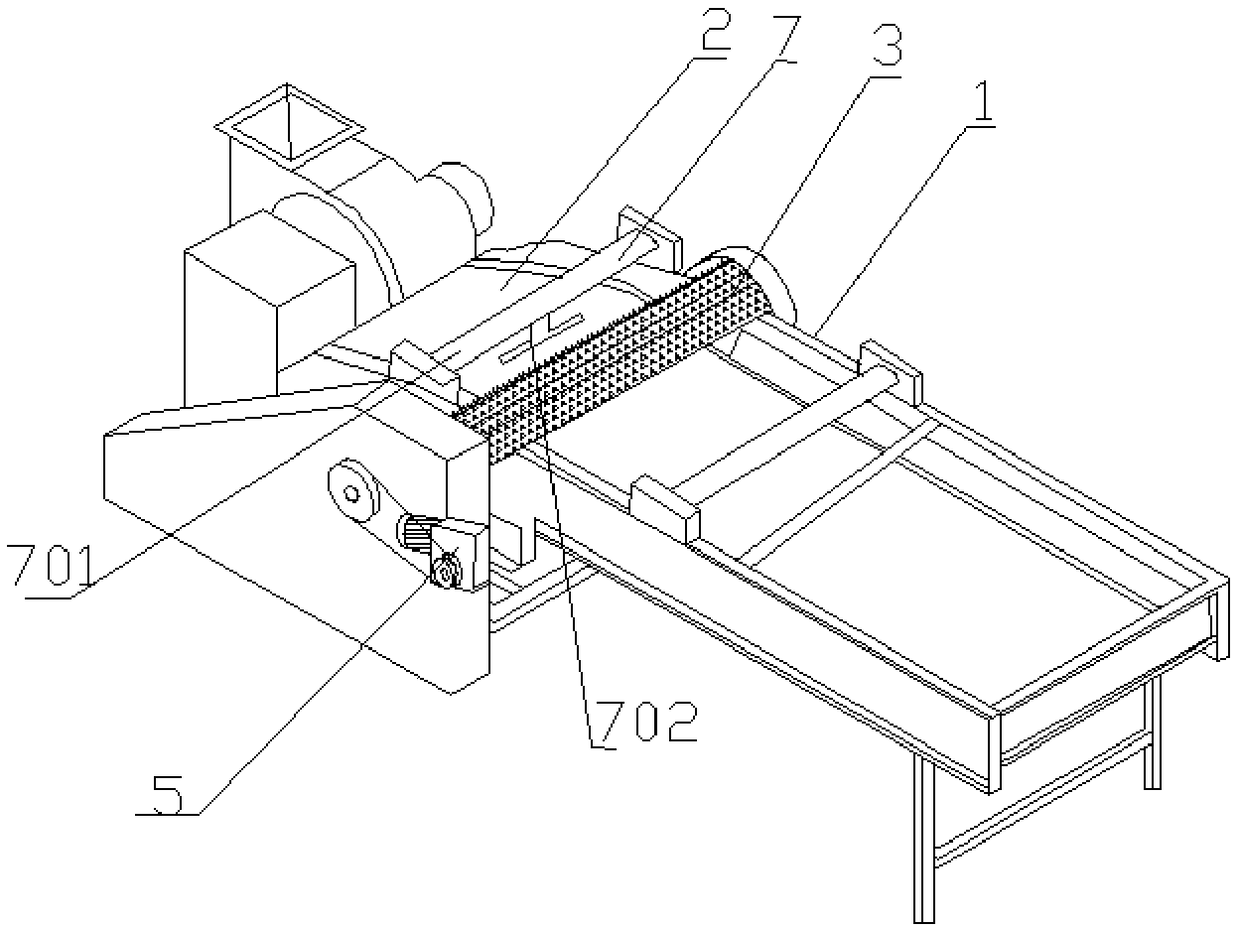

Automatic fine-tuning control device for roller spacing bearded needle relative positions

An automatic fine-tuning, relative position technology, applied in the direction of opening and cleaning with toothed tools, fiber opening and cleaning machines, etc., can solve the problems of affecting the uniformity of cotton web, uneven fiber opening, insufficient fiber fluff, etc. High working efficiency, good fiber bulkiness and good opening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0041] In practical application, the user weighs the fiber raw materials of various components according to the ratio, and first performs preliminary loosening to loosen the large fiber clusters, and at the same time, the fibers of various components in the raw materials are uniformly mixed, and the fiber raw materials are The fine opening is carried out by the opener, and the fibers are further loosened. The raw material fibers are transported through the conveying components. When the monitoring sensor 701 detects that the transported fiber raw materials have unbalanced feeding and accumulation, the feeder 702 replenishes the fiber raw materials. , wherein, the feeder is a vacuum suction device, and the vacuum suction device absorbs the raw material fibers at the positions where the raw material fibers are excessively accumulated to the positions where the raw material fibers are sparse.

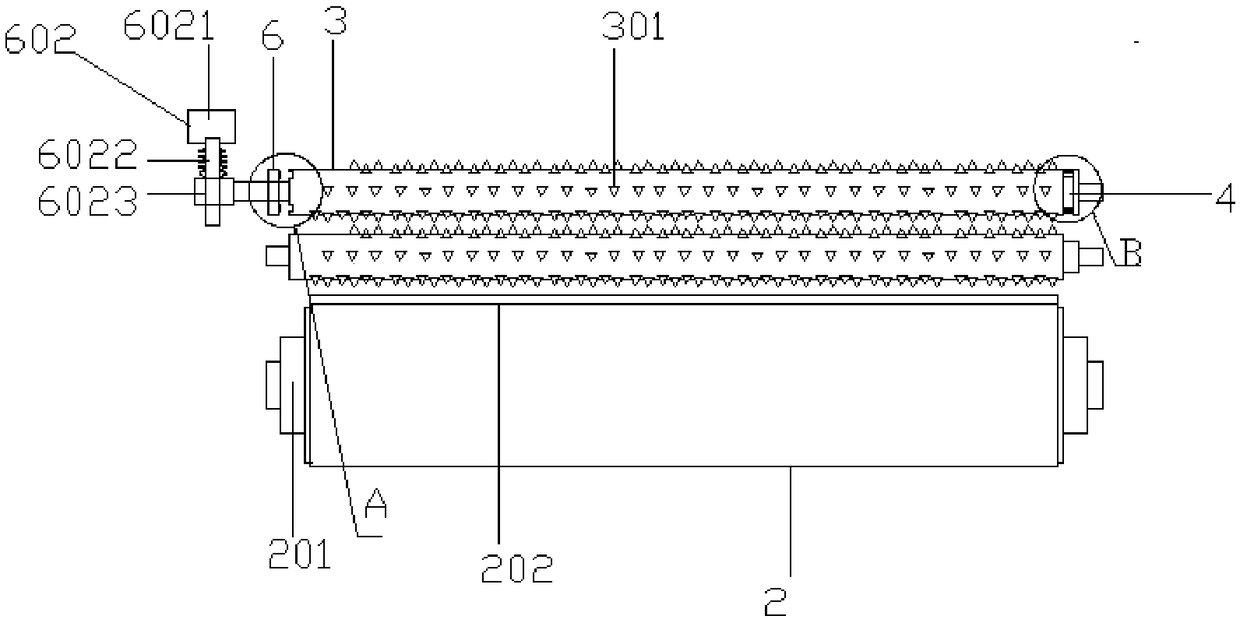

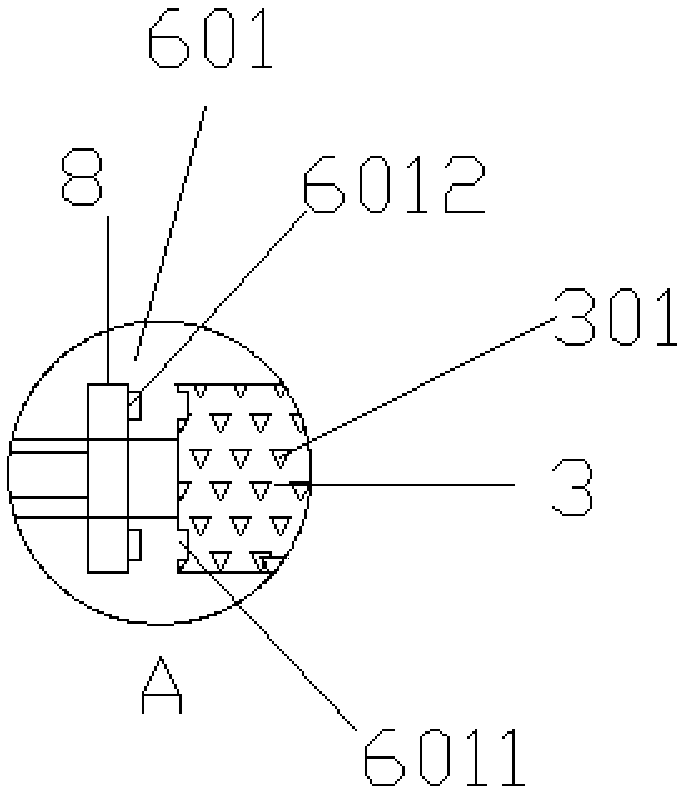

[0042] The claw roller 3 roller spacing is fine-tuned left and right, because the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com