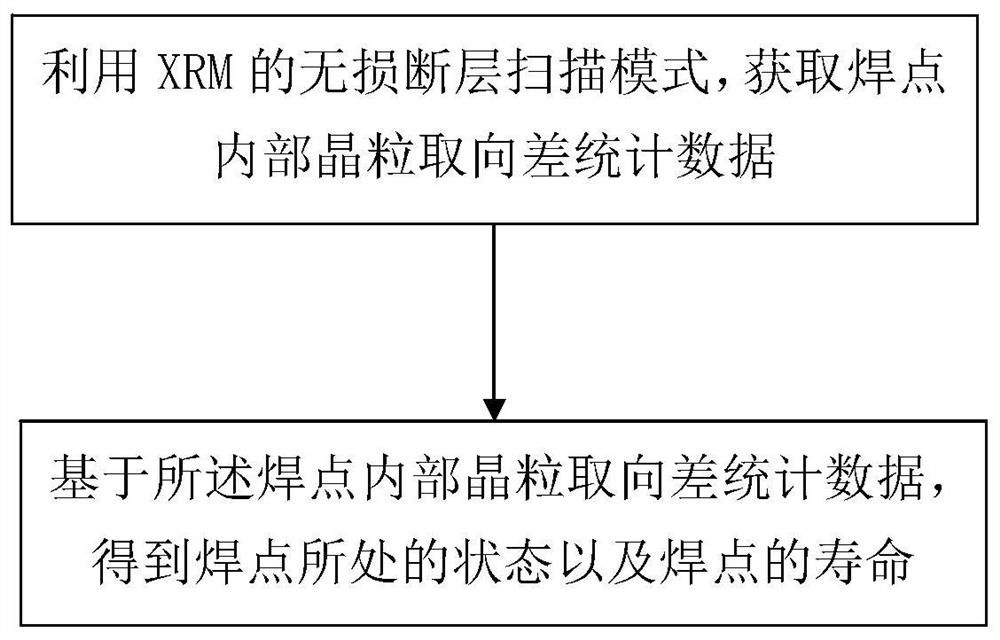

A method for evaluating the reliability of lead-free solder joints

A lead-free solder joint reliability technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as unsuitable lead-free solder joint reliability evaluation, reduce the difficulty of sample preparation, and achieve accurate statistics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] The structure of the traditional Pb-Sn solder joint is composed of β-Sn and the Pb-rich phase surrounding it. The structure is fine, and because the Pb-rich phase is soft, the mechanical properties of the entire solder can be considered to be isotropic. . After the solder joints are lead-free, the Sn content dominates, and the solder joints are mainly composed of Sn-based solder. After reflow, the solder joints are composed of β-Sn, Ag3Sn and Cu6Sn5, of which Ag3Sn and Cu6Sn5 are evenly distributed in the β- Near Sn, it plays the role of dispersion strengthening. In addition, it is observed that the number of grains inside the lead-free solder joint is far less than that of the traditional Pb-Sn solder joint, and sometimes there is even a single grain solder joint. There are few grains and surrounded by dispersion strengthening phase. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com