Degradable polyethylene plastic and preparation method thereof

A polyethylene plastic and polyethylene technology, applied in the field of degradable polyethylene plastic and its preparation, can solve the problems of insufficient environmental protection, long degradation time, etc., and achieve the effect of easy availability of raw materials and environmental protection, simple preparation process, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

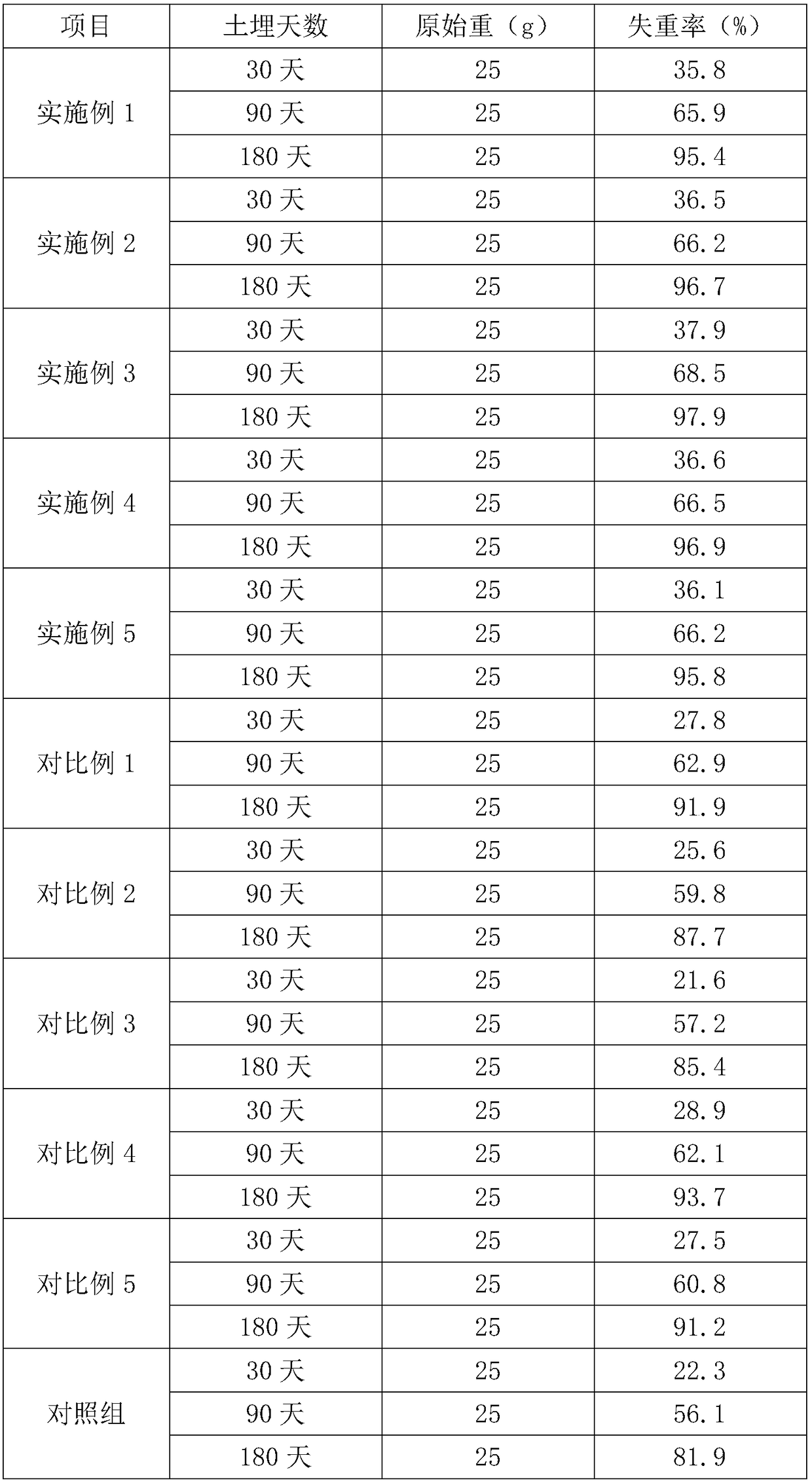

Examples

Embodiment 1

[0021] A degradable polyethylene plastic includes the following raw materials in parts by weight: 65 parts of polyethylene, 10 parts of Mikania micrantha extract, 8 parts of bentonite, 5 parts of Golden Dragon, and 1 part of zirconocene dichloride.

[0022] The preparation method of the Mikania micrantha extract is: taking Mikania micrantha with 20% lye as a solvent, soaking at 40-60°C for 2 hours, and filtering to obtain the extract; bleaching the extract at a bleaching temperature of 60°C , The bleaching time is 40 minutes; after bleaching, it is eluted with a 15% ethanol solution to a pH of 7, and dried to obtain an extract of Mikania micrantha.

[0023] A preparation method of degradable polyethylene plastic includes the following steps:

[0024] (1) Mix the extract of Mikania micrantha and Golden Dragon at 90°C and mix and stir for 15 minutes, mix the resultant with bentonite, and stir at 45°C for 30 minutes;

[0025] (2) Mix polyethylene and zirconocene dichloride, mix and stir ...

Embodiment 2

[0028] A degradable polyethylene plastic includes the following raw materials in parts by weight: 68 parts by weight of polyethylene, 14 parts of Mikania micrantha extract, 10 parts of bentonite, 6 parts of Golden Dragon, and 2 parts of zirconocene dichloride.

[0029] The preparation method of the Mikania micrantha extract is: take Mikania micrantha with 25% lye as a solvent, soak for 2.5 hours at 45°C, and filter to obtain the extract; bleach the extract at a bleaching temperature of 62°C and bleach The time is 45 minutes; after bleaching treatment, it is eluted with an ethanol solution with a mass fraction of 18% to a pH of 7, and dried to obtain an extract of Mikania micrantha.

[0030] A preparation method of degradable polyethylene plastic includes the following steps:

[0031] (1) Mix the extract of Mikania micrantha with Golden Dragon, and mix and stir for 18 min at 92°C, mix the resultant with bentonite, and stir for 38 min at 48°C;

[0032] (2) Mix polyethylene and zirconoce...

Embodiment 3

[0035] A degradable polyethylene plastic includes the following raw materials in parts by weight: 70 parts of polyethylene, 16 parts of Mikania micrantha extract, 12 parts of bentonite, 7 parts of Golden Dragon, and 3 parts of zirconocene dichloride.

[0036] The preparation method of the Mikania micrantha extract is: taking Mikania micrantha with 30% lye as a solvent, soaking at 50°C for 3 hours, and filtering to obtain the extract; bleaching the extract at a bleaching temperature of 65°C and bleaching The time is 50min; after bleaching, it is eluted with a 20% ethanol solution to a pH of 7.2 and dried to obtain an extract of Mikania micrantha.

[0037] A preparation method of degradable polyethylene plastic includes the following steps:

[0038] (1) Mix the extract of Mikania micrantha with Golden Dragon, and mix and stir at 93°C for 25 minutes, and mix the resultant with bentonite, and stir for 50 minutes at 50°C;

[0039] (2) Mix polyethylene and zirconocene dichloride, mix and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com