Testing method for mode I crack dynamic fracture overall process parameters under blast loading

A test method and explosion load technology, applied in the field of geotechnical engineering, can solve problems such as short crack initiation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to explain the objectives, technical solutions and advantages of the present invention more clearly and clearly, the implementation process of the present invention will be comprehensively described below in conjunction with embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not used to limit the present invention.

[0026] The application principle of the present invention will be further described below in conjunction with the drawings and specific embodiments.

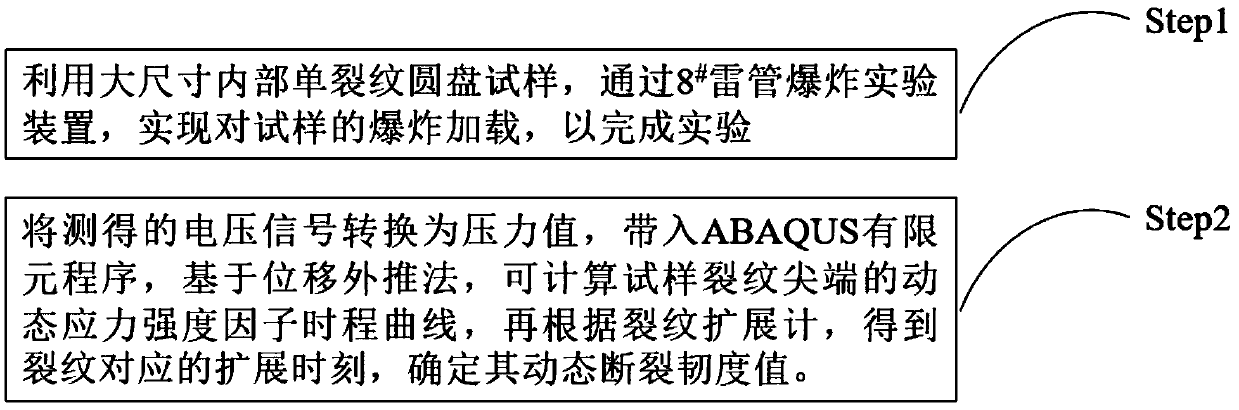

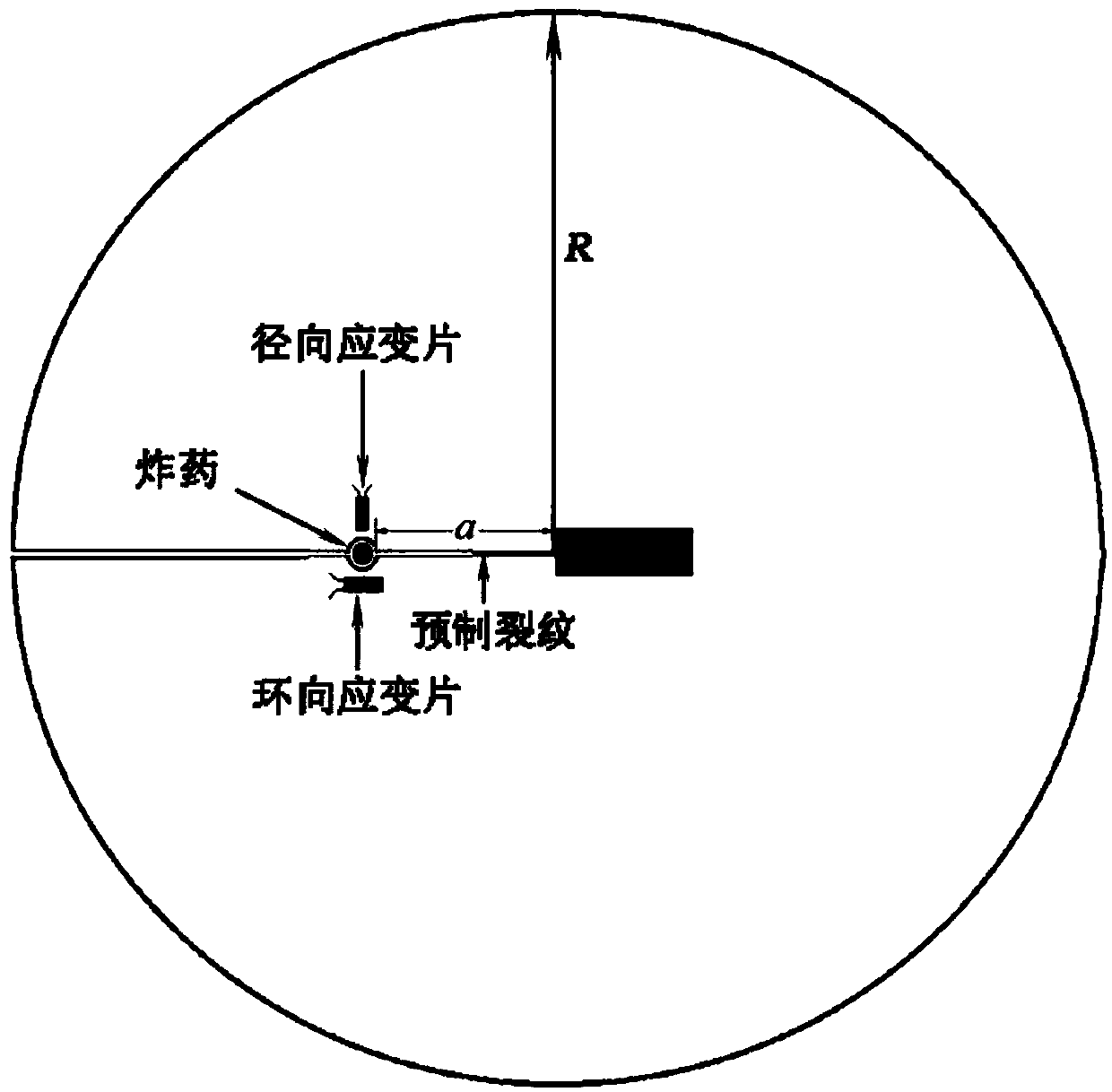

[0027] Such as figure 1 As shown, the method for testing the dynamic crack arrest toughness of mode I crack under explosive load in the embodiment of the present invention includes the following steps:

[0028] Step1: Using a large-size internal single-crack disc sample, pass 8 # Detonator explosion experimental device, which realizes the explosive loading of the sample to complete the experiment;

[0029] Step2: Convert the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com