A mechanical molecular spring unit body device and vibration isolator

A molecular spring, unit body technology, applied in liquid shock absorbers, springs/shock absorbers, springs, etc., can solve the problems of small static deformation, low natural frequency, etc., achieve small size, reduce overall size, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mechanical molecular spring unit body device

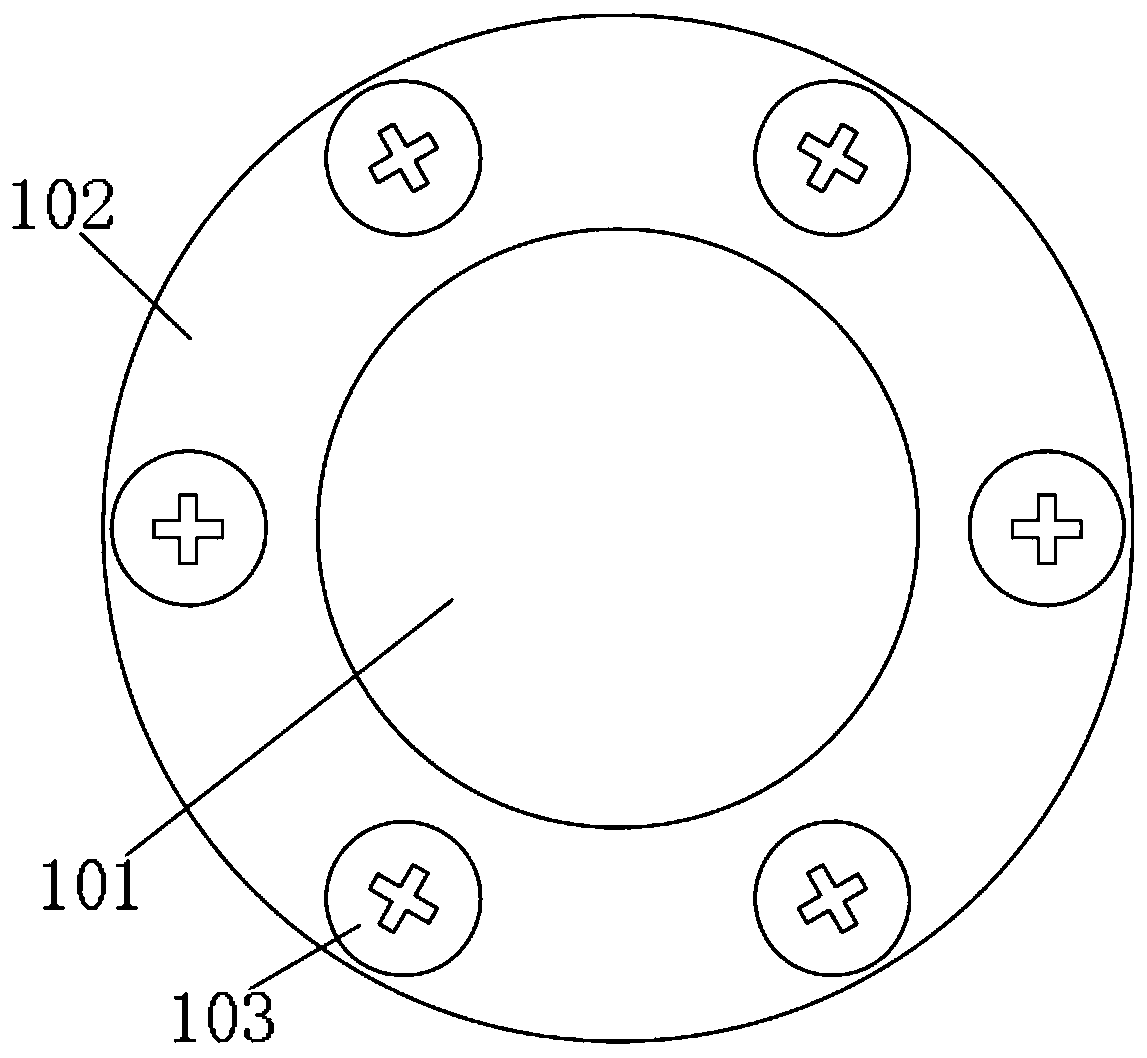

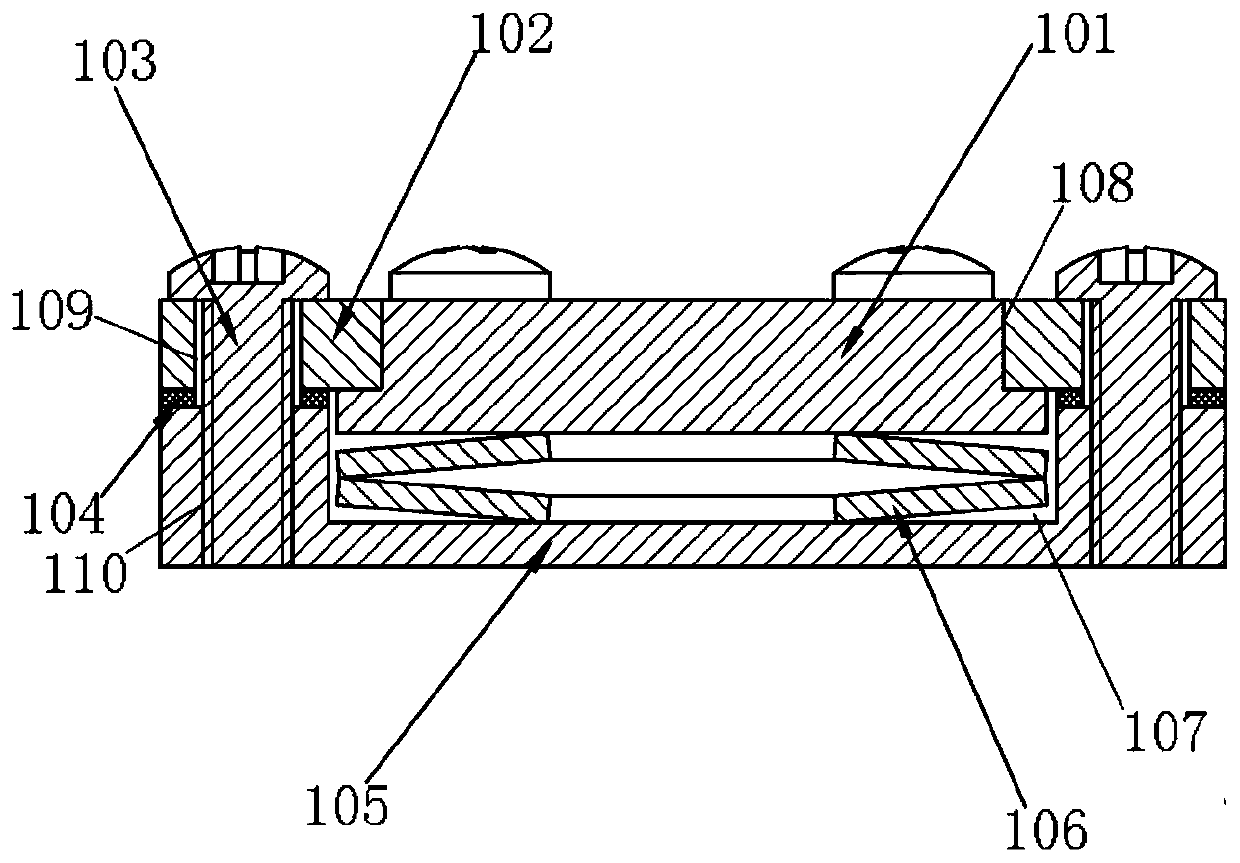

[0039] Such as figure 1 and 2 As shown, the mechanical molecular spring unit body device includes a piston 101, a cover plate 102, a base 105, and a disc spring 106; the cover plate 102 is fixed on the base 105, and a through hole 108 is provided in the middle part of the cover plate 102; There is a blind hole 107; the disc spring 106 is located in the blind hole 107 of the base 105; the piston 101 is in sealing and sliding fit with the through hole 108 of the cover plate 102, the piston 101 is a stepped shaft, and its stepped surface fits with the lower end surface of the cover plate 102, and the piston 101 The lower end surface of 101 is in contact with disc spring 106 .

[0040] Wherein, the connection between the cover plate 102 and the base 105 is provided with 6 connection holes 109, and the base 105 is provided with 6 threaded holes 110 corresponding to the connection holes 109 one by one, and each pair of connecti...

Embodiment 2

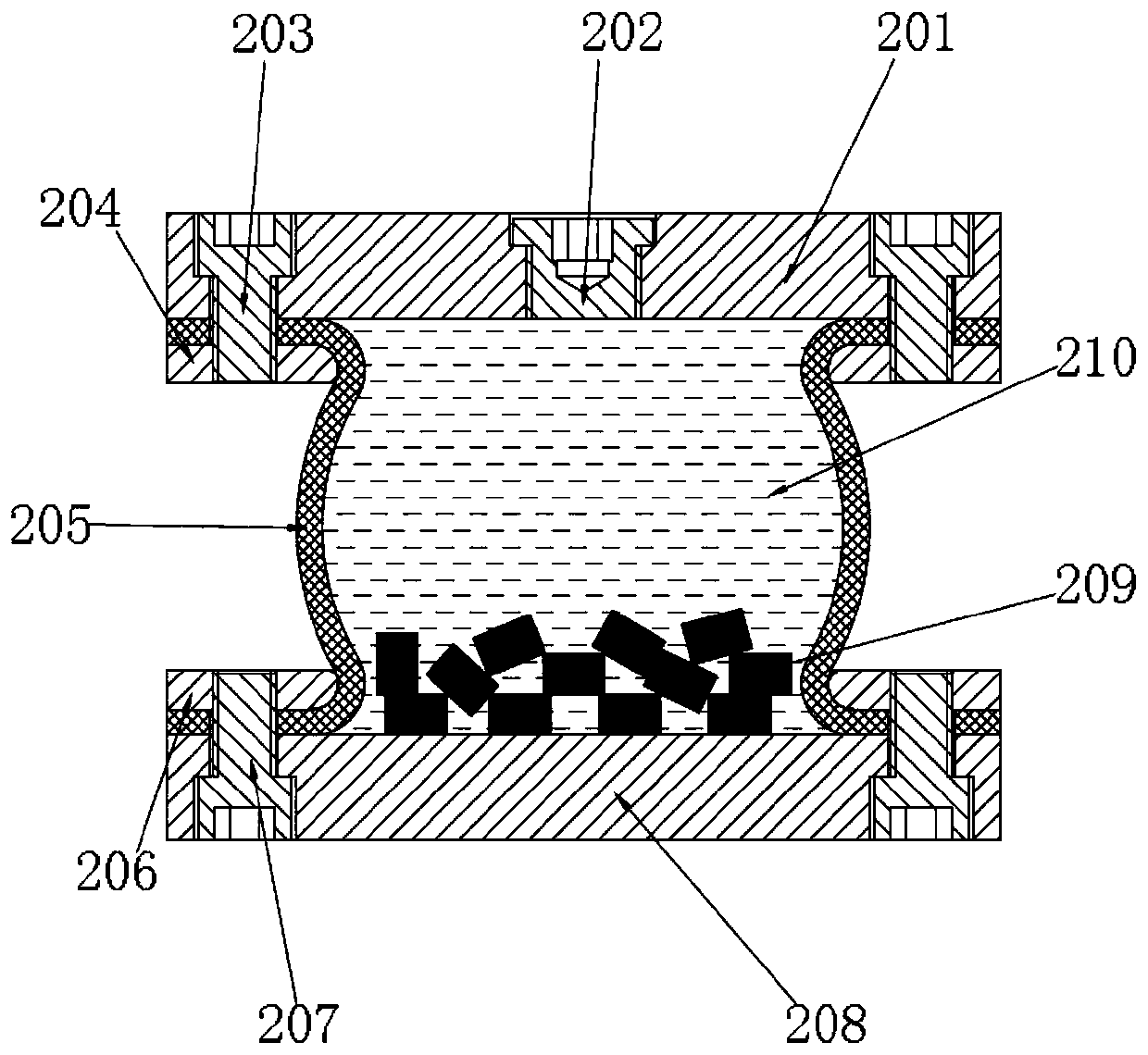

[0045] Capsule Vibration Isolator Based on Mechanical Molecular Spring Unit Device

[0046] Such as image 3 As shown, the capsule vibration isolator based on the mechanical molecular spring unit device includes an upper cover plate 201 , a plug 202 , a rubber bladder 205 , a lower bottom plate 208 , several mechanical molecular spring unit devices 209 , and a liquid 210 . The middle part of the upper cover plate 1 is provided with a countersunk threaded through hole, and is sealed with the plug 202 through thread cooperation; the upper cover plate 201 is provided with 6 countersunk holes, and the upper flange 204 is provided with 6 threaded through holes, through the upper Screws 203 fasten the upper cover plate 201 and the upper flange 204; a rubber bag is provided between the upper cover plate 201 and the upper flange 204 for sealing; the lower base plate 208 is provided with 6 countersunk holes, and the lower flange 206 There are 6 threaded through holes, and the lower bo...

Embodiment 3

[0050] Bellows Vibration Isolator Based on Mechanical Molecular Spring Unit Device

[0051] Such as Figure 4 As shown, the bellows type vibration isolator based on the mechanical molecular spring unit device includes an upper cover plate 301, a plug 302, a bellows 303, a lower bottom plate 304, a mechanical molecular spring unit device 305, a liquid 306, and an upper cover plate 301 There is a countersunk threaded through hole in the middle, and it is sealed with the plug 302 by threading; the upper cover plate 301 is connected and sealed with the bellows 303 by welding; the lower bottom plate 304 is connected and sealed with the bellows 303 by welding; the upper cover plate 301 , the lower bottom plate 304 , and the bellows 303 form a closed cavity, and several mechanomolecular spring unit devices 305 are placed in the cavity, and the cavity is filled with liquid 306 at the same time, and the liquid 306 can be water or hydraulic oil.

[0052] The mechanomolecular spring uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com