Building material lifting machine capable of achieving convenient and rapid carrying

A technology for building materials and hoists, applied in the direction of cranes, etc., can solve the problems of increasing the tediousness of work, unable to adjust the lifting grip, and single adjustable orientation, and achieves enhanced overall structural stability, strong overall structural stability, The effect of reducing labor complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

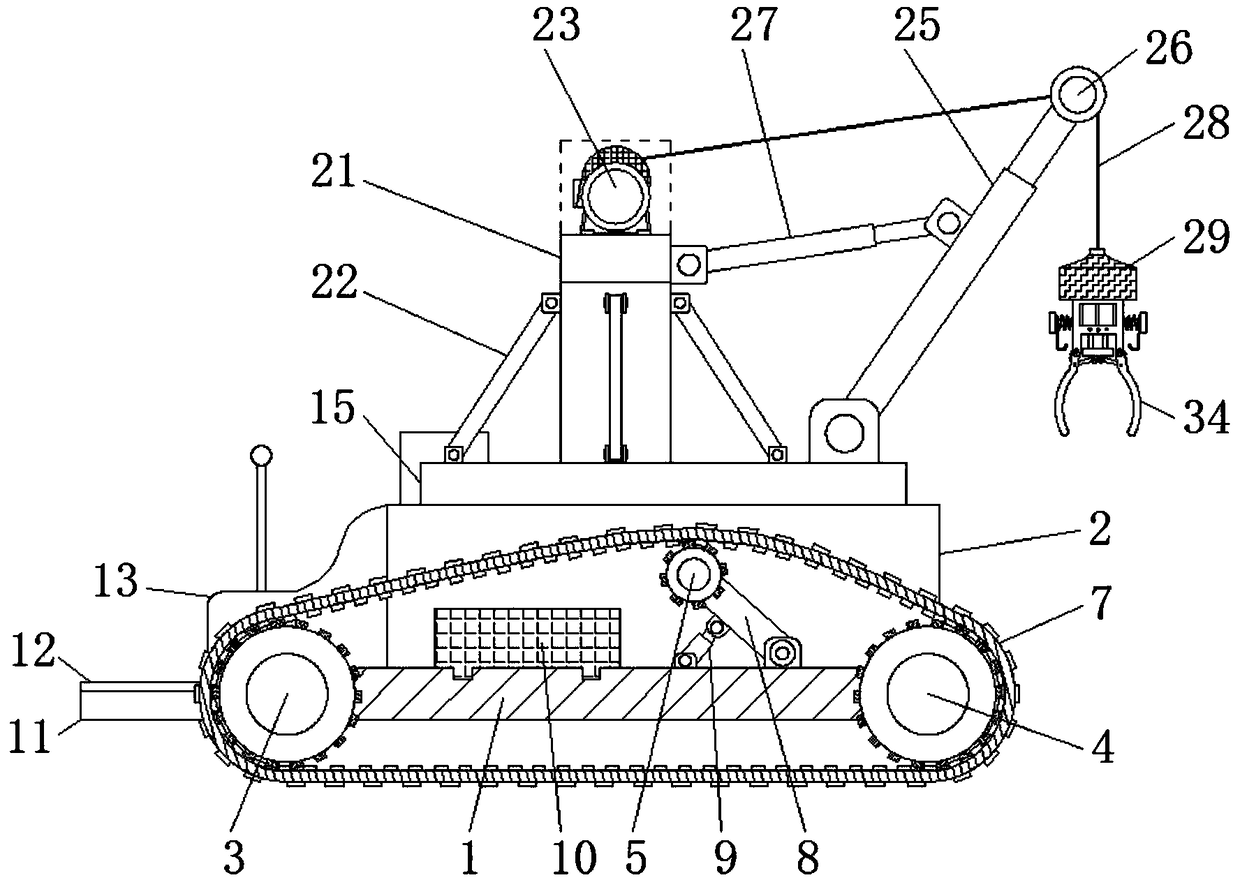

Embodiment 1

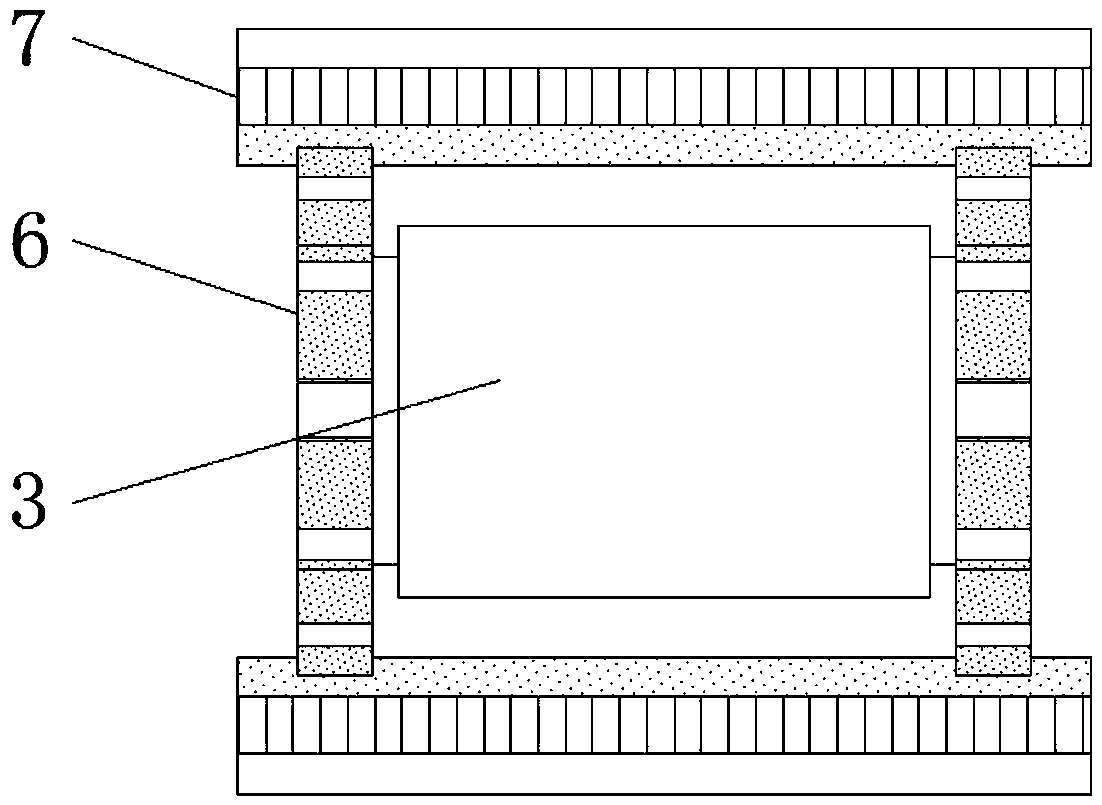

[0030] Example 1, such as figure 2 The outer sides of the middle driving wheel 3, the guide wheel 4 and the supporting sprocket 5 are equipped with meshing discs 6, and the interlocking discs 6 form a linkage structure through the track 7, and the meshing between them is used to facilitate the transmission of the track 7. as well as Figure 4 The middle storage box 14 is a detachable structure on the power box 2, and the storage box 14 includes a box cover 1401, a connecting plate 1402, an insertion rod 1403 and a handle 1404, and the outside of the bottom of the box cover 1401 is provided with a handle 1404, and the handle 1404 The rear side is provided with a plunger 1403, and the plunger 1403 is installed below the handle 1404, which is convenient for storing the tools that need to be used during the work or maintenance of the crane. The storage box 14 is magnetically connected to the bottom plate 1 through the connecting plate 1402 , and between the storage box 14 and th...

Embodiment 2

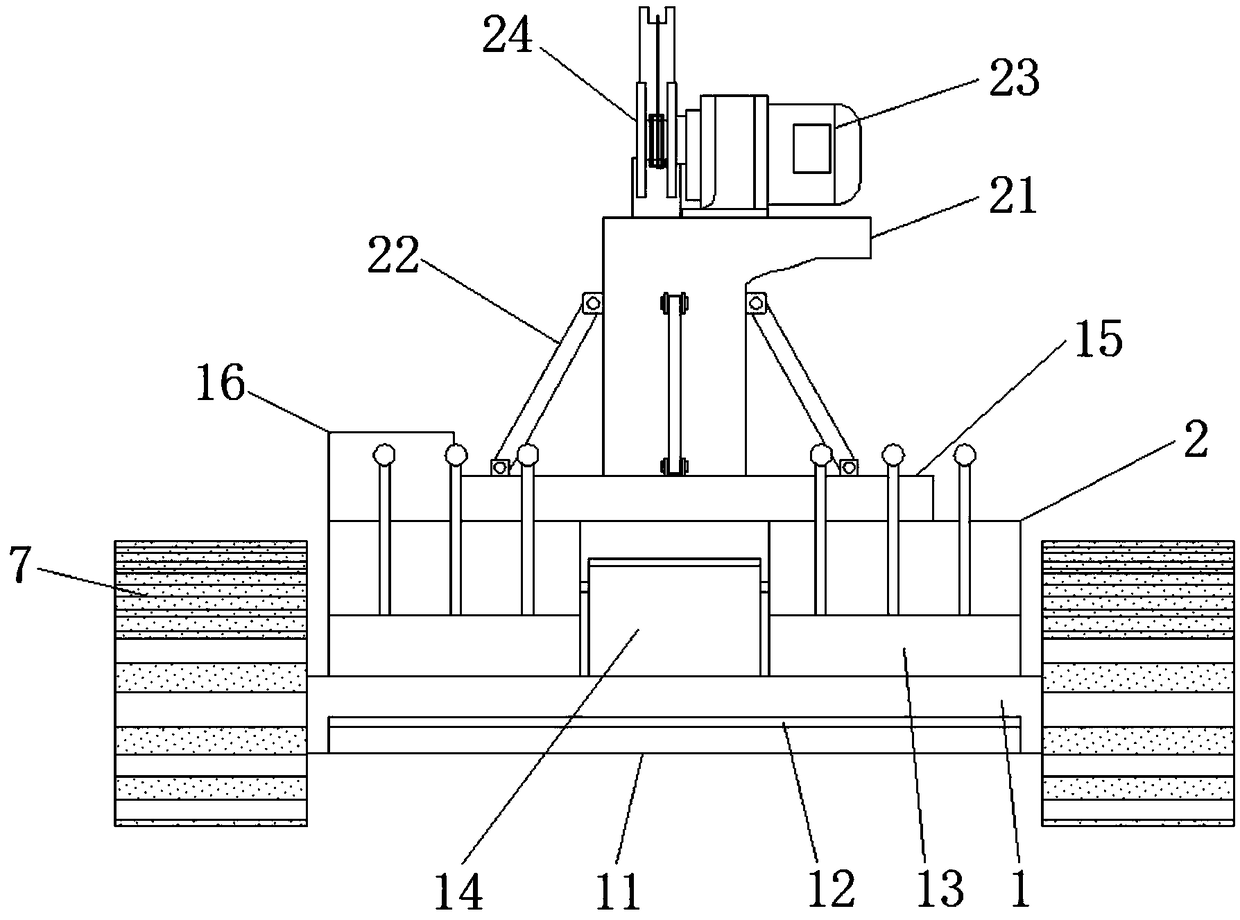

[0031] Example 2, such as Figure 5 There are two middle cabinets 16, and the cabinets 16 are installed on the outside of the chassis 15 and the top of the support column 21 respectively, and the outer walls of the cabinets 16 are arranged with ventilating grooves 17 at equal intervals, which ensures that the cabinet 16 has a pair of internal first drive motors 18 and The heat dissipation work of the second drive motor 23 is conducive to ensuring the long-term work of the first drive motor 18 and the second drive motor 23. In addition, the transmission plate 20 includes a connecting plate 2001 and a driven plate 2002, and a driven plate 2001 is installed below the connecting plate 2001. The disc 2002, the connecting disc 2001 and the driving disc 19 are engaged and connected, and the driven disc 2002 is engaged and connected with the chassis 15, and the chassis 15 is a rotating structure above the power box 2, so as to facilitate the operation of the rotation of the chassis 15 ...

Embodiment 3

[0032] Example 3, such as Figure 7 The middle transmission plate 32 is a telescopic structure inside the shell 30, and the transmission plate 32 is connected with the handle 34 through the transmission rod 33, and the structure between the handle 34 and the shell 30 is a rotating structure, which is convenient for grabbing building materials and is convenient for carrying out use, and figure 2 Among them, the reel 24 is respectively connected with the reel 26 and the electromagnetic device 29 through the first rope 28, and the electromagnetic device 29 and the shell 30 are disassembled. The cross-sectional shape and structure of the column 35 is a "T"-shaped structure, and the fixed column 35 is connected with the hook 37 through the second rope 36, which is convenient for adopting different grabbing methods according to different building materials, so that the crane can be more suitable for lifting work , which reduces labor cumbersomeness and is conducive to improving li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com