Adhesive special for gypsum blocks and use method thereof

A technology of gypsum blocks and adhesives, applied in the field of building materials, which can solve the problems of short initial setting time, easy cake formation, long final setting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

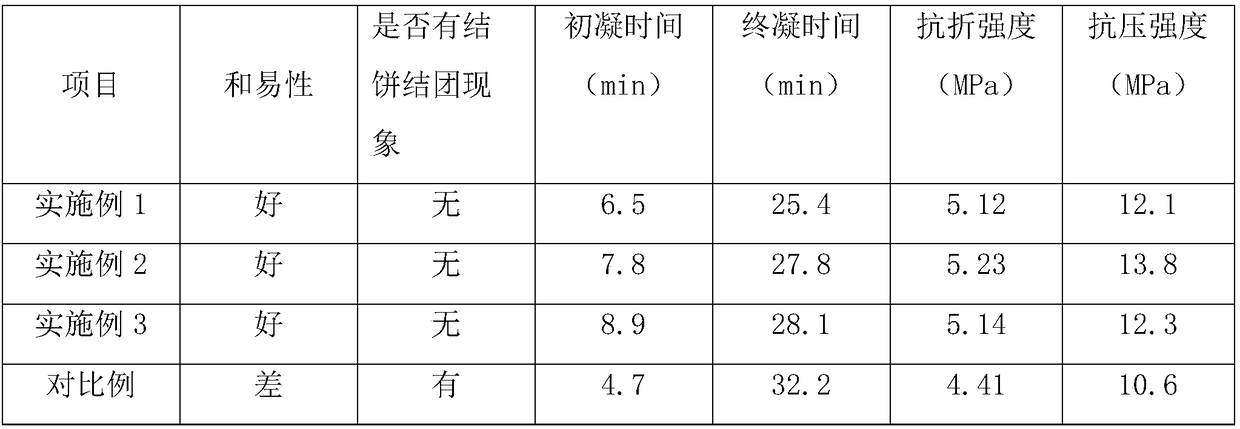

Examples

Embodiment 1

[0017] Adhesive for gypsum blocks, the mass percentages of each component are: 91kg of building gypsum powder, 7kg of 42.5MPa white cement, 0.3kg of protein retarder, 0.7kg of high-efficiency water reducer, 0.1kg of thixotropic agent, 0.4kg of emulsified fat powder, 0.1kg of wood fiber, and 0.4kg of vegetable glue.

[0018] Among them, protein retarder, high-efficiency water reducer, thixotropic agent, emulsified fat powder, wood fiber, and vegetable glue are all common and easy-to-buy product types in the market, and this application does not make specific limitations.

[0019] The method of using the special adhesive for gypsum blocks is as follows: put each component into the mixer according to the mass, dry mix for 10 minutes at normal temperature and pressure, and then sieve through a 100-mesh sieve until the residue is less than 1 % of the mass, remove the residue after sieving, and the other components mixed together are the adhesive, then add the adhesive to the mixer ...

Embodiment 2

[0021] The difference between this example and Example 1 is that the mass percentages of each component are: 93kg of building gypsum powder, 5kg of 42.5MPa white cement, 0.5kg of protein retarder, 0.5kg of superplasticizer, and thixotropic agent 0.2kg, emulsified fat powder 0.3kg, wood fiber 0.2kg, vegetable glue 0.3kg.

Embodiment 3

[0023] The difference between this example and Example 1 is that the mass percentages of each component are: 95kg of building gypsum powder, 3kg of 42.5MPa white cement, 0.7kg of protein retarder, 0.3kg of superplasticizer, and thixotropic agent 0.3kg, emulsified fat powder 0.2kg, wood fiber 0.3kg, vegetable glue 0.2kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com