Winding mechanism of electronic cigarette heating wire winding machine

A winding mechanism and heating wire technology, which is applied in the fields of tobacco, smoker supplies, food science, etc., can solve the problems of not meeting the purchase price requirements of small enterprises, the complex structure of the automatic winding machine, which is not enough to meet the requirements, etc., and achieve the structure The effect of simplicity, low cost, and convenient winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

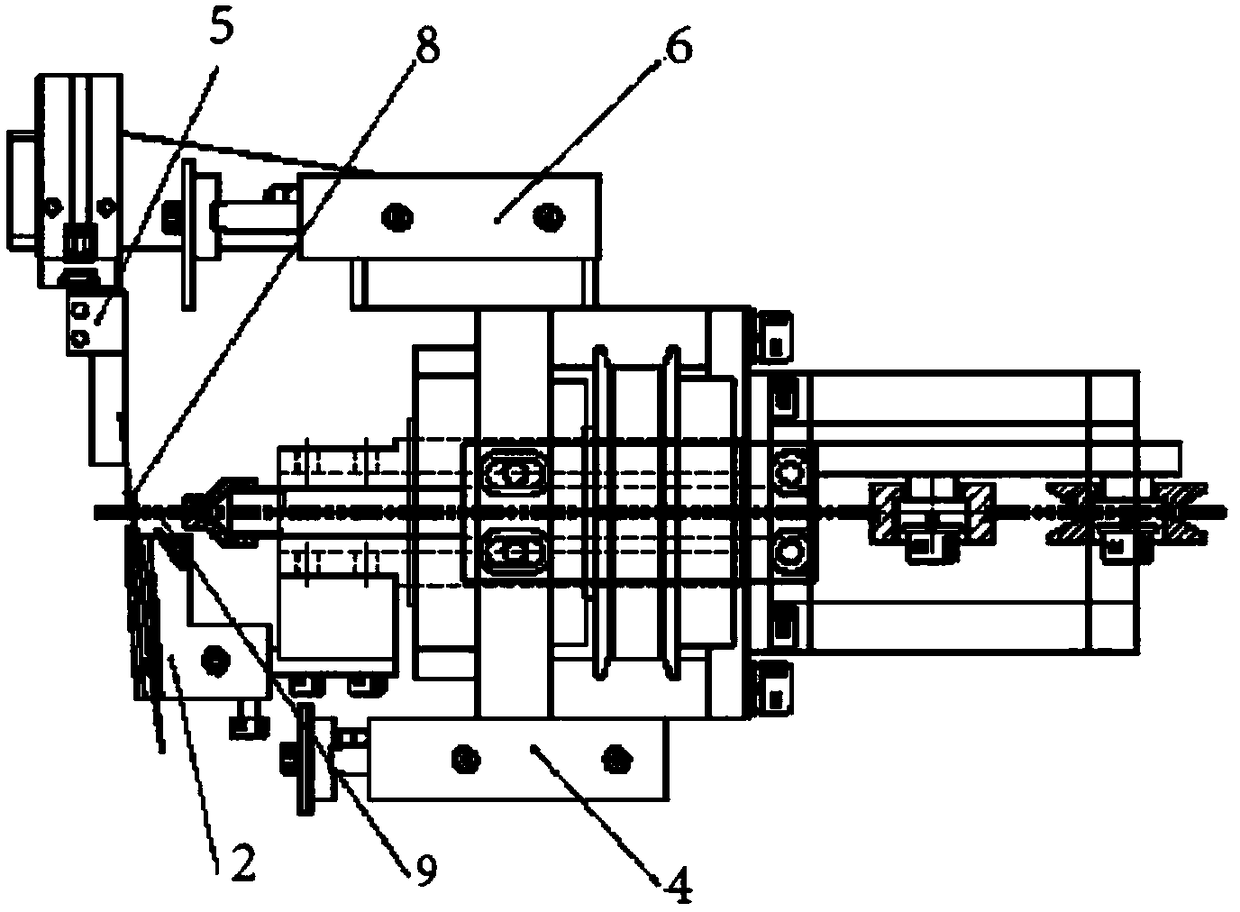

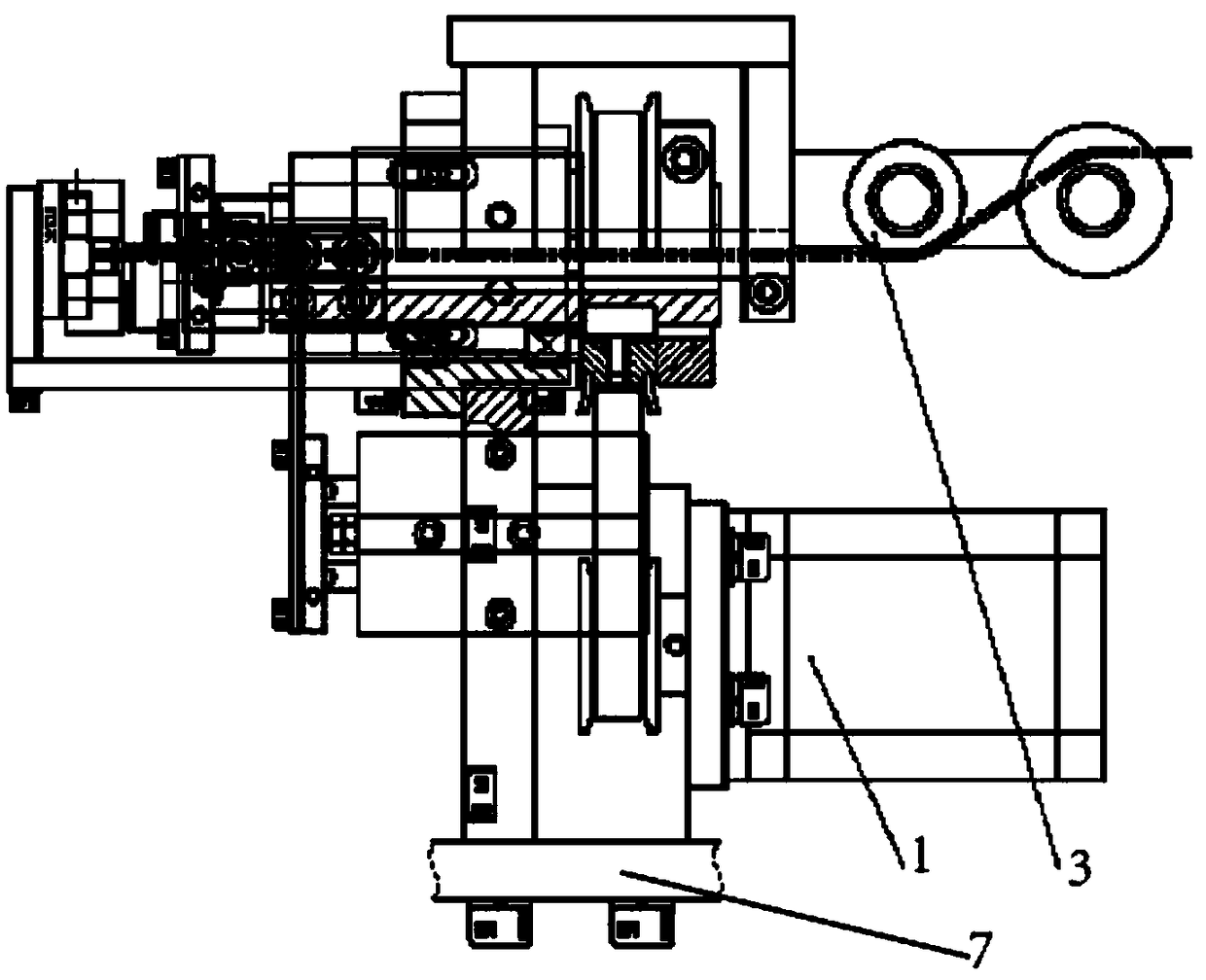

[0010] Such as figure 1 , figure 2 As shown, a winding mechanism of an electronic cigarette heating wire winding machine includes: a driving mechanism 1, a seat winding mechanism 2, a wire guide mechanism 3, a seat closing mechanism 4, a wire clamping mechanism 5, a seat opening mechanism 6, and a platen 7. Heating wire 8, fiber thread 9; the driving mechanism 1 is arranged on the platen 7, and the seat winding mechanism 2, wire guide mechanism 3, seat closing mechanism 4, wire clamping mechanism 5 and seat opening mechanism 6 are arranged on On the drive mechanism 1.

[0011] The seat opening mechanism 6 and the seat closing mechanism 4 are symmetrically arranged on both sides of the wire guide mechanism 3, the front end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com