Emergent braking method for testing system of VOCs (Volatile Organic Compounds) molecular-sieve rotary wheels

An emergency braking and testing system technology, applied in separation methods, chemical instruments and methods, analytical materials, etc., can solve the problems of frequent replacement, easy smoldering, difficult regeneration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

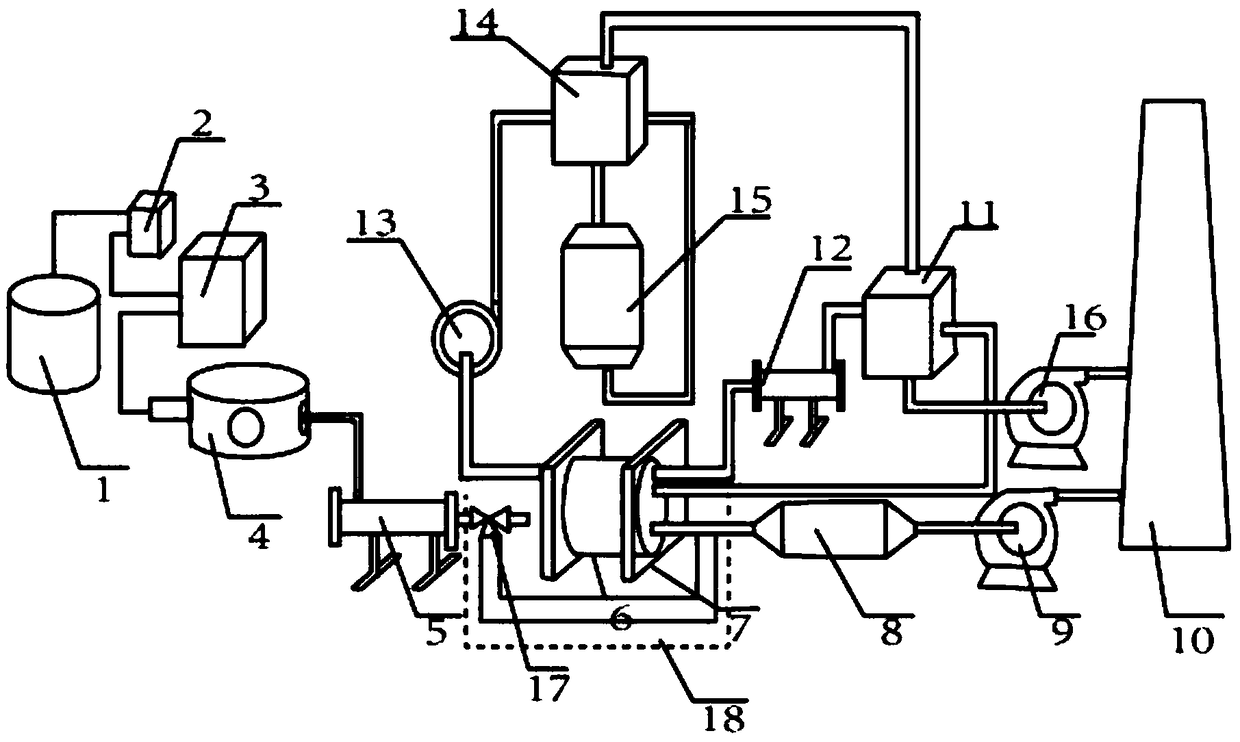

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] A kind of VOCs molecular sieve runner testing system of the present invention uses emergency braking method, comprises the following steps:

[0019] (1) The liquid solvent in the solvent tank 1 enters the main equipment 3 of the VOCs steam generator through the action of the plunger high-pressure infusion pump 2, and the solvent is converted into VOCs gas inside the main equipment 3 of the VOCs steam generator;

[0020] (2) VOCs gas enters the mixing bellows 4 and mixes with the air entering the mixing bellows 4 to form VOCs waste gas to be treated; the inlet pipes on the left and right sides of the mixing bellows 4 are provided with valves at the inlet pipes, and the valves are manually adjusted by the turbine and worm valve;

[0021] (3) VOCs exhaust gas enters the pipeline heater 5 to adjust the constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com