Washing device for automobile decoration panel production

A technology for automobile decoration and cleaning device, which is applied in the direction of cleaning method using liquid, drying gas arrangement, cleaning method and utensils, etc., can solve the problems of only cleaning the upper surface of the sample, low cleaning efficiency, and troublesome operation, etc. The structure is simple and effective, the degree of automation is improved, and the cleaning efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

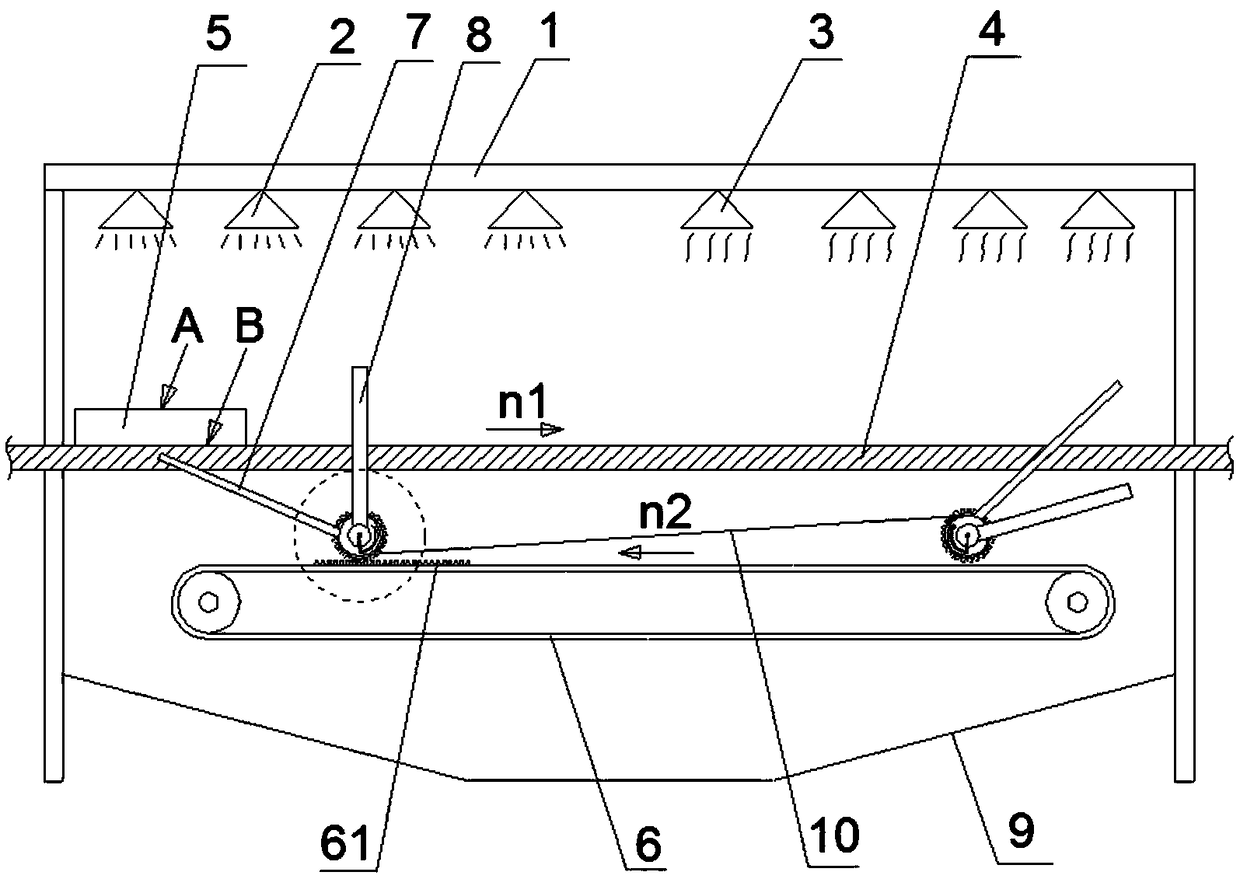

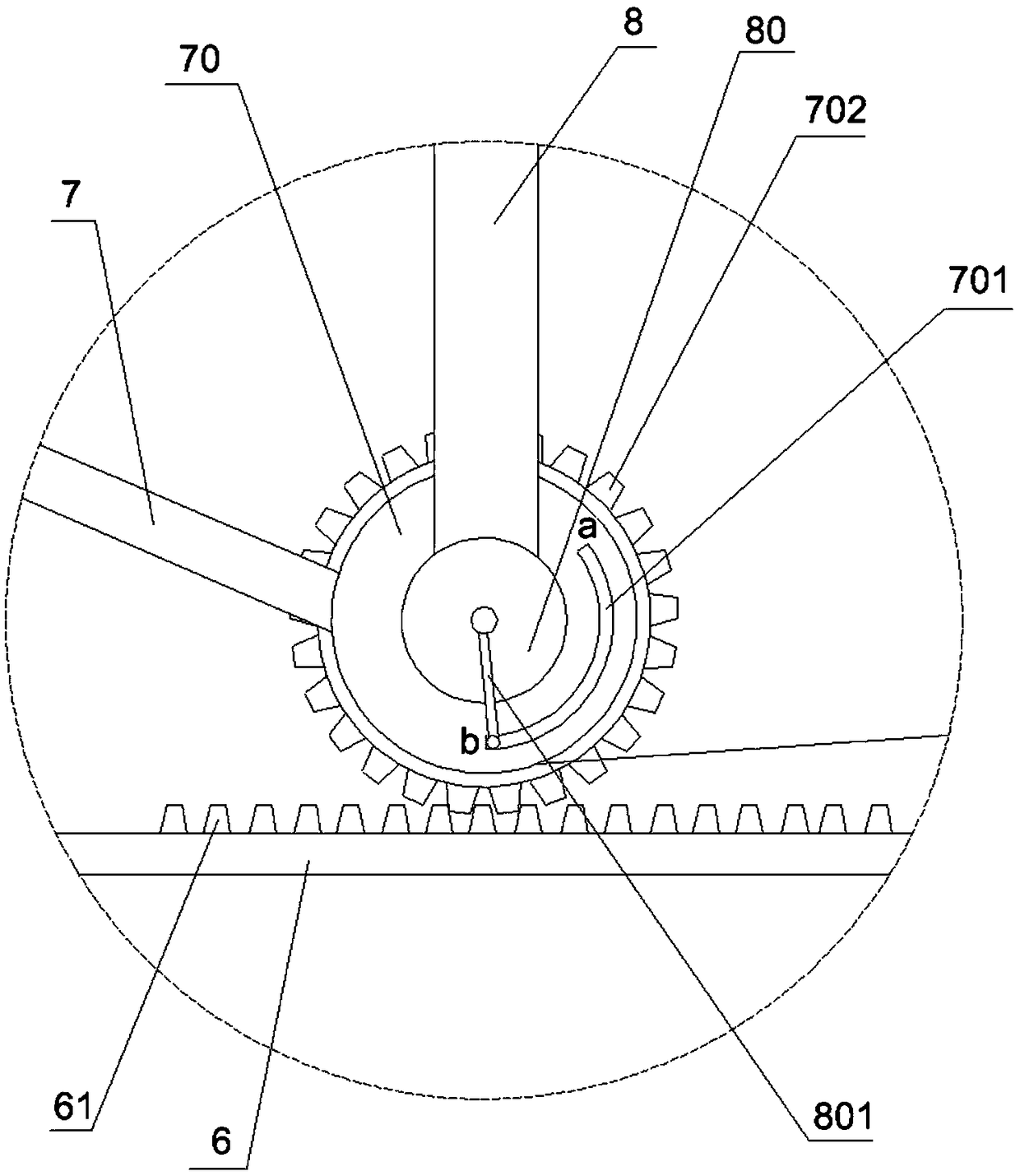

[0021] The reference signs in the drawings of the description include: frame 1, spray pipe 2, air spray pipe 3, conveyor belt 4, sample 5, synchronous belt 6, drive tooth 61, flip plate 7, first rotating shaft 70, guide groove 701, Gear 702, support plate 8, second rotating shaft 80, rotating rod 801, sewage collection tank 9, rope 10.

[0022] Such as figure 1 and figure 2 As shown, the cleaning device for automobile decorative panel production of the present embodiment comprises a frame 1, a conveyor belt 4 is installed on the frame 1, and a spray pipe 2 and a shower pipe 2 are distributed along the conveying direction of the conveyor belt 4 on the frame 1 above the conveyor belt 4. The air spray pipe 3, the conveyor belt 4 and the collection tank are also provided with a cleaning and turning mechanism and an air-jet turning mechanism. The cleaning and turning mechanism is located under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com