Chemical loop power generation device based on casing pipe reactor

A technology of casing reactor and power generation device, which is applied in steam engine device, gas turbine device, machine/engine, etc., can solve the problems of single function of equipment or system, high equipment investment cost and operating cost, and improve utilization rate and save equipment. Cost and operating cost, good effect of feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

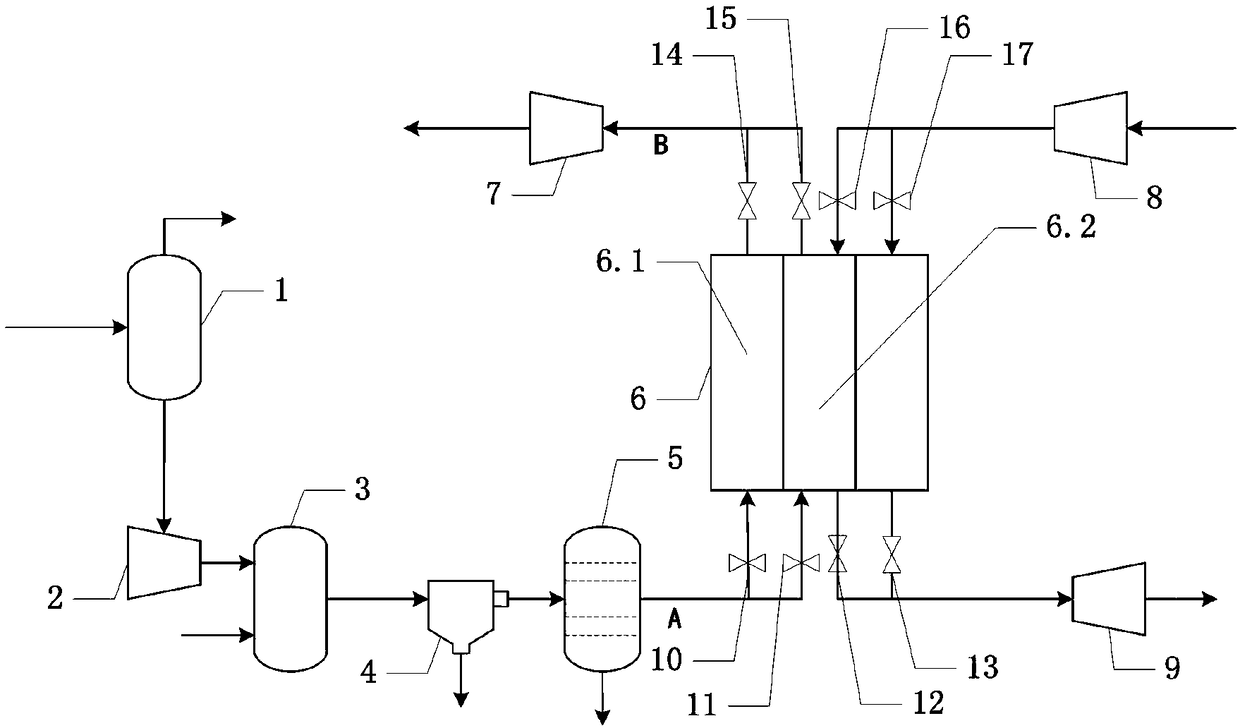

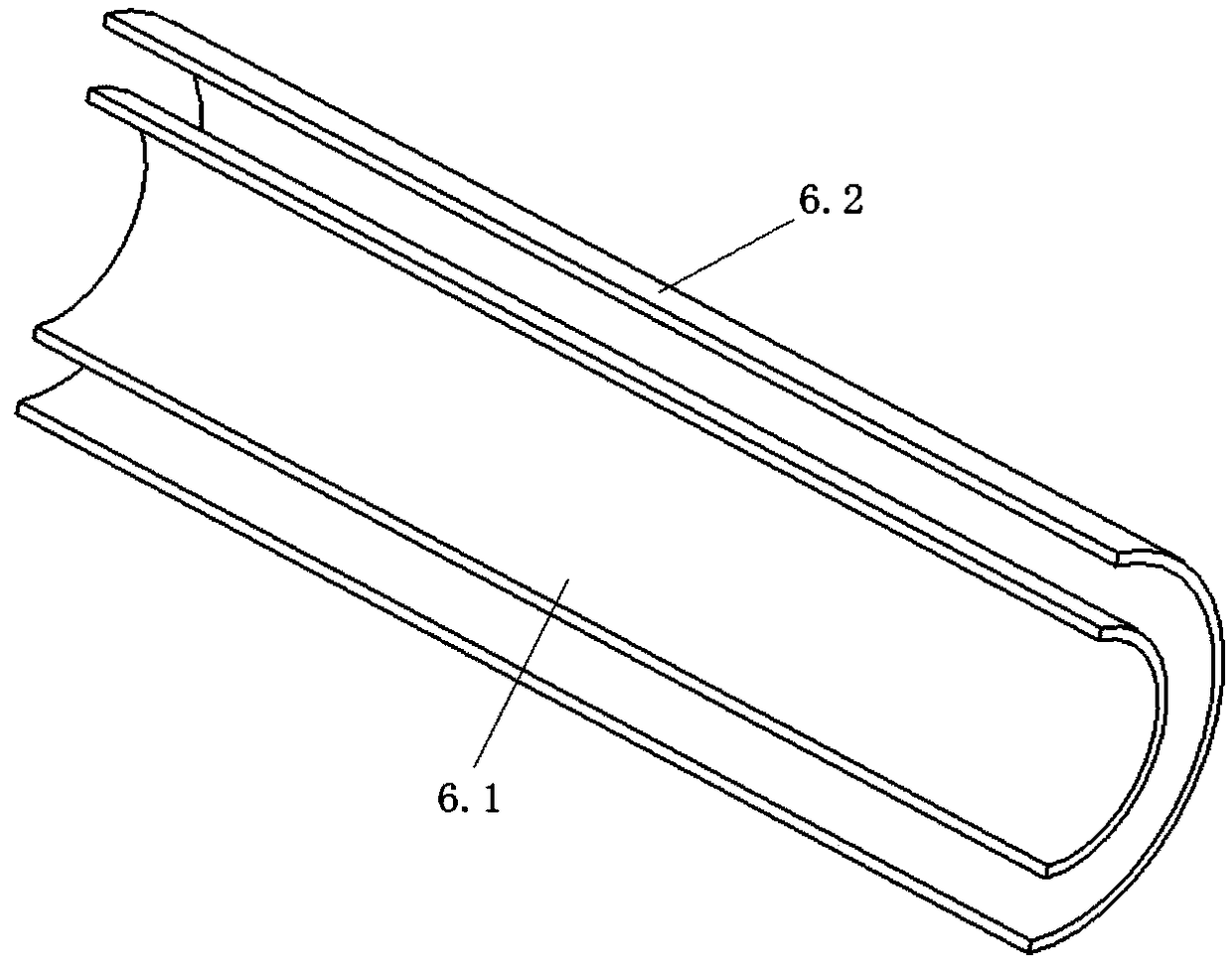

[0016] Such as figure 1 A chemical chain power generation device based on a casing reactor is shown, including an air separation machine 1, a first air compressor 2, a casing reactor 6, a first turbine 7, a second air compressor 8 and a second A turbine 9, the inlet of the air separator 1 is communicated with a fresh air source, the first outlet of the air separator 1 is communicated with a nitrogen pipeline, and the second outlet of the air separator 1 is communicated with the inlet of the first air compressor 2 through a pipeline , the outlet of the first air machine 2 communicates with the inlet of the sleeve reactor 6 through the pipeline A, the outlet of the sleeve reactor 6 communicates with the inlet of the first turbine 7 through the pipeline B, and the outlet of the first turbine 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com