Small-dosage organic material purification method and equipment

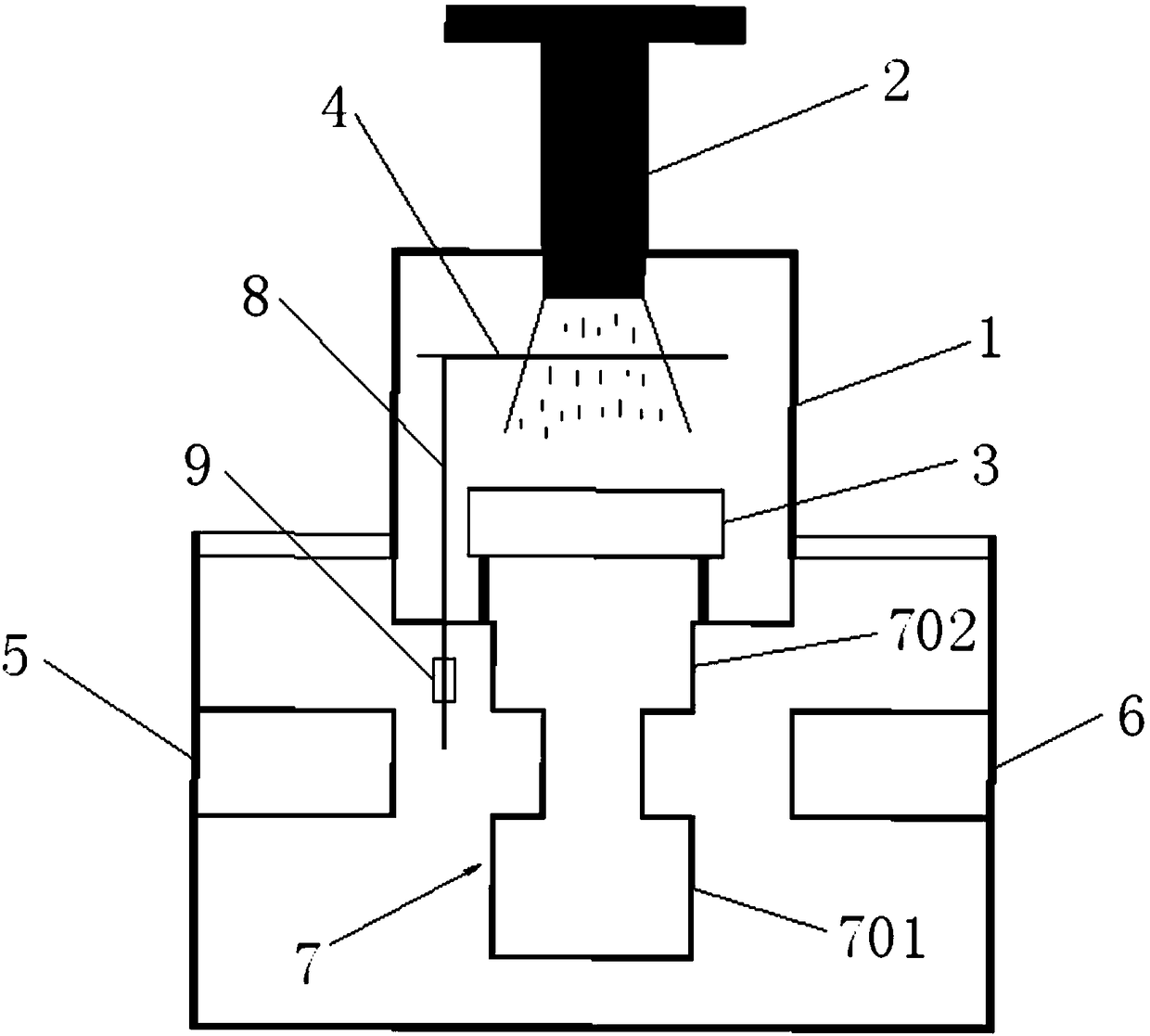

A technology of organic materials and purification methods, applied in separation methods, chemical instruments and methods, boiling devices, etc., can solve the problems of large surface area of collection area, impossibility of purification of small doses of source materials, time-consuming, etc., and achieve good deposition effect, Efficient purification and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

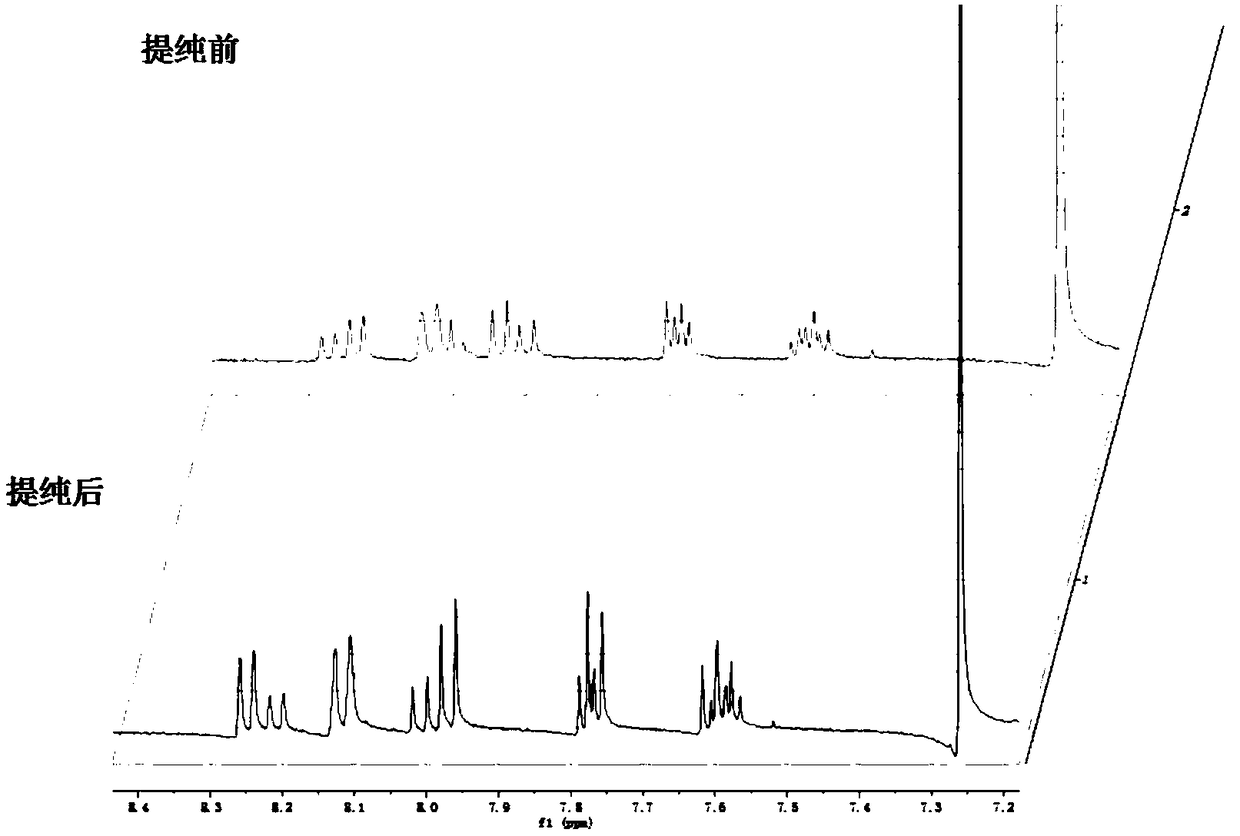

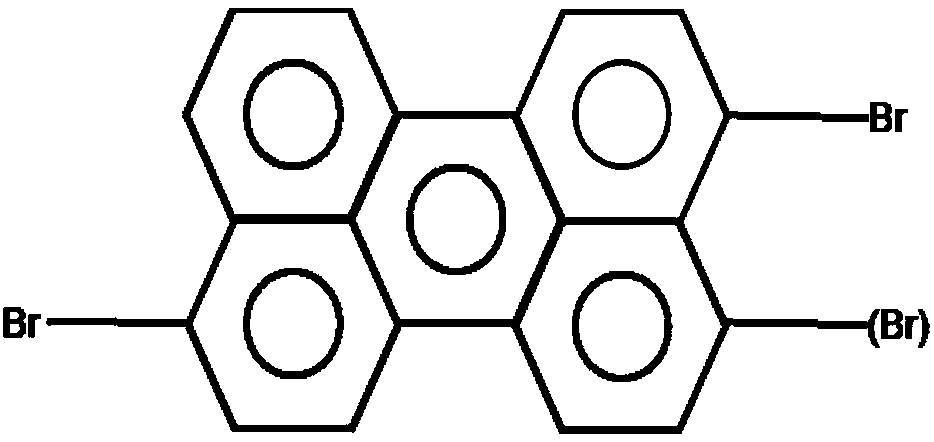

[0042] This example provides a method for purifying a self-designed and synthesized small-dose organic material—dibromoperylene, whose chemical formula is C20H10Br2, and whose structural formula is shown below.

[0043]

[0044] As a derivative of perylene, dibromoperylene has excellent light stability, thermal stability and chemical stability, and a large π-π conjugated electronic structure, which makes it have important research value in photoelectric performance.

[0045] By surface in-situ reaction method, dibromoperylene can be used as a precursor to synthesize graphene nanobelts. The purity of dibromoperylene plays a decisive role in the performance of nanobelts, so dibromoperylene needs to be purified before the experiment.

[0046] Adopt the purification equipment of the present invention to carry out the step of purification as follows:

[0047] (1) Sample preparation: first weigh a certain mass (0.0083g) of dibromoperylene molecules, then place it in the evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com