A non-leakage and anti-clogging oil-cooled circulating high-efficiency synchronous intelligent self-priming pump

A cold cycle, anti-clogging technology, applied in the direction of non-variable pumps, pumps, pump components, etc., can solve the problems of slurry blocking the liquid storage chamber space, short service life, frequent maintenance, etc., to improve technical performance indicators , long service life and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

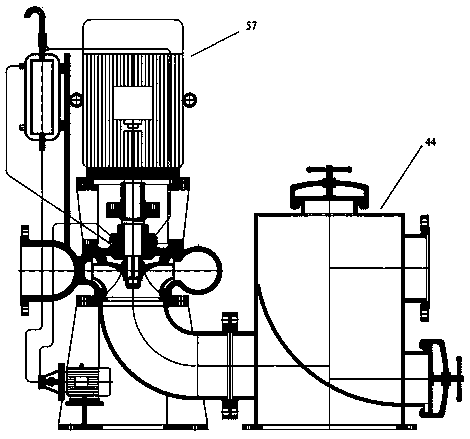

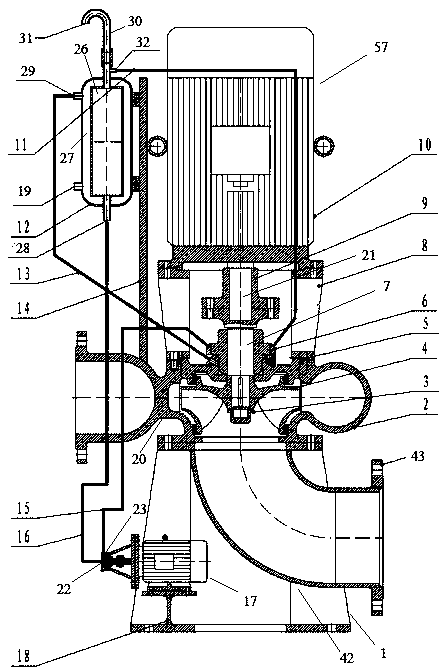

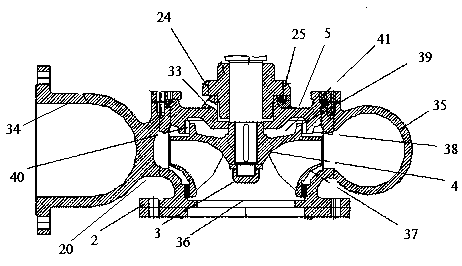

[0045] now attached Figures 1 to 4 The present invention is further described.

[0046] The present invention provides a CJB slurry non-leakage and anti-clogging oil-cooled circulation type high-efficiency synchronous intelligent self-priming pump, which includes a self-priming pump device 57 and a filtering device 44, and is characterized in that the self-priming pump device 57 includes a base 1, a pump Body 2 and motor 10, the base 1 includes a circulating pump bracket 18 and a circulating pump 17, the circulating pump bracket 18 is welded on the base 1, and the circulating pump 17 is fixed on the circulating pump On the bracket 18;

[0047] The pump body 2 includes a pump casing 20, a pump shaft 7, an impeller 4, a motor bracket 8, a cooling tank bracket 14 and a cooling tank 12; the upper part of the pump casing 20 is provided with an embedded pump cover 5; the pump shaft 7 is located at the central axis of the upper part of the pump cover 5, the impeller 4 is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com