Cooling system of direct-drive type electro-hydraulic servo crystallizer vibration control device

An electro-hydraulic servo and cooling system technology, applied in the field of cooling systems, can solve the problems of not providing a direct-drive electro-hydraulic servo crystallizer vibration control device cooling system, damaging the seals of the hydraulic transmission system, and increasing the leakage of the hydraulic pump. Achieve high reliability, no maintenance, and reduce wear and tear

Active Publication Date: 2018-11-23

CISDI RES & DEV CO LTD

View PDF9 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the working characteristics of the crystallizer vibration device are continuous and uninterrupted work, the vibration frequency is 200 times / min to 350 times / min, the servo motor drives the two-way hydraulic pump to rotate forward and reverse quickly, the internal leakage of the hydraulic pump and the high-speed rotation of the bearing It will lead to a sharp rise in the internal temperature of the hydraulic pump body. According to the test, the maximum temperature can reach above 100°C; at the same time, the external environment temperature of the crystallizer vibration device installed on the continuous casting production line is relatively high, usually above 40°C; the temperature is too high , will increase the leakage of the hydraulic pump, and at the same time affect the system performance, damage the seals in the hydraulic transmission system, and greatly reduce the life of the system. Requirements for reliable operation

None of the currently published patents provides a cooling system for a direct-drive electro-hydraulic servo crystallizer vibration control device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

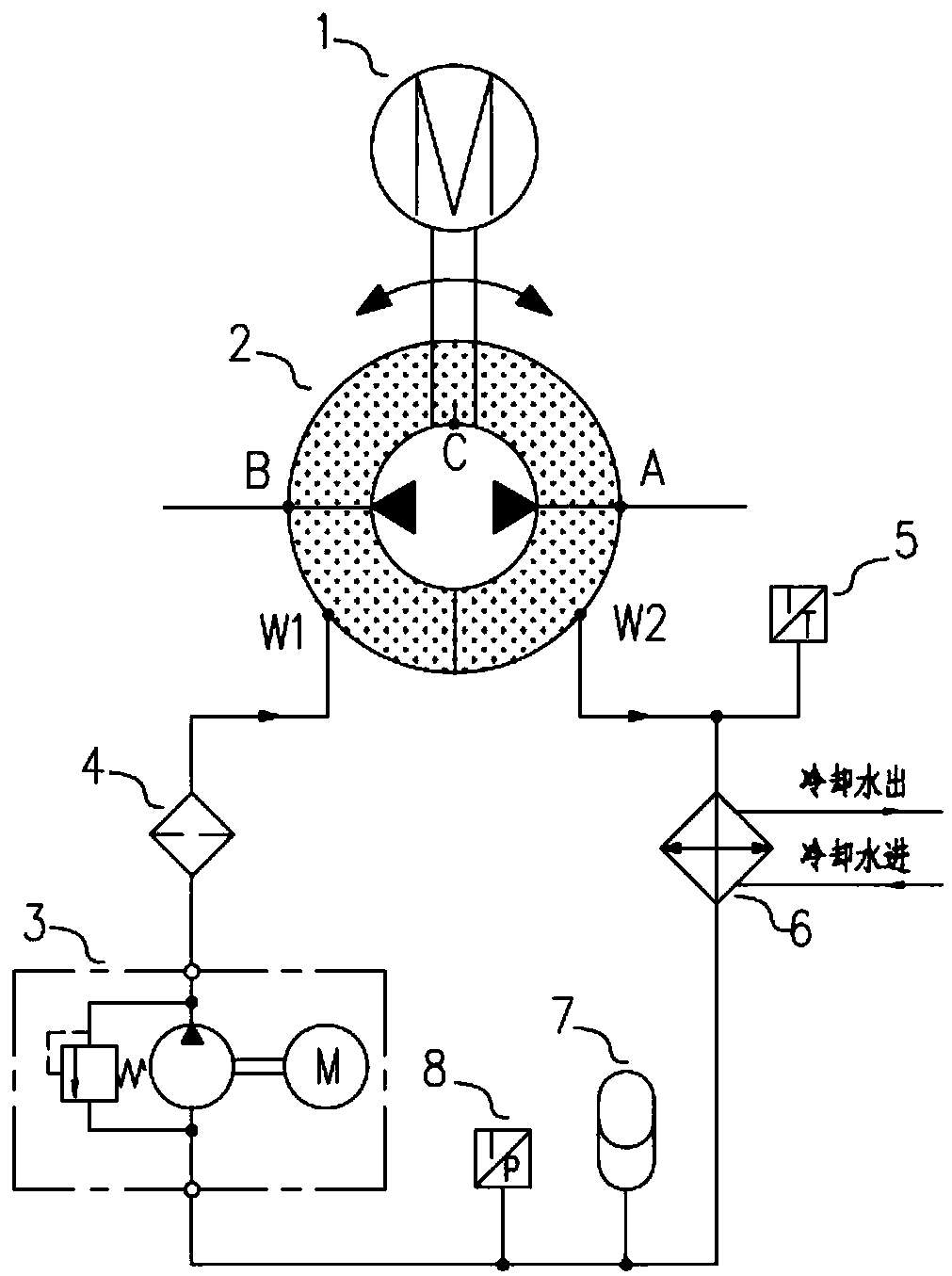

The invention relates to a cooling system of direct-drive type electro-hydraulic servo crystallizer vibration control device and belongs to the technical field of continuous casting crystallizer vibration. The cooling system comprises a driving mechanism, a bidirectional hydraulic pump, a low-pressure circulating pump set, a heat exchanger and a pressure oil tank, wherein the driving mechanism canperform drive control on the bidirectional hydraulic pump, so that the driving mechanism can forwards rotate to drive an oil outlet A of the bidirectional hydraulic pump to discharge oil and an oil suction opening C to suck oil; the driving mechanism can backwards rotate to drive an oil outlet B of the bidirectional hydraulic pump to discharge oil and the oil suction opening C to suck oil; the low-pressure circulating pump set can suck low-temperature oil liquid from the pressure oil tank and send the low-temperature oil into W1 to cool the bidirectional hydraulic pump; meanwhile, the low-temperature oil is supplemented into an inner shell body through the oil suction opening C, and high-temperature oil can flow out of a W2 opening to enter the heat exchanger for being cooled and then enters the pressure oil tank. According to the cooling system disclosed by the invention, a pressure closed-loop circulating cooling mode is utilized, and heat of a hydraulic pump body and the system canbe brought away by the low-temperature oil liquid; thus, a requirement for long-time continuous operation of a direct-drive type electro-hydraulic servo crystallizer vibration control device can be met.

Description

technical field [0001] The invention belongs to the technical field of continuous casting crystallizer vibration, and in particular relates to a cooling system of a direct-drive electro-hydraulic servo crystallizer vibration control device. Background technique [0002] As the key equipment of the continuous casting machine, the crystallizer vibration device is used to ensure that the casting slab and the copper wall of the mold do not bond during the casting process through the vibration of the mold, and to obtain a good surface quality of the slab. The existing crystallizer vibration devices are divided into mechanical vibration, hydraulic servo vibration and electric cylinder vibration according to the driving control form. The mechanical crystallizer vibration device usually uses a rotating motor and an eccentric wheel linkage mechanism to achieve sinusoidal vibration. Its disadvantages are severe mechanical wear, difficulty in achieving non-sinusoidal vibration, and vib...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22D11/16B22D11/053

CPCB22D11/053B22D11/166

Inventor 刘玉蔡春扬王永猛李新有彭晓华龙灏

Owner CISDI RES & DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com