High-low pressure plate cabinet transporting-mounting vehicle

A technology for installing trucks, high and low pressure, applied in the direction of lifting devices, etc., can solve the problems of waste of manpower, time and mechanical shifts, excessive use of panel transportation time, and many types of auxiliary equipment, so as to save crane shifts and finished products Good protection effect and save waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

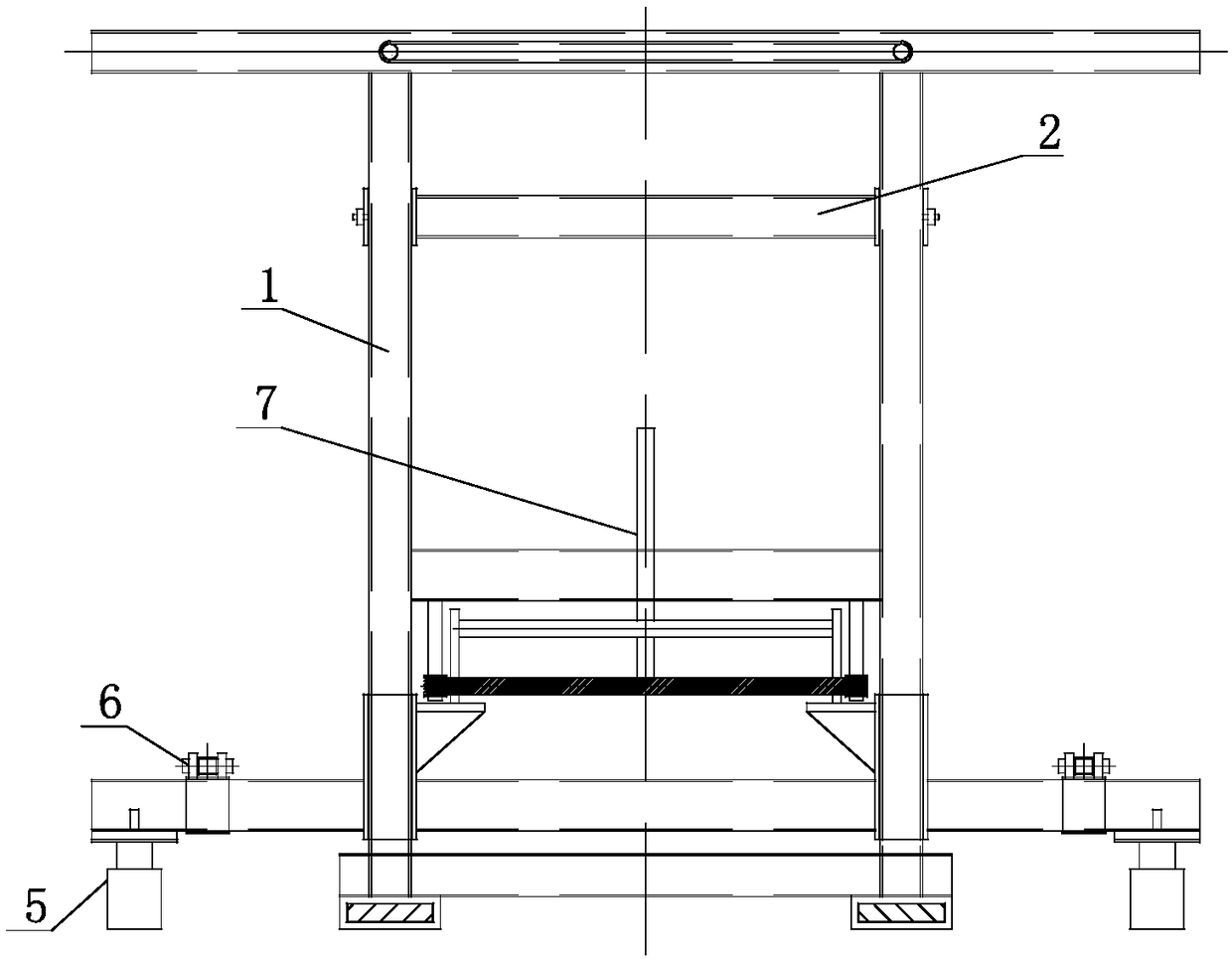

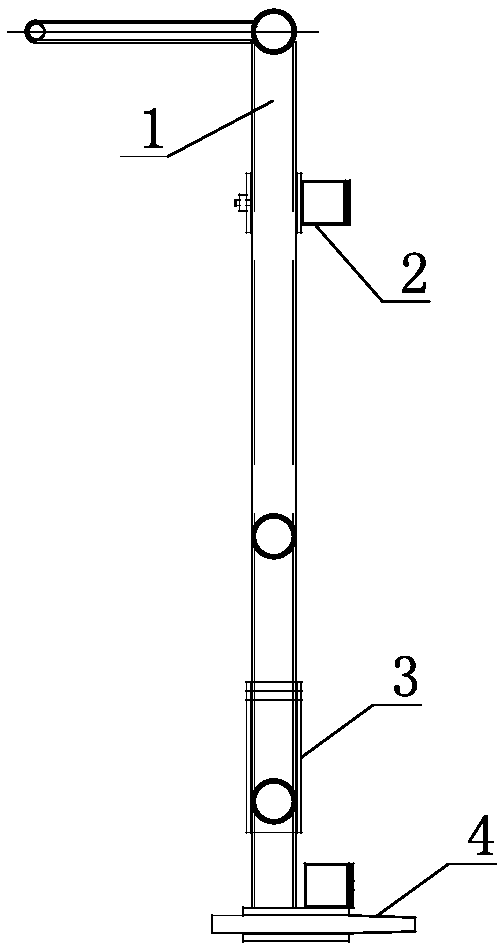

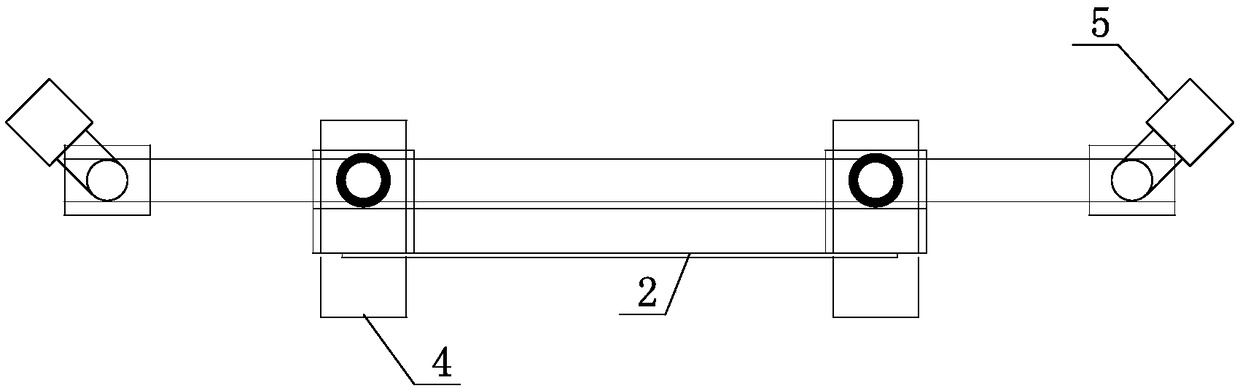

[0032] Such as Figure 1 to Figure 7 As shown, the high and low voltage panel transport and installation vehicle of the present invention includes a frame 1, iron forks 4 are respectively arranged at the bottom of both ends of the frame 1, and a lifting device 3 is arranged on the vertical direction of the frame 1, and the lifting device 3 includes two The sleeves 12 are set on the side wall of the frame 1, the beams are arranged between the sleeves 12, the universal wheels 5 are respectively arranged at the bottom of both ends of the beams, the support plates 11 are respectively arranged above the two ends of the beams, and the support plates 11 are respectively fixed on the sleeves 12 On the inner side, an eccentric pressing assembly is arranged above the support plate 11, and the eccentric pressing assembly is fixed on the inner side of the frame 1, and fixing devices 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com