High-strength low-temperature resistant material for turnover box

A turnover box and high-strength technology, applied in the field of polymer materials, can solve the problems of cracking of parts, inability to effectively transfer and diffuse internal stress and external destructive force, and single function of turnover box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

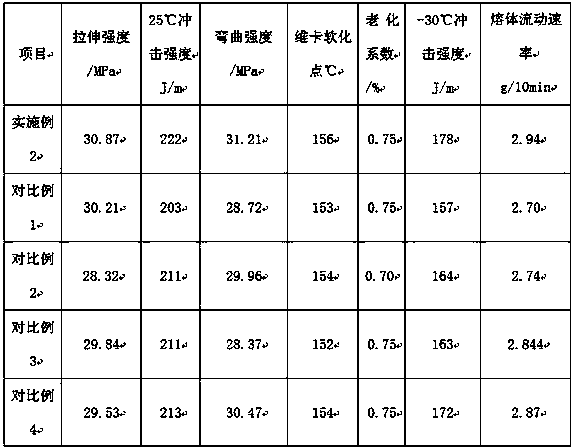

Examples

Embodiment 1

[0021] A high-strength low-temperature-resistant material for a turnover box, comprising the following components in parts by weight: 123 parts of polypropylene, 61 parts of high-density polyethylene, 23 parts of SEBS, 8 parts of aluminum oxide, 11 parts of aluminum-doped zinc oxide whiskers, 14 parts of hollow glass microspheres, 15 parts of nano-attapulgite, 11 parts of organically modified montmorillonite, 13 parts of wollastonite powder, 2 parts of antioxidant, 2 parts of compatibilizer, 3 parts of naphthenic oil, and 2 parts of EBS.

[0022] A high-strength low-temperature-resistant material for a turnover box, the preparation method of which comprises the following steps:

[0023] Step 1: Weigh each raw material in parts by weight, put polypropylene, high-density polyethylene, SEBS, and naphthenic oil into a high-speed mixer, heat to 30°C, and stir for 30 minutes at a speed of 500 rpm;

[0024] Step 2: Then add alumina, aluminum-doped zinc oxide whiskers, hollow glass mi...

Embodiment 2

[0032] A high-strength low-temperature-resistant material for a turnover box, comprising the following components in parts by weight: 121 parts of polypropylene, 67 parts of high-density polyethylene, 24 parts of SEBS, 9 parts of aluminum oxide, 11 parts of aluminum-doped zinc oxide whiskers, 15 parts of hollow glass microspheres, 17 parts of nano-attapulgite, 11 parts of organically modified montmorillonite, 13 parts of wollastonite powder, 2 parts of antioxidant, 2 parts of compatibilizer, 3 parts of naphthenic oil, and 2 parts of EBS.

[0033] A high-strength low-temperature-resistant material for a turnover box, the preparation method of which comprises the following steps:

[0034] Step 1: Weigh each raw material by parts by weight, put polypropylene, high-density polyethylene, SEBS, and naphthenic oil into a high-speed mixer, heat to 60°C, and stir for 30 minutes at a speed of 500 rpm;

[0035] Step 2: Then add alumina, aluminum-doped zinc oxide whiskers, hollow glass mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com