Method of cutting silicon wafer

A technology for silicon wafers and cutting machines, which is applied to fine working devices, grinding machines, metal processing equipment, etc., and can solve problems such as low cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for cutting a silicon wafer, comprising the steps of:

[0041]A silicon block with a thickness of 156 mm and a cross-sectional size of 156×156 mm is selected, and the cross-sectional diameter of the diamond wire is selected to be 70 μm.

[0042] Install the crystal holder with the silicon block attached on the workbench of the silicon block cutting machine above the diamond wire mesh;

[0043] The guide wheel drives the diamond wire attached to it to move until the linear speed of the diamond wire reaches a predetermined value;

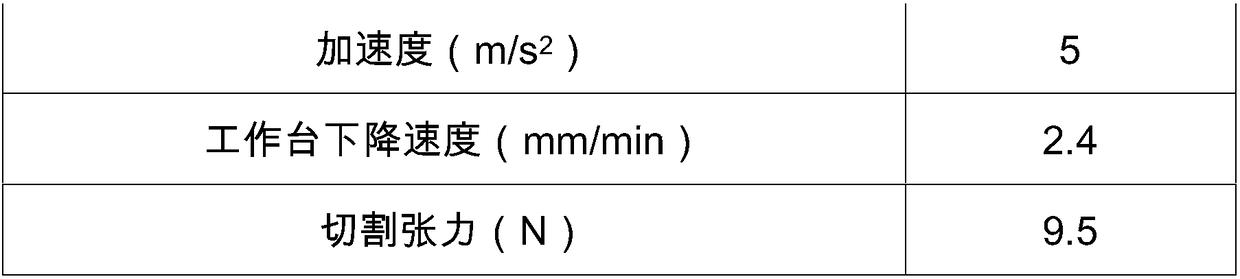

[0044] Press down the workbench, and at the same time, the guide wheel of the silicon block cutting machine drives the diamond wire to reciprocate, and the diamond wire grinds and cuts the silicon block. See Table 1 for other parameters.

[0045] Table 1

[0046] parameter

[0047] The cutting time for each cut is 130 minutes.

Embodiment 2

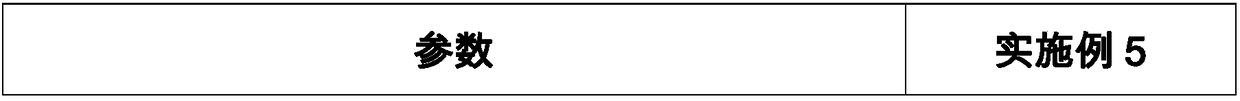

[0049] A silicon block and a diamond wire of the same size as in Example 1 are selected for use. The method for cutting silicon wafers is substantially the same as in Example 1, except that the cutting parameters are different, as shown in Table 2:

[0050] Table 2

[0051] parameter

[0052] The cutting time for each cut is 122 minutes.

Embodiment 3

[0054] A silicon block and a diamond wire of the same size as in Example 1 are selected for use. The method for cutting silicon wafers is substantially the same as in Example 1, except that the cutting parameters are different, as shown in Table 3:

[0055] table 3

[0056]

[0057]

[0058] The cutting time per cut is 113 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap