A kind of graphene dry stripping device

A peeling device and graphene technology, applied in grain processing, etc., can solve the problems of low production efficiency and product quality, and achieve the effects of increased probability of shear peeling, easy shearing, and large relative speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

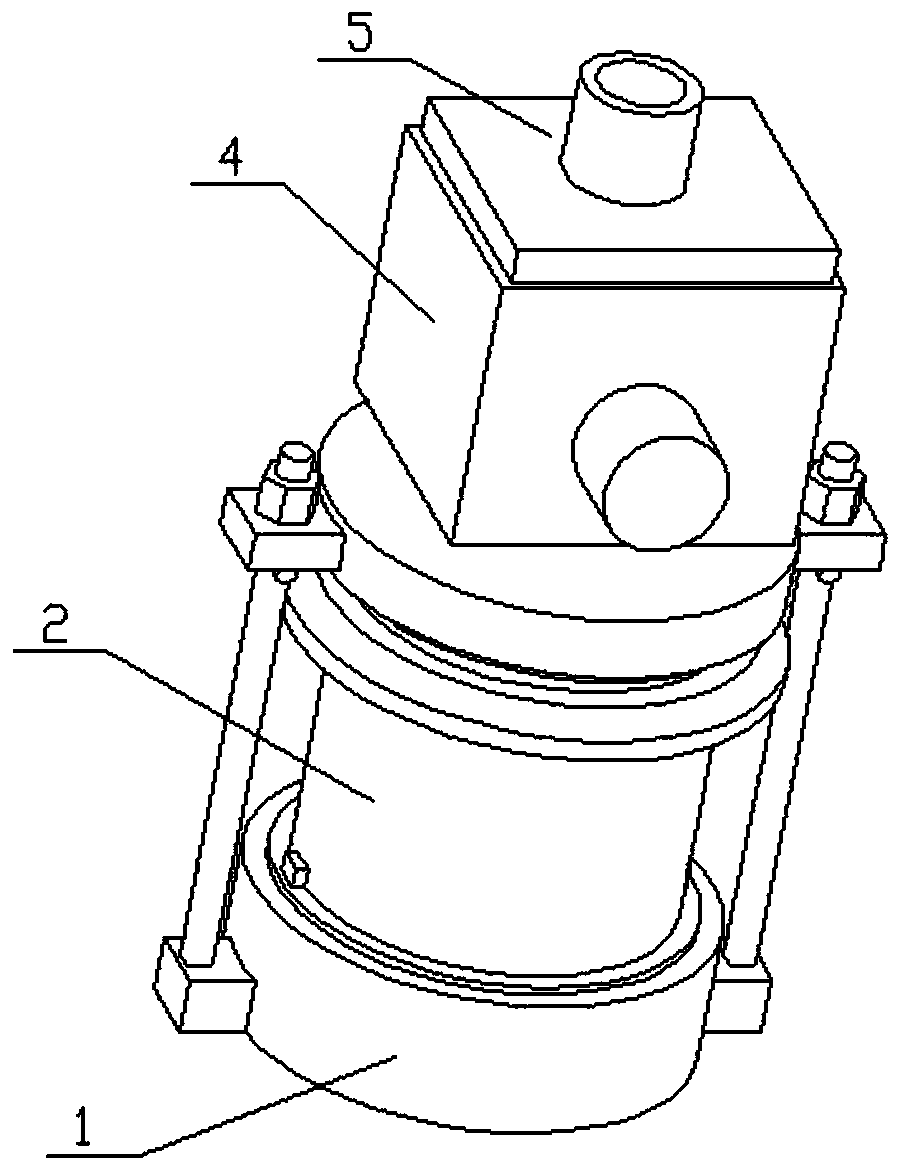

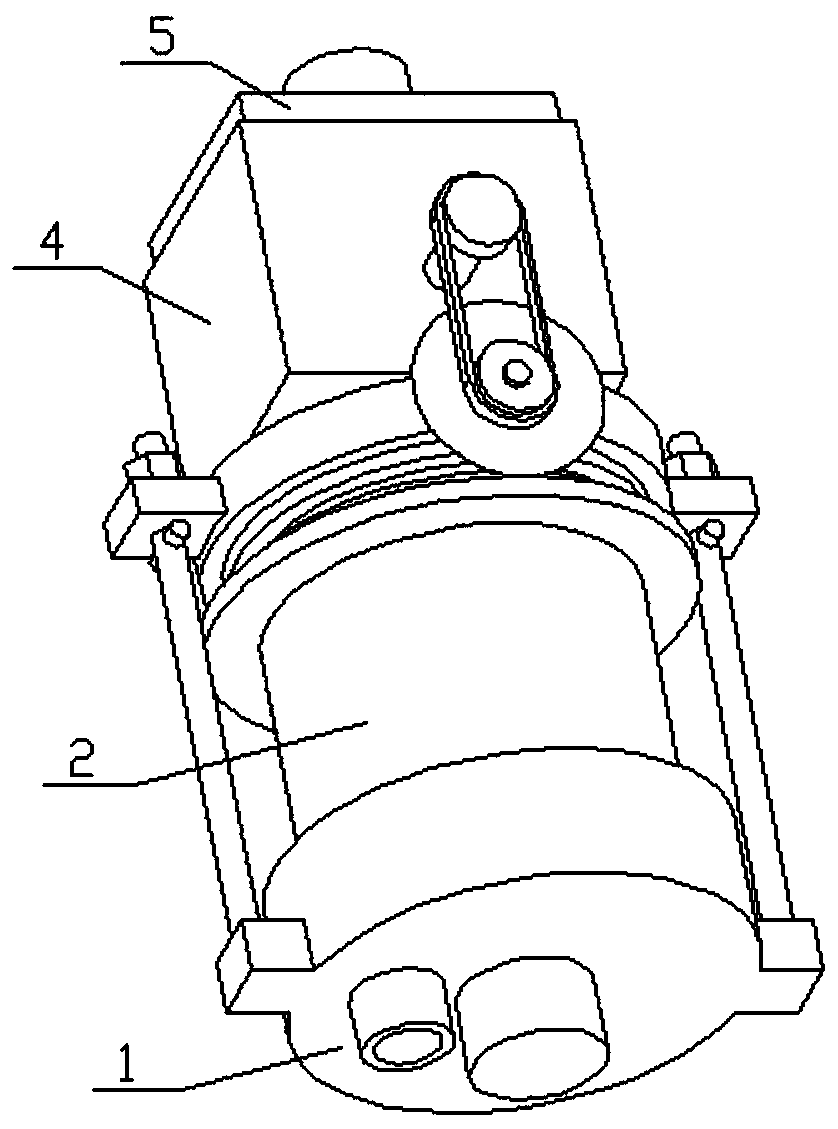

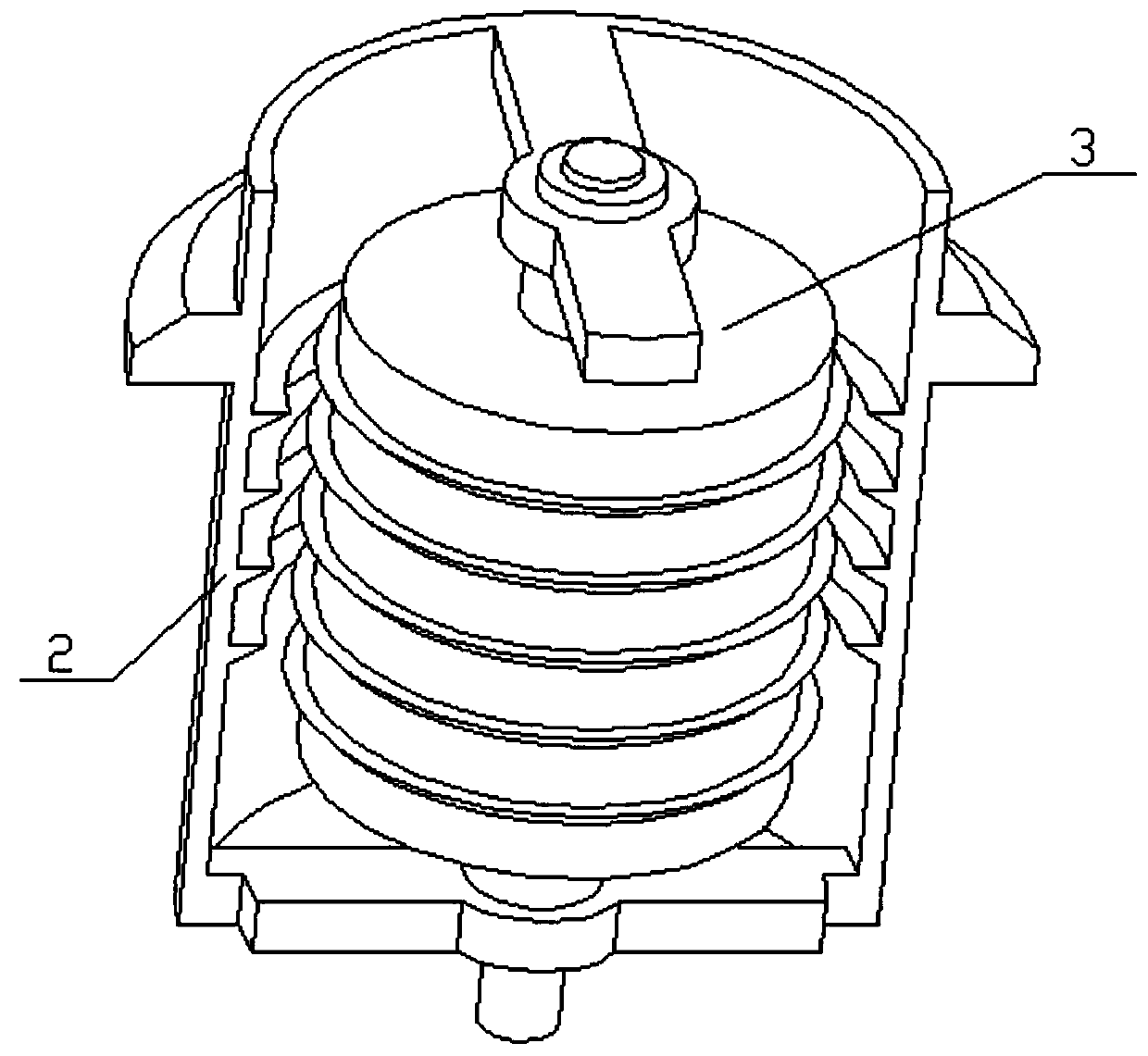

[0031] Combine below Figure 1-14 To illustrate this embodiment, the present invention relates to the technical field of graphene production, more specifically a graphene dry stripping device, including a bottom assembly 1, a middle cylinder assembly 2, a transverse shearing member 3, and a vertical shearing assembly 4 And the top cover assembly 5, the air pump introduces the airflow mixed with the graphite dry powder raw material into the gap, and the graphene is dispersed by the airflow instead of the traditional solvent, and the graphite sheet is first sheared horizontally and then longitudinally, so that the graphite dry powder raw material The probability of being sheared and peeled off by the shearing blade is greatly improved without the aid of solvents; in the present invention, the middle cylinder 2-1 and the vertical rotating column 3-1 can rotate in opposite directions, so that the relative rotational speed of the vertical rotating column 3-1 Larger, easier to shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com