Online large tank floor plate corrosion defect monitoring system and method

A technology for large storage tanks and storage tank bottom plates, which is applied in the direction of optical testing for flaws/defects, measuring devices, instruments, etc. It can solve the problem that it can only function in case of leakage, and achieve high detection and positioning accuracy, low cost, and Monitor the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

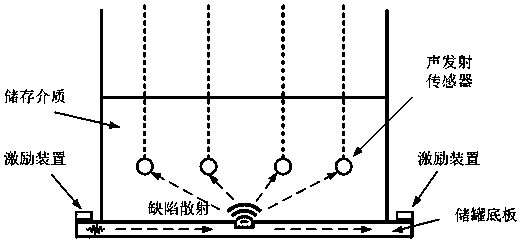

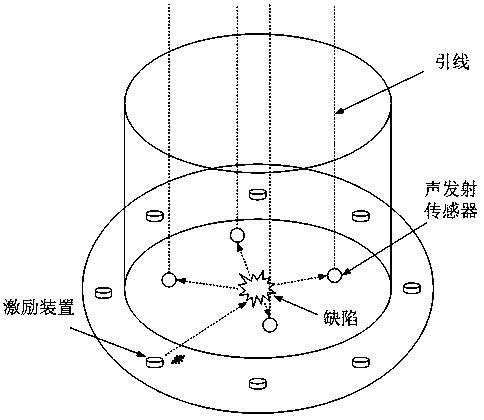

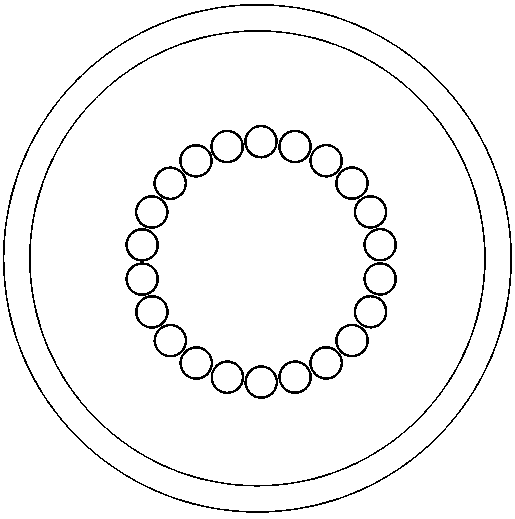

[0022] An online monitoring system for corrosion defects on the bottom plate of a large storage tank, the innovation of which is that the on-line detection system for corrosion defects on the bottom plate of a large storage tank includes: an excitation device, a sensing device and a processing device; The exposed part of the edge, or set on the outer wall of the storage tank; the sensing device adopts a distributed optical fiber sensing system or an acoustic emission sensor; when the sensing device adopts a distributed optical fiber sensing system, the sensing device of the distributed optical fiber sensing system The sensing optical fiber is arranged on the inner wall of the bottom plate of the storage tank; when the sensing device adopts an acoustic emission sensor, the acoustic emission sensor is suspended in the middle of the inner cavity of the storage tank through a suspension cable; the signal output part of the sensing device is connected with the processing device.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com