Space yarn guide bar swinging type electronic shogging device of extra large-gauge warp knitting machine

A technology of traversing device and spacer yarn, which is applied in the field of warp knitting machines, and can solve problems such as the inability of yarns to form loops, inaccurate needle movement of yarn needles, damage to latch needles or yarn guide needles, etc., to achieve easy function and horizontal movement High displacement accuracy, reducing the effect of missed stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

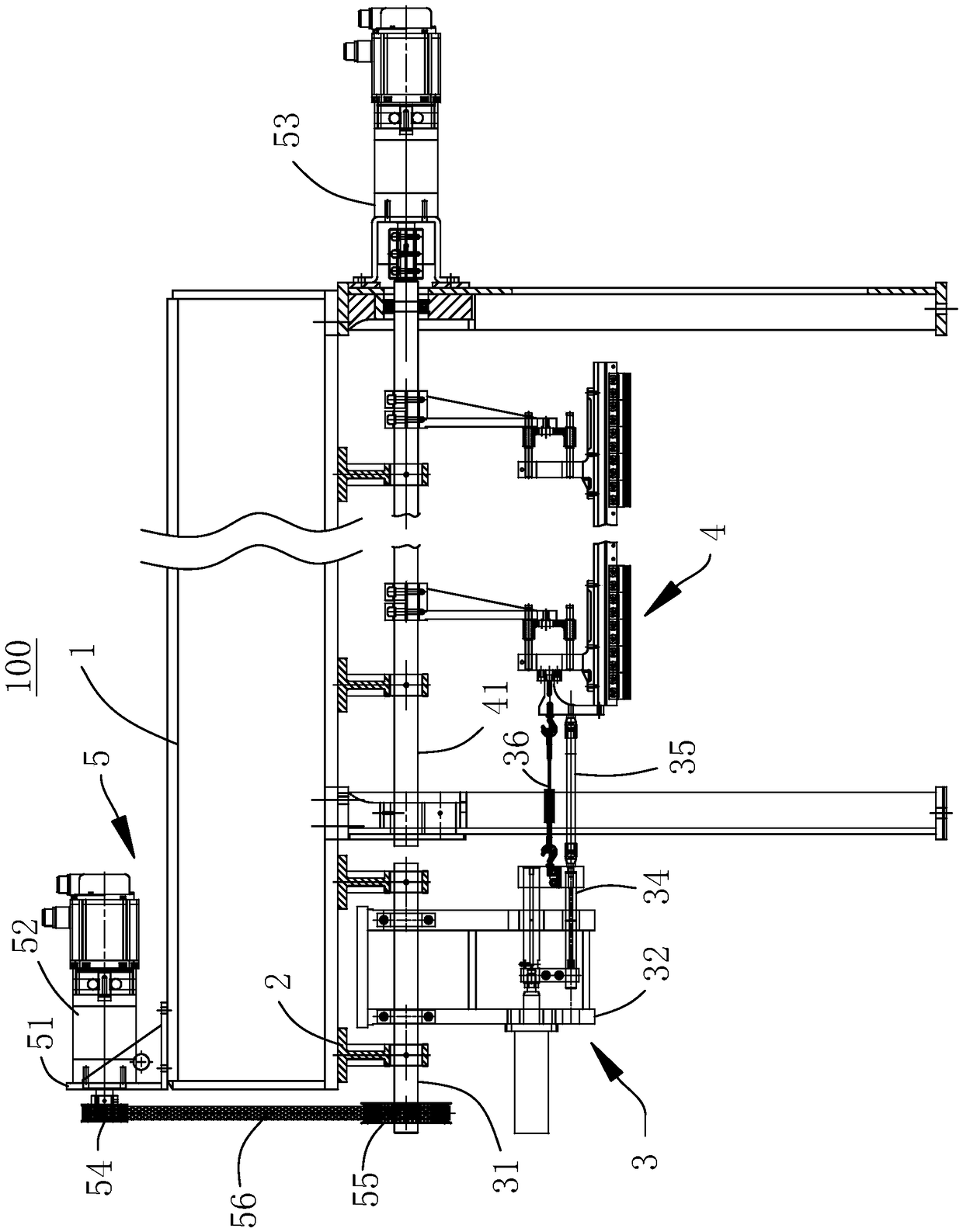

[0036] Please refer to figure 1 , the present embodiment provides a spacer bar swing electronic traverse device 100 for an ultra-large gauge warp knitting machine, including a beam 1, a plurality of swing shaft seats 2, a traverse mechanism 3, a bar connection mechanism 4 and a servo drive Component 5.

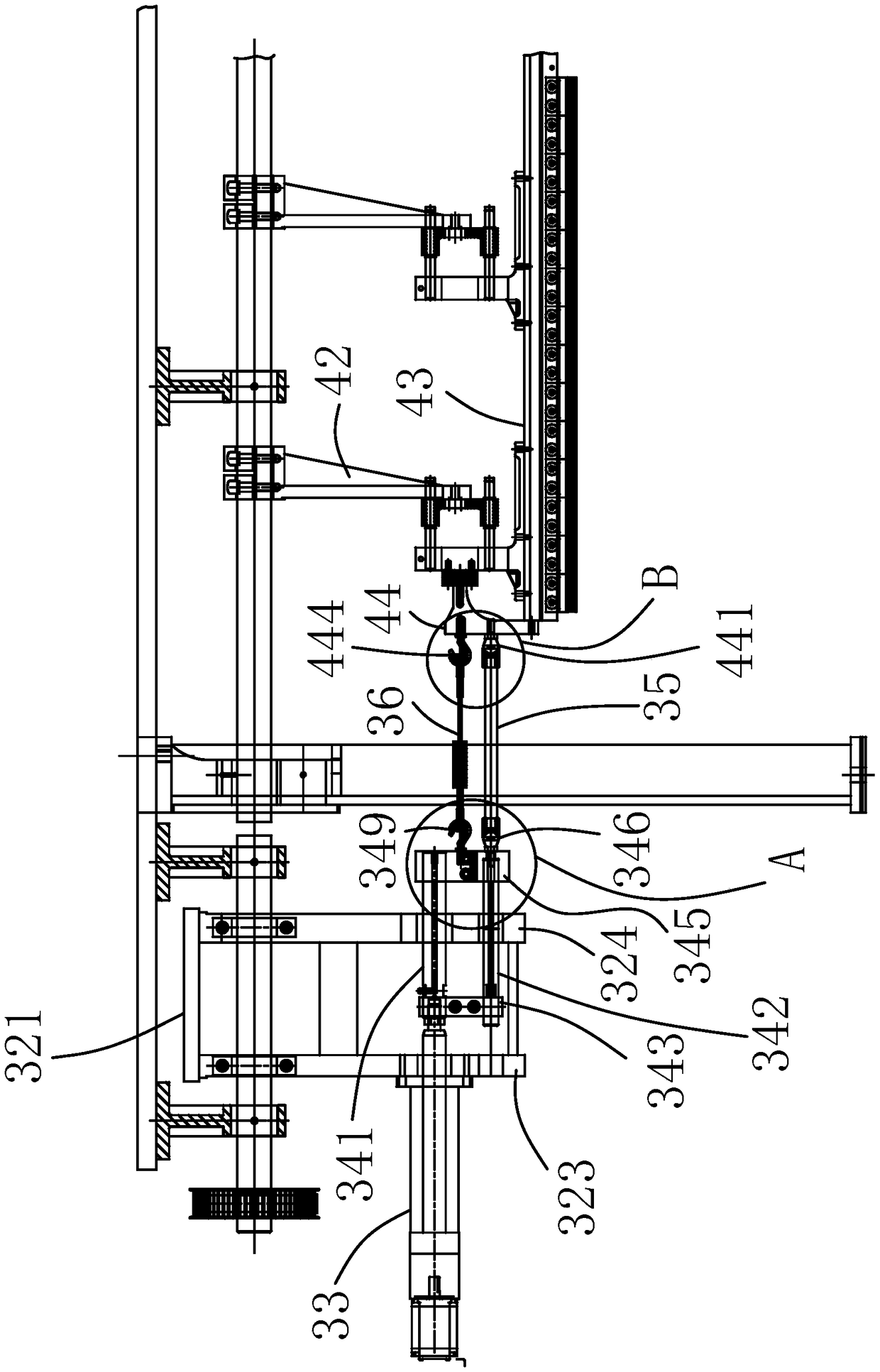

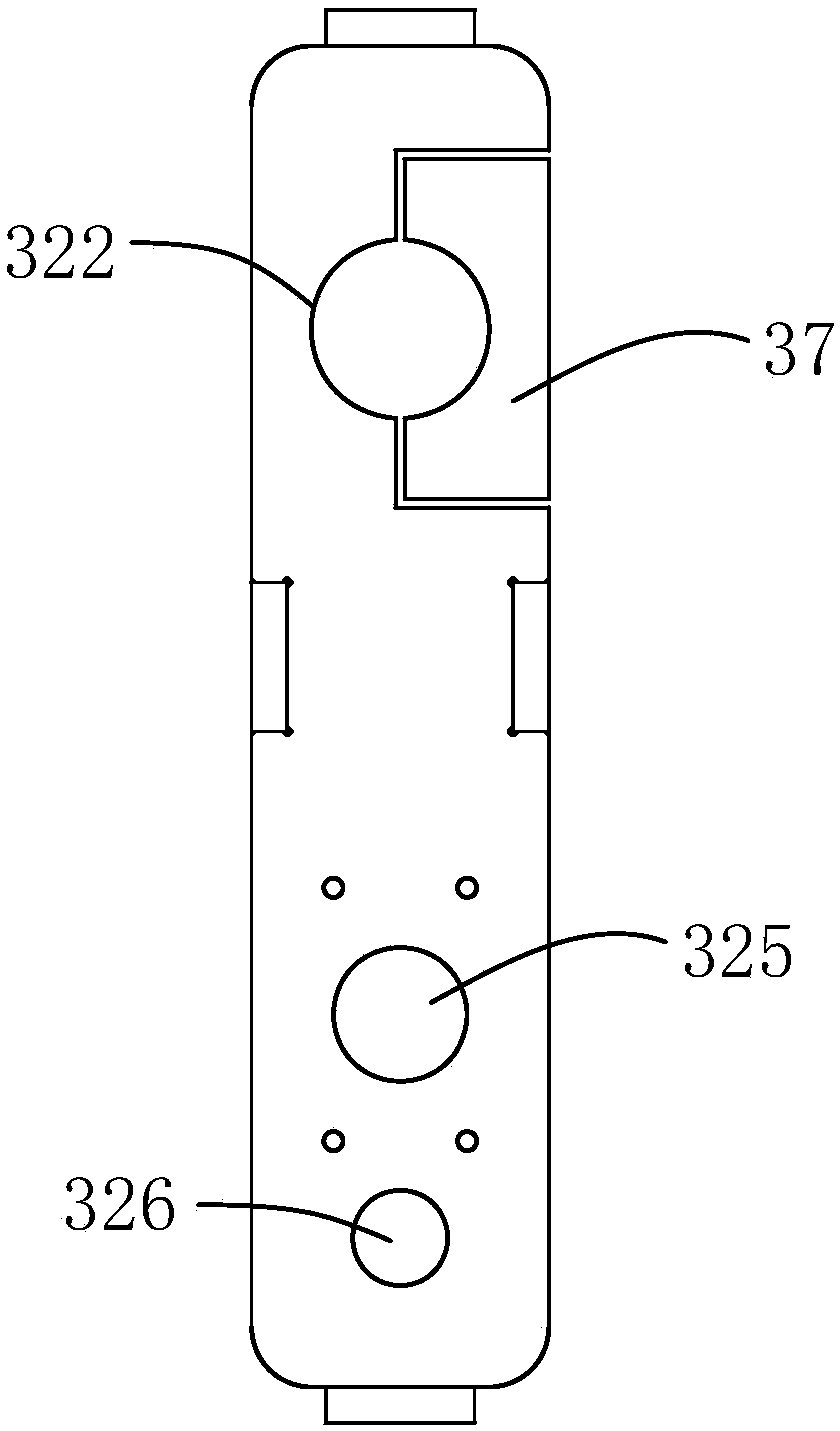

[0037] In this embodiment, a plurality of balance shaft seats 2 are arranged on the lower end of the cross beam 1 at intervals along the length direction of the cross beam 1, and are connected with the cross beam 1; The pendulum shaft 31, the traversing seat 32 sleeved on the traversing pendulum shaft 31 and connected to the traversing pendulum shaft 31 in transmission, the electric cylinder 33 equipped with a traversing servo motor, and the traversing seat 32 slidably connected The transmission assembly 34, the ejector rod assembly 35 and the tension spring assembly 36 connected with the transmission assembly 34, the traversing balance shaft 31 is arranged along the length d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com