Wear-resistant aid for textiles and preparation method thereof

A wear-resistant additive and textile technology, which is used in textiles and papermaking, wear-resistant fibers, fiber processing, etc. Mechanical strength and wear resistance, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

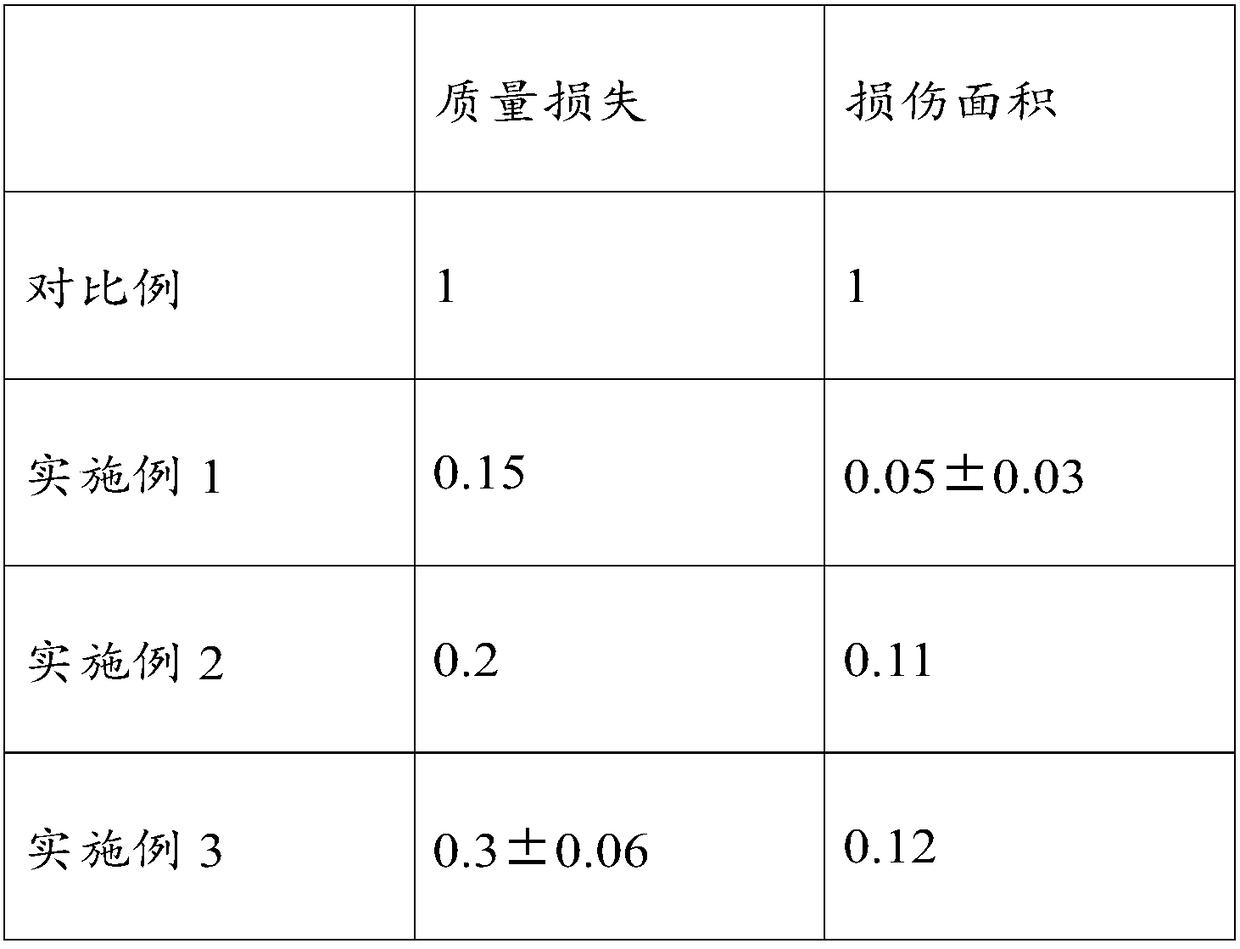

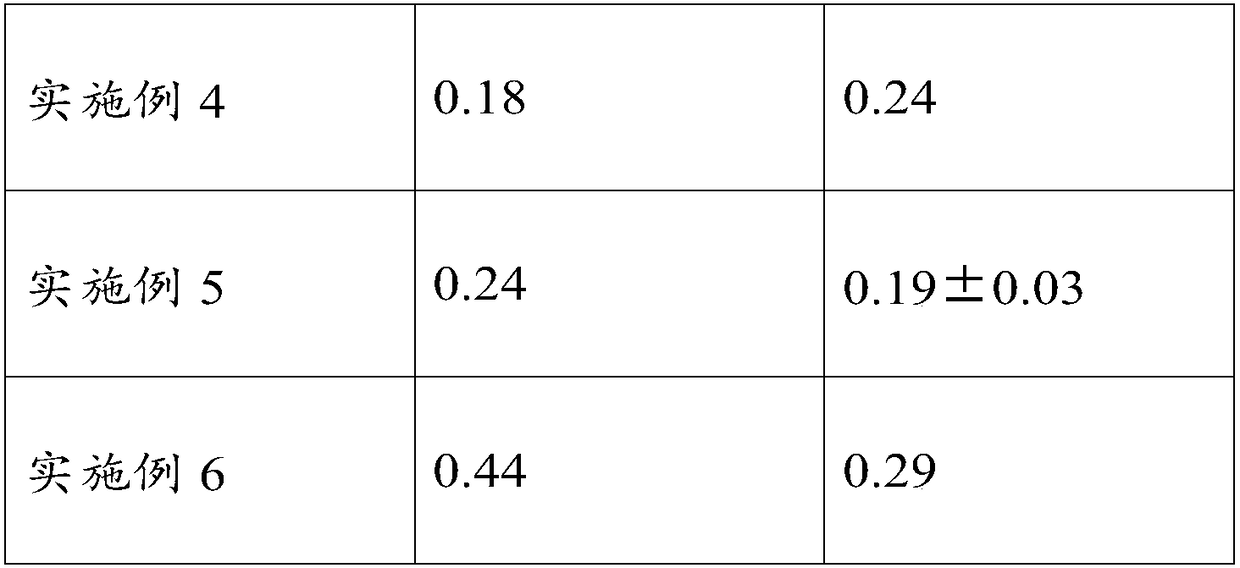

Examples

preparation example Construction

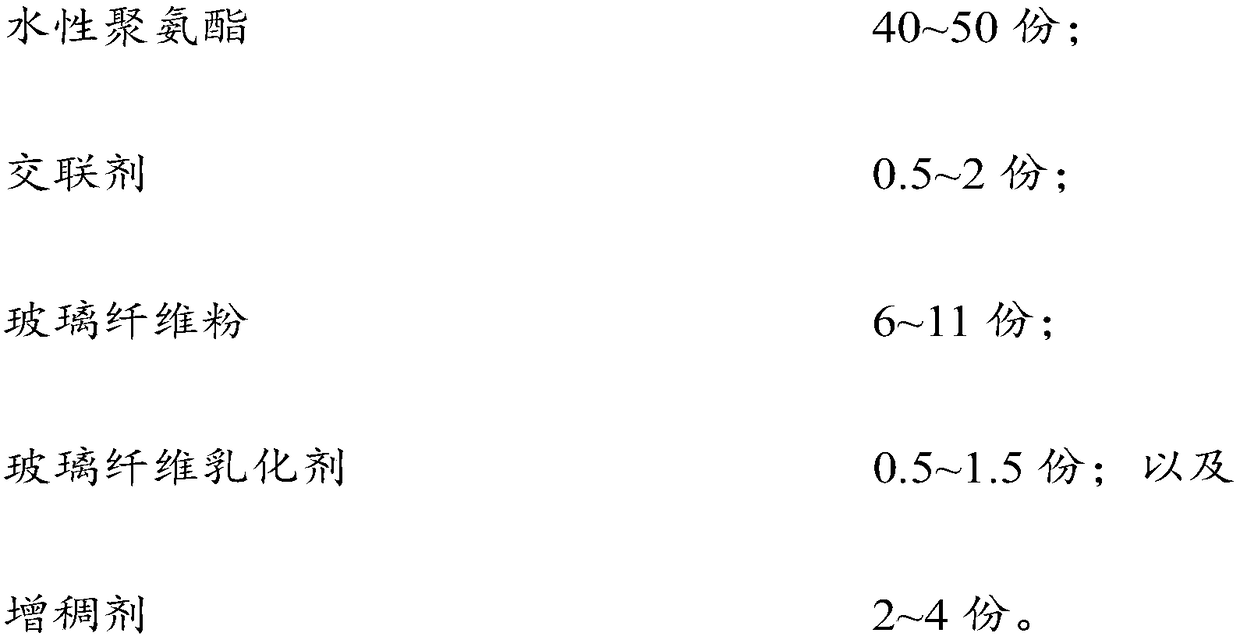

[0033] And the preparation method of the anti-wear additive provided by the embodiment of the present invention, it comprises:

[0034] The glass fiber is ground to obtain a primary powder.

[0035] The primary powder is screened on an ultrasonic vibrating sieve. The ultrasonic vibrating sieve is continuously equipped with 3 layers of 400-mesh screens, and each screen is placed with a number of steel balls with a diameter of 1-5mm. The secondary powder is screened through 3 layers of screens. body.

[0036] Add the secondary powder and several ceramic beads with a diameter of 3 to 5 mm into water and stir for 15 to 30 minutes at a stirring rate of 15 to 25 r / min, filter the ceramic beads and then suction filter to obtain glass fiber powder.

[0037] Add glass fiber powder and glass fiber emulsifier to water-based polyurethane and stir for 20-30 minutes at a stirring rate of 100-120 r / min. Then add all other raw materials except the cross-linking agent and stir for 20-30 minu...

Embodiment 1

[0053] This embodiment provides a kind of wear-resisting auxiliary agent for textiles, and its raw materials include by weight: 50 parts of water-based polyurethane, 1.5 parts of crosslinking agent, 7.5 parts of glass fiber powder, 1.2 parts of glass fiber emulsifier, 3.5 parts of Thickener, 17 parts of acrylic resin, and 5.5 parts of feel modifier.

[0054] This anti-wear additive is made by following method:

[0055] The glass fiber is ground to obtain a primary powder.

[0056] The primary powder is screened on an ultrasonic vibrating sieve to obtain the secondary powder. Wherein, the diameter of the steel ball placed on the uppermost screen is 5mm, and the diameter of the steel ball placed on the middle screen is 3mm. The diameter of the steel ball placed on the bottom sieve is 1mm.

[0057] Add the secondary powder and ceramic beads with a diameter of 3 mm into water and stir for 20 minutes at a stirring rate of 20 r / min. Filter the ceramic beads and then filter with s...

Embodiment 2

[0060] This embodiment provides a kind of wear-resisting auxiliary agent for textiles, its raw material includes by weight: 48 parts of water-based polyurethane, 1.8 parts of crosslinking agent, 9 parts of glass fiber powder, 0.8 part of glass fiber emulsifier, 2.5 parts of Thickener, 15 parts of acrylic resin, and 8.5 parts of feel modifier.

[0061] This anti-wear additive is made by following method:

[0062] The glass fiber is ground to obtain a primary powder.

[0063] The primary powder is screened on an ultrasonic vibrating sieve to obtain the secondary powder. Wherein, the diameter of the steel ball placed on the uppermost screen is 4mm, and the diameter of the steel ball placed on the middle screen is 2mm. The diameter of the steel balls placed on the bottom sieve is 1.5 mm.

[0064] Add the secondary powder and ceramic beads with a diameter of 5 mm into water and stir for 15 minutes at a stirring rate of 15 r / min. Filter the ceramic beads and then filter with suct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com