Modified inorganic nano-particle as well as preparation method and use thereof

A technology for modifying inorganic nanoparticles, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of non-uniform dispersion of inorganic particles and poor compatibility, and achieve good industrial application prospects, low cost, and high efficiency. The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the preparation of modified nano-calcium carbonate particles

[0021] Take 2.7g of stearyl alcohol and add it to the reaction kettle, raise the temperature to 80°C to remove water by vacuuming, add 200ml of toluene and 2.5g of MDI in sequence, raise the temperature to 90°C, stir the reaction at high speed for 4 hours under the protection of nitrogen, then add 300ml of toluene and 100g of Dry nano-calcium carbonate, the average particle size of calcium carbonate is 100nm, continue to react for 4 hours, vacuum filter after the reaction, wash with toluene, dry, pulverize, and sieve to obtain modified nano-calcium carbonate particles.

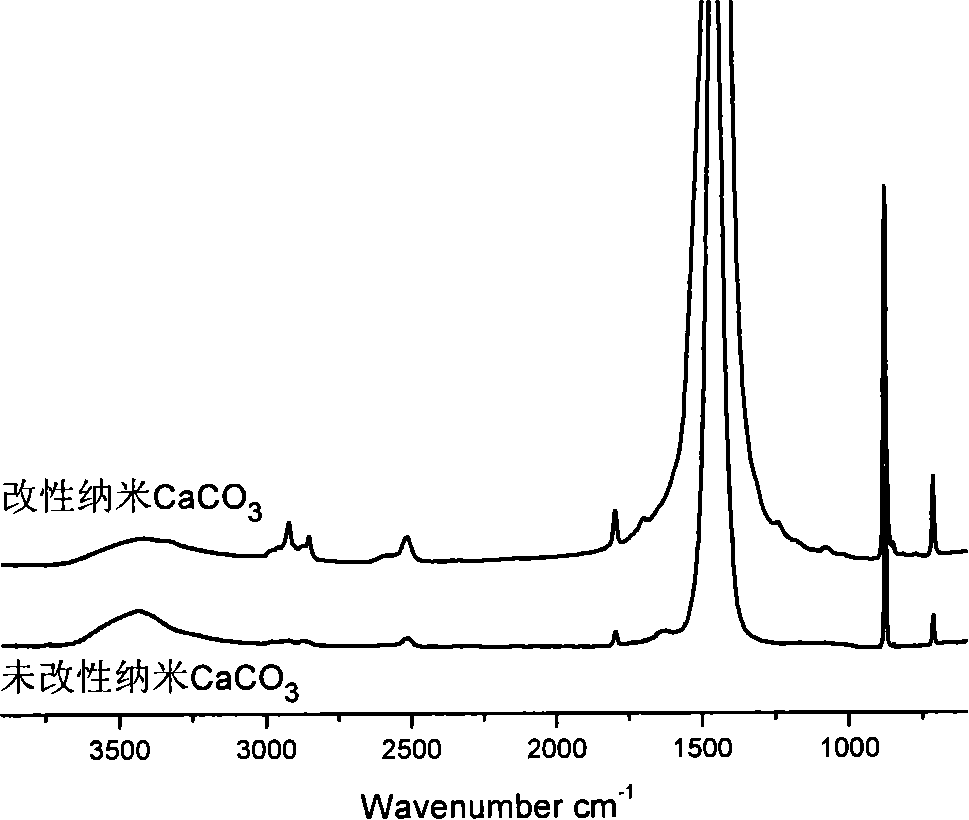

[0022] Depend on figure 1 Infrared spectrum detection shows that, according to the modified nano-calcium carbonate particle prepared by the above-mentioned method, at 2900cm -1 There are stretching vibration absorption peaks of methylene on the left and right, at 2240cm -1 There are no absorption peaks of isocyanate groups on...

Embodiment 2

[0023] Embodiment 2, the preparation of modified nano silica particles

[0024] Take 2.7g of stearyl alcohol and add it to the reaction kettle, raise the temperature to 80°C to remove water by vacuuming, add 200ml of toluene and 2.5g of MDI in sequence, raise the temperature to 85°C, stir and react at high speed under nitrogen protection for 5h, then add 800ml of toluene and 50g of Dry nano-silica, the average particle size of the silica is 50nm, continue to react for 5 hours, vacuum filter after the reaction, wash with toluene, dry, pulverize, and sieve to obtain modified nano-silica particles.

Embodiment 3

[0025] Embodiment 3, the preparation of modified nano silica particles

[0026] Take 2.42g of cetyl alcohol and add it to the reaction kettle, raise the temperature to 80°C to remove water by vacuuming, add 200ml of toluene and 1.74g of TDI in turn, raise the temperature to 90°C, stir the reaction at high speed for 4 hours under the protection of nitrogen, then add 800ml of toluene and 50g of Dried nano silicon dioxide, the average particle size of silicon dioxide is 25nm, continue to react for 4 hours, vacuum filter after the reaction, wash with toluene, dry, pulverize, and sieve to obtain modified nano silicon dioxide particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com