High-efficiency pulling-out device for underwater steel pipe piles

A steel pipe pile, high-efficiency technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, to achieve the effect of long effective working time, wide adaptability and construction safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

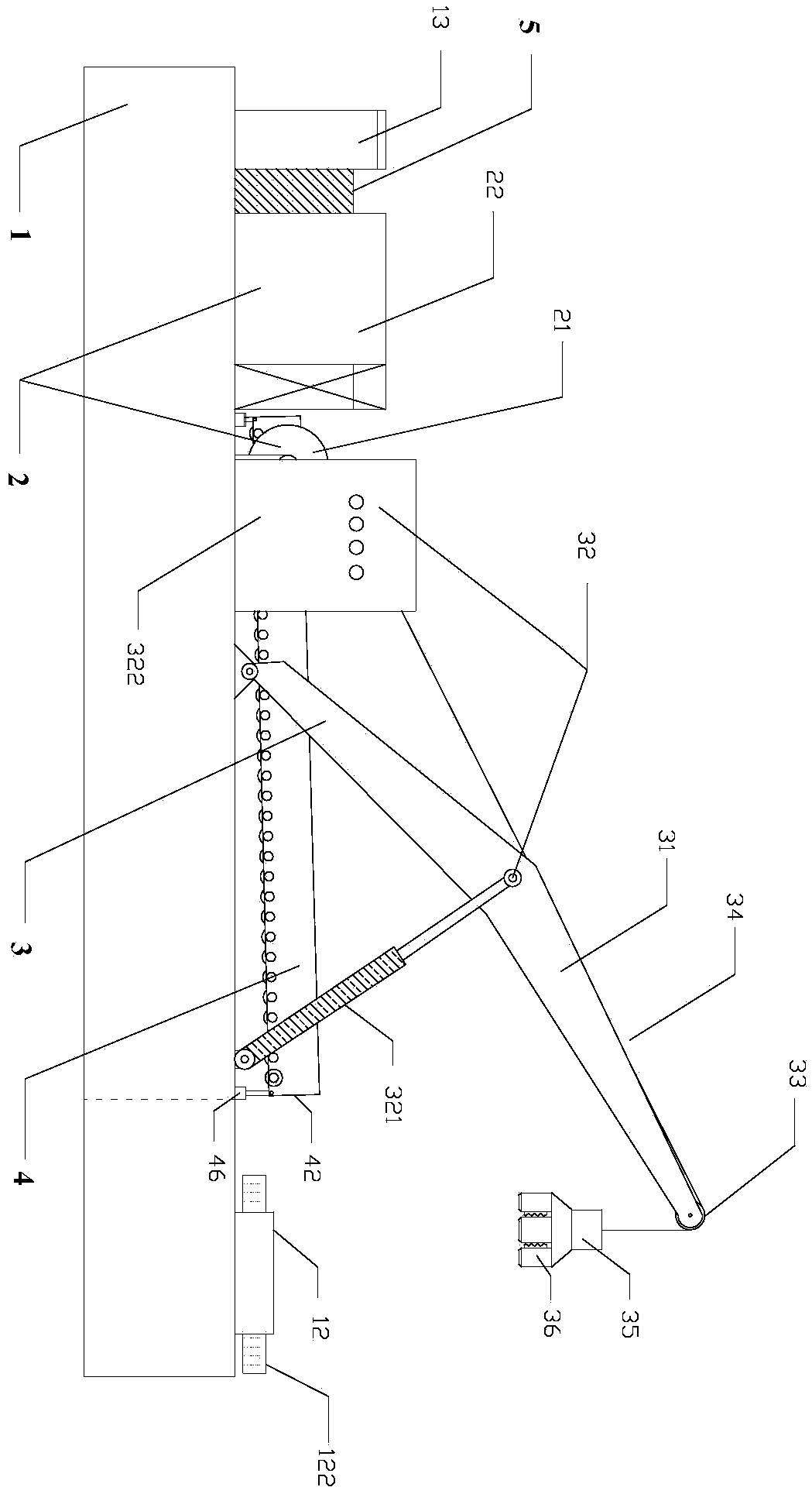

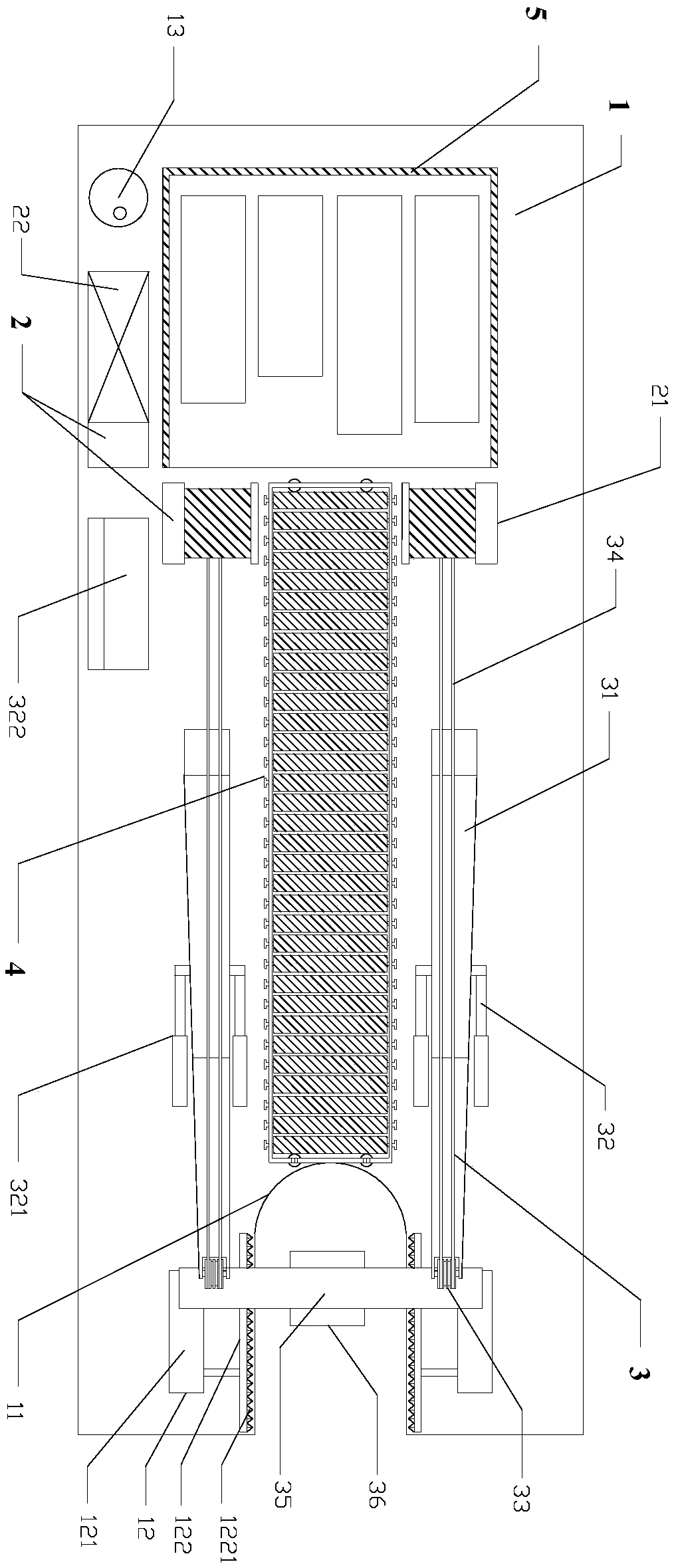

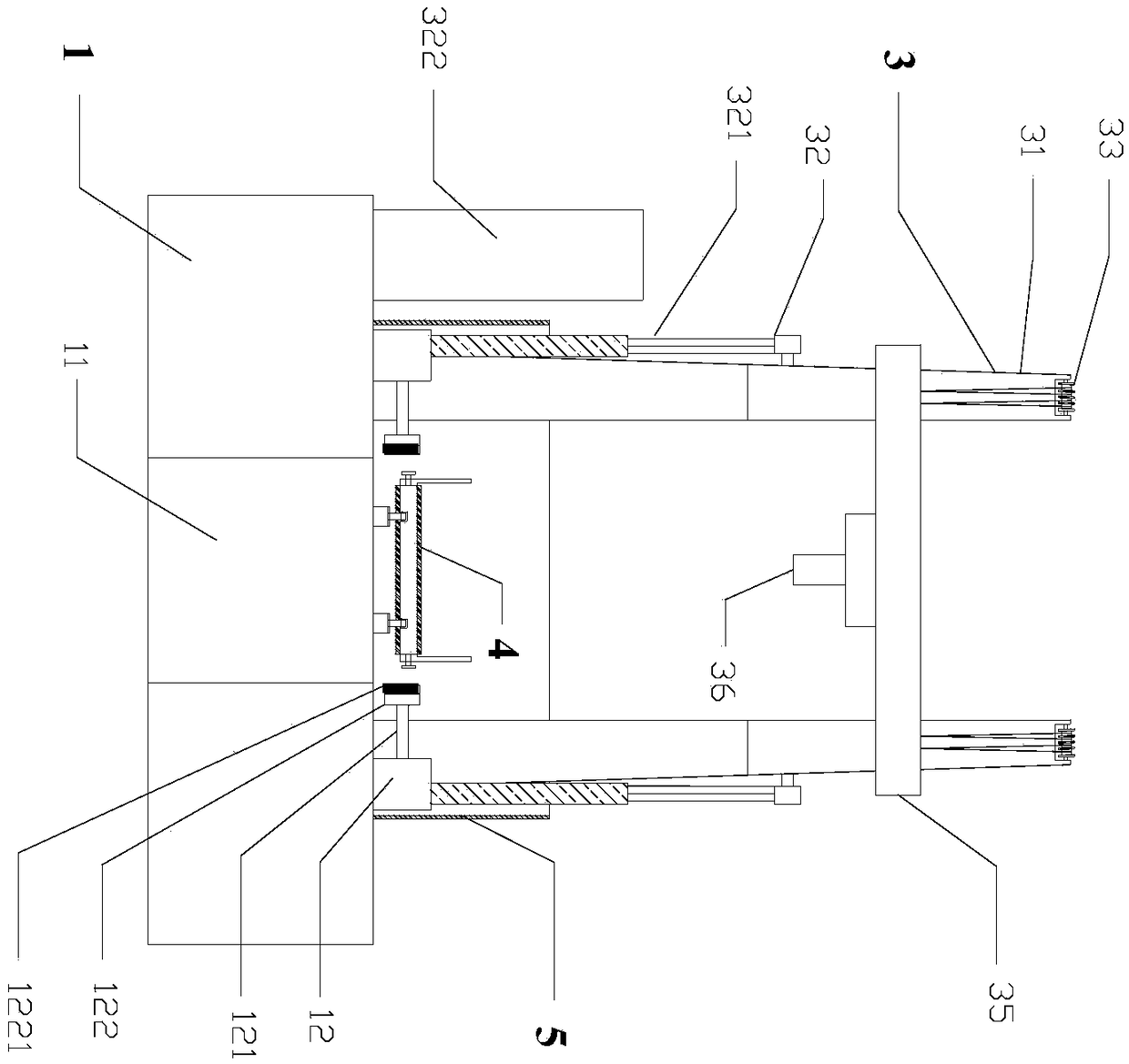

[0037] High-efficiency extraction device for underwater steel pipe piles, please refer to figure 1 , figure 2 , image 3 , including: a flat deck barge platform 1, a power system 2, and an extraction assembly 3; the head of the flat deck barge platform 1 is provided with a U-shaped groove 11; the power system 2 includes a hoist 21 arranged at the tail of the flat deck barge platform 1, which is 21 a diesel generator 22 for continuous power supply; the pulling assembly 3 includes a mechanical arm 31 whose bottom end is hingedly connected with the tail of the flat deck barge platform 1, and whose top end can swing up and down above the U-shaped groove 11, and a pulley block 33 arranged at the top of the mechanical arm 31, The hydraulic system 32 for swinging up and down of the mechanical arm 31, the steel wire rope 34, the vibratory hammer 35 that is hoisted on the top of the mechanical arm 31 through the pulley block 33 and the winch 21 by the steel wire rope 34, and the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com