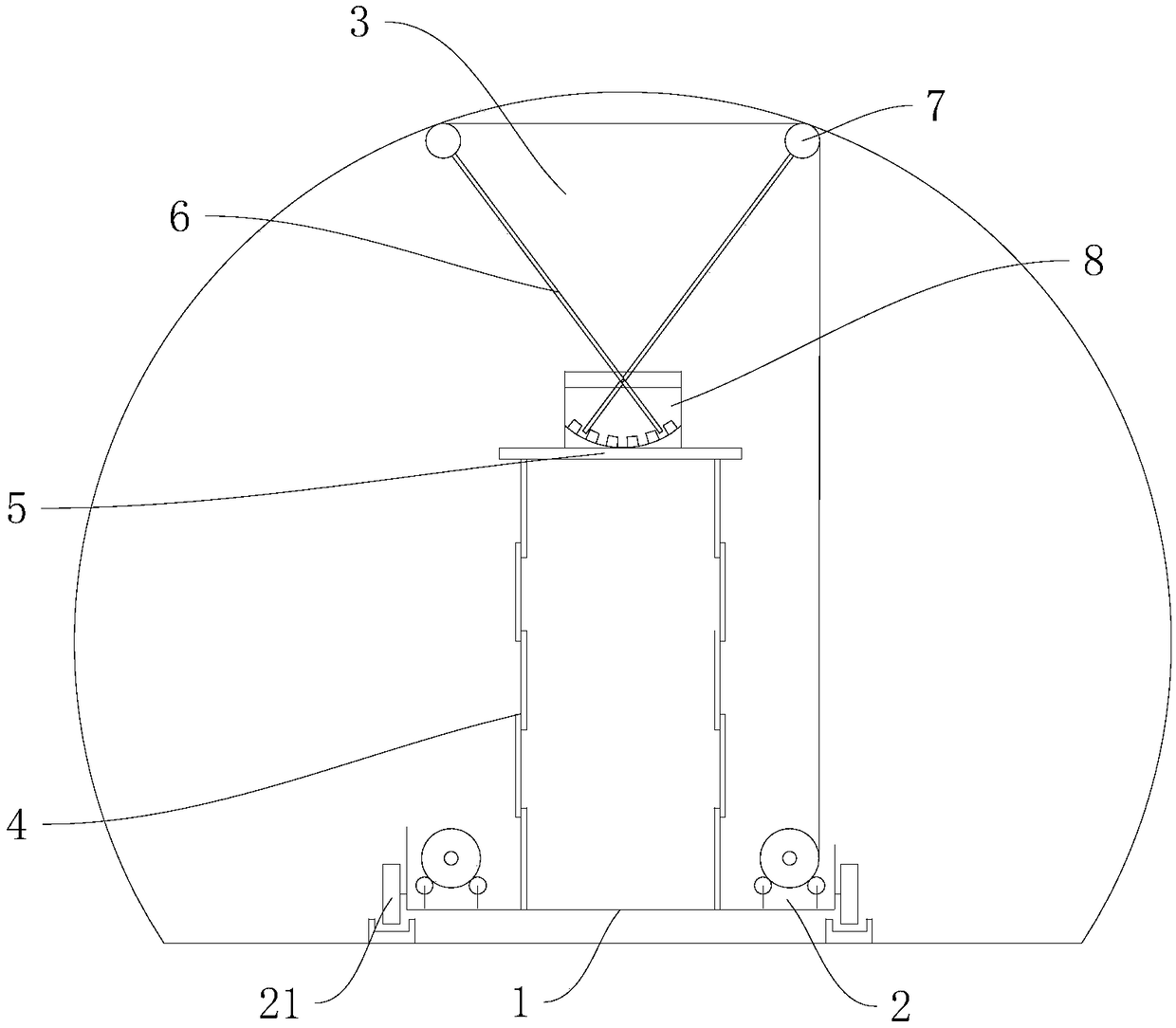

Coiled material hanging and fixing device

A technology for fixing devices and coils, applied in mining equipment, shaft equipment, shaft lining, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the effect of solving high labor intensity and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

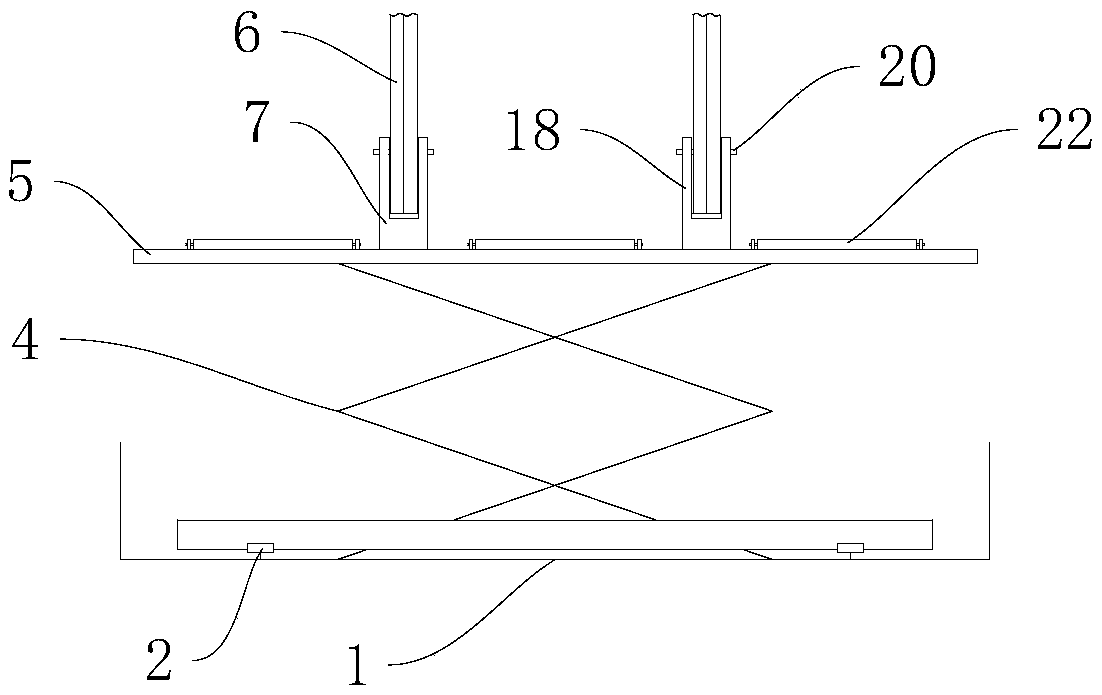

Method used

Image

Examples

specific Embodiment approach

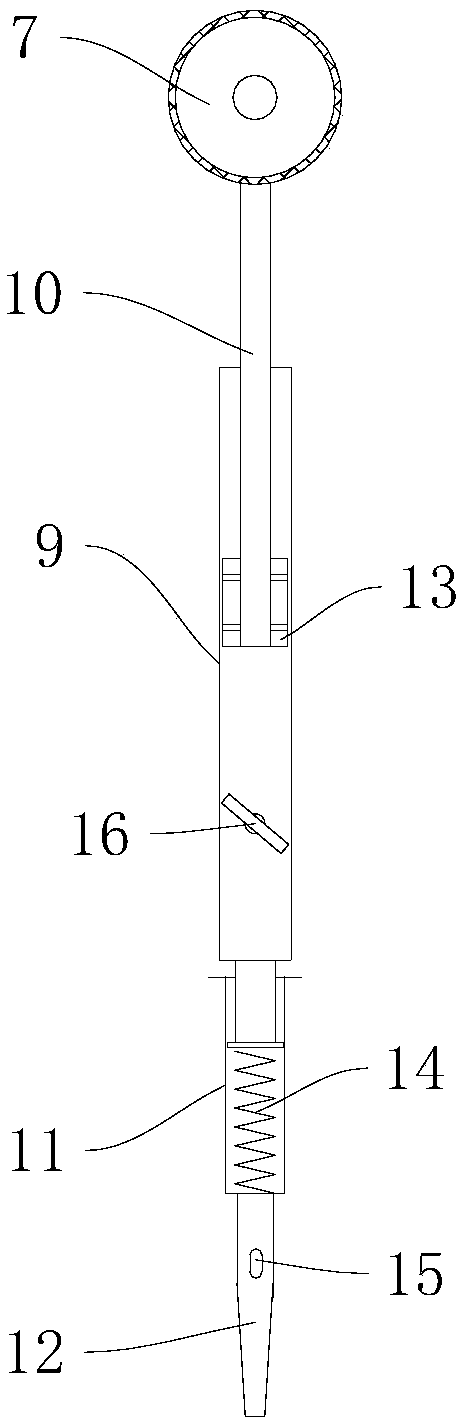

[0030] Further, see image 3 and Figure 4, as a specific embodiment of a coil hanging and fixing device provided by the present invention, the pressing rod 6 includes a first sleeve 9 with a closed lower end, a connecting rod 10, a second sleeve 11 with a closed lower end and fixed on The lower end of the second sleeve 11 shown is clamped on the positioning head 12 on the clamping assembly 8 , the upper end of the connecting rod 10 is rotatably connected to the smoothing roller 7 , and the lower part of the connecting rod 10 is passed through the first sleeve 9 , the lower end of the connecting rod 10 is also provided with a piston 13 for closing the first sleeve 9, and an air valve 16 for adjusting the air pressure in the first sleeve 9 is also provided on the side wall of the first sleeve 9. The first sleeve The lower part of the pipe 9 is passed through the second sleeve 11, the second sleeve 11 is also provided with a spring 14 that abuts against and compresses the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com