Portable feed granulation device for livestock breeding

A portable, granulating technology, applied in the fields of feed, application, food science, etc., can solve the problems of high manufacturing cost, inability to move, and inability to move the feed machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

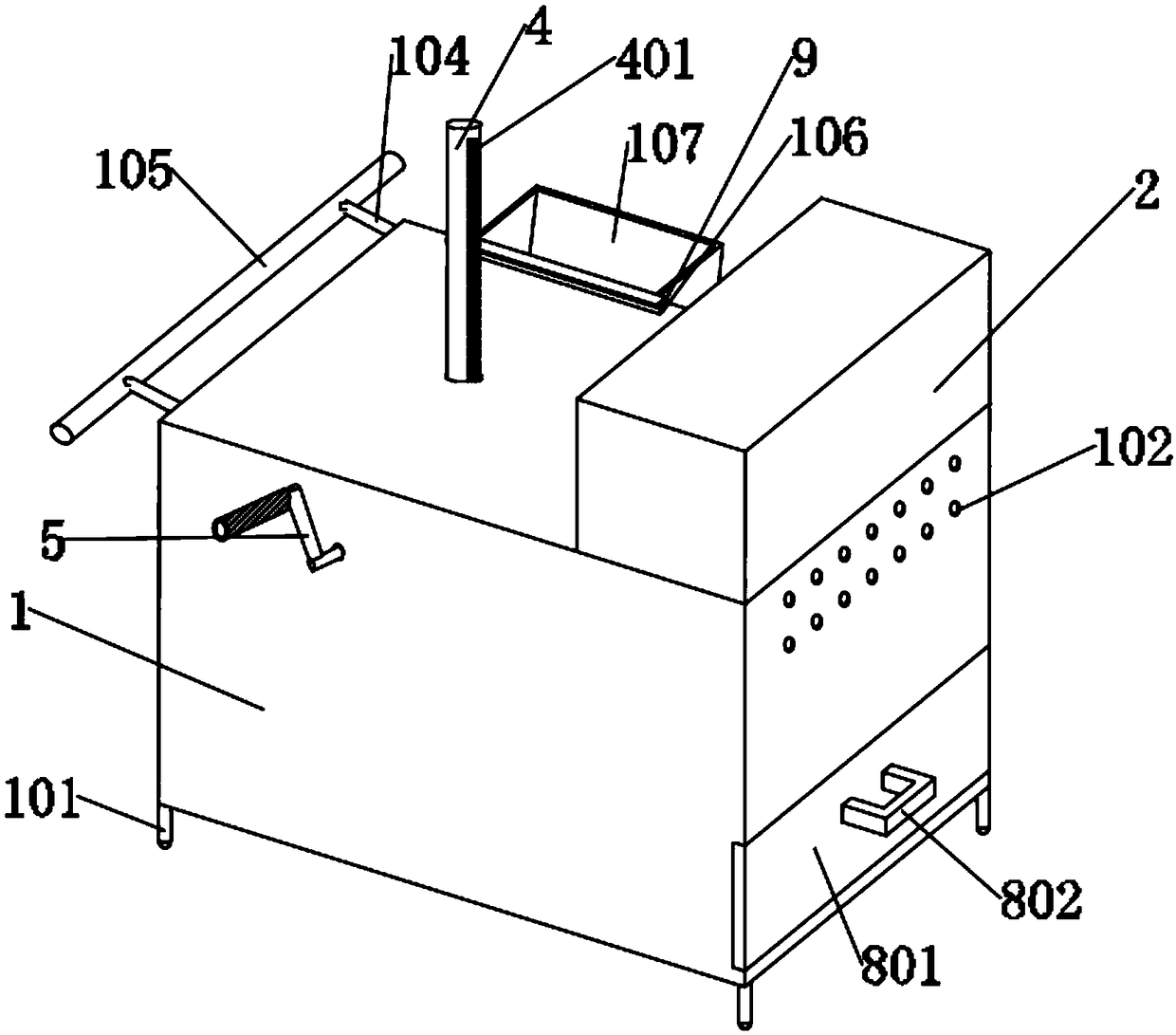

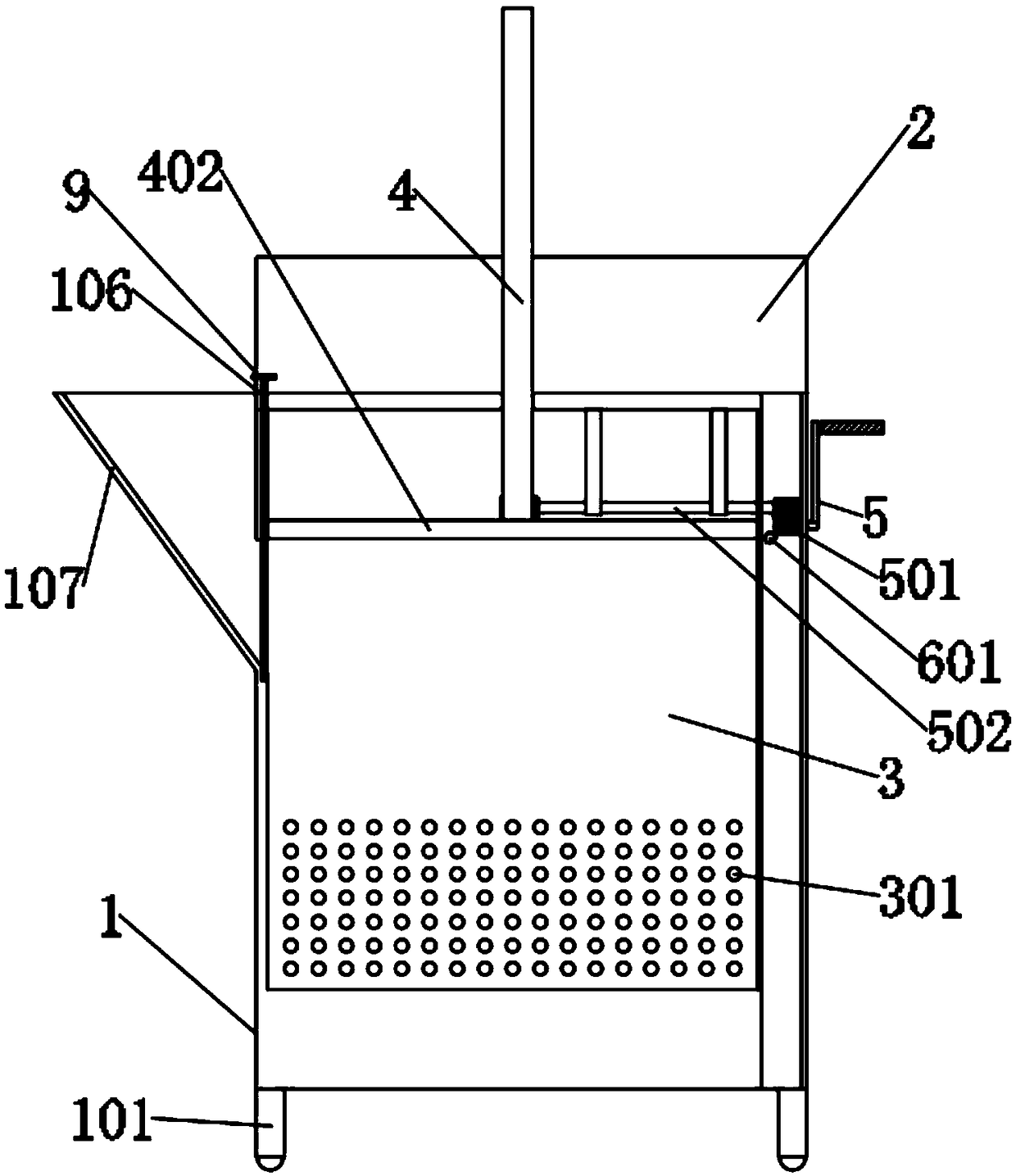

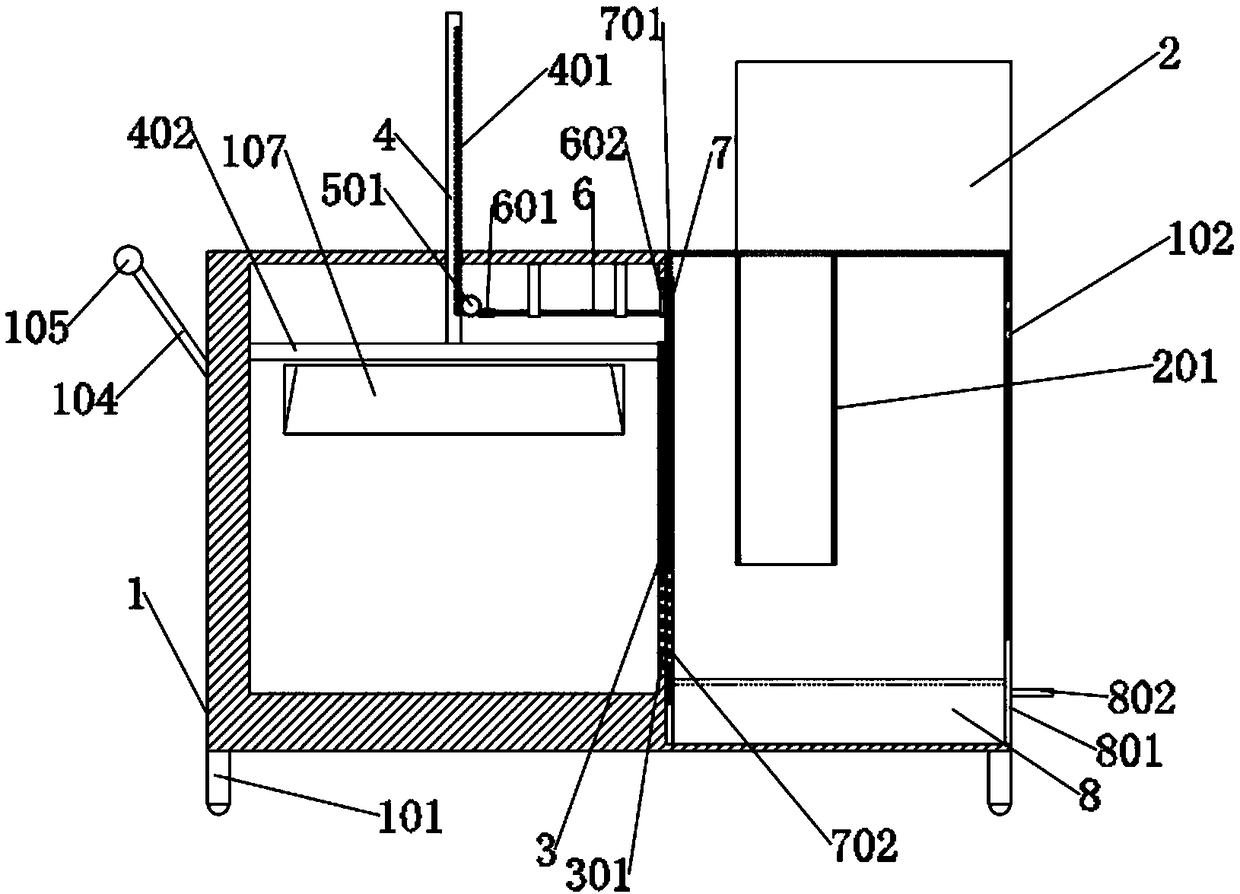

[0033] as attached figure 1 to attach Figure 9 Shown:

[0034]The invention provides a portable feed granulation device for animal husbandry, comprising a main body 1, a universal wheel 101, a cooling hole 102, a T-shaped chute 103, an extension rod 104, a pusher 105, an insertion groove 106, a feeding port 107, and a drying air Machine 2, return flow cover 201, vertical plate 3, discharge hole 301, cutout 302, lower pressure column 4, lower pressure latch 401, lower pressure plate 402, hand crank 5, internal gear 501, double-headed gear rod 502, Transmission rod 6, transmission gear 601, cam 602, moving plate 7, spring 701, granulation hole 702, baffle plate 703, sliding edge 704, drawing box 8, panel 801, handle 802 and inserting plate 9; the main body 1 It is a rectangular internal hollow structure, and the bottom angle position of the main body 1 is installed with a universal wheel 101 by welding, and the side of the main body 1 is installed with a pusher 105 through an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com