Direct current furnace condensate recovery system and method based on high and low pressure condensate flash tanks

A technology of drain expansion and drain recovery, which is applied in the field of drain recovery system of non-starting circulating pump DC furnace, can solve the problem of complex start-up system of recirculation pump, high investment of start-up system of start-up drain heat exchanger, relatively high loss of working medium and heat Large and other problems, to achieve the effect of increasing initial investment and operation and maintenance costs, reducing the amount of water replenishment and fuel consumption, and reducing the loss of working fluid and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

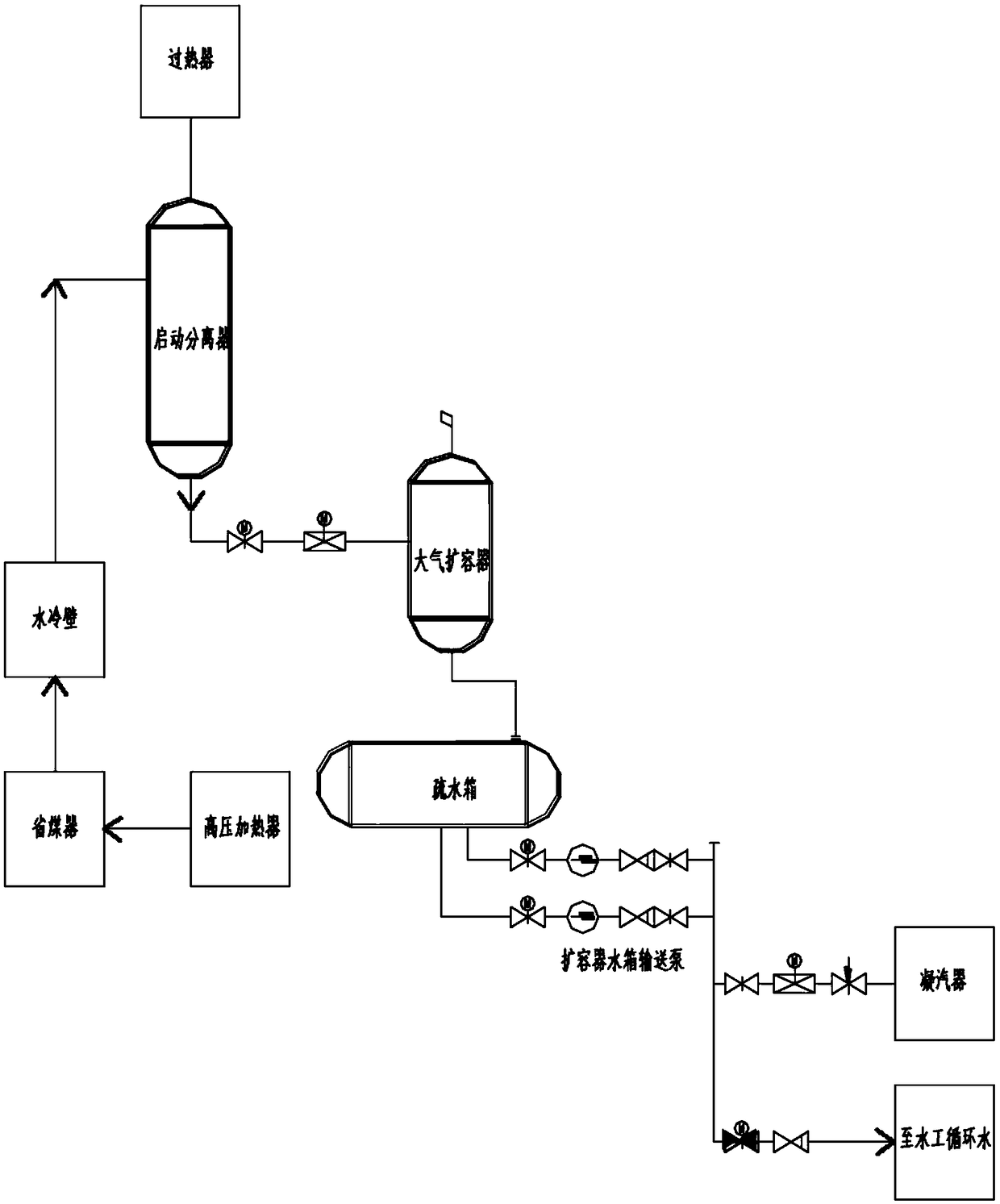

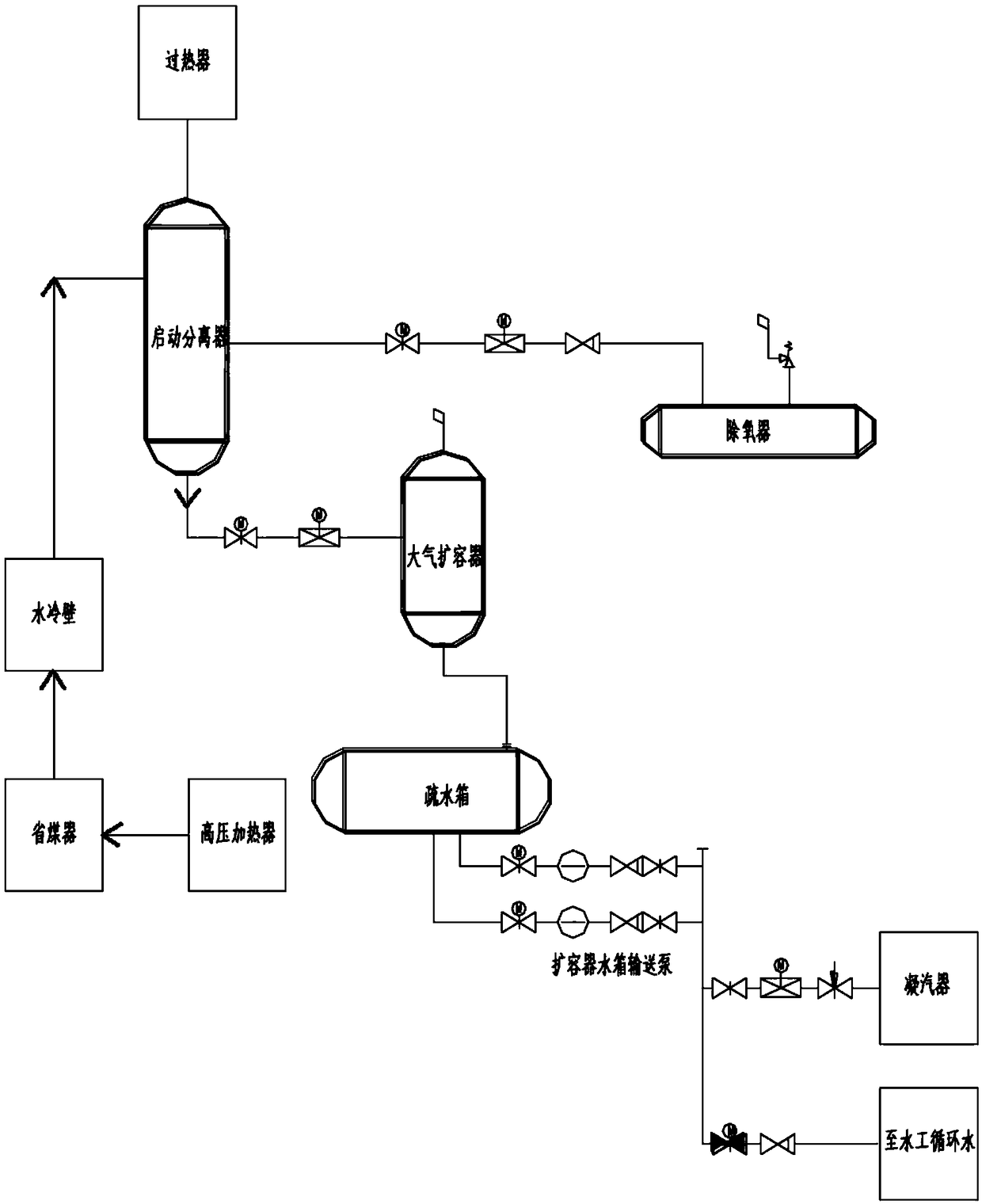

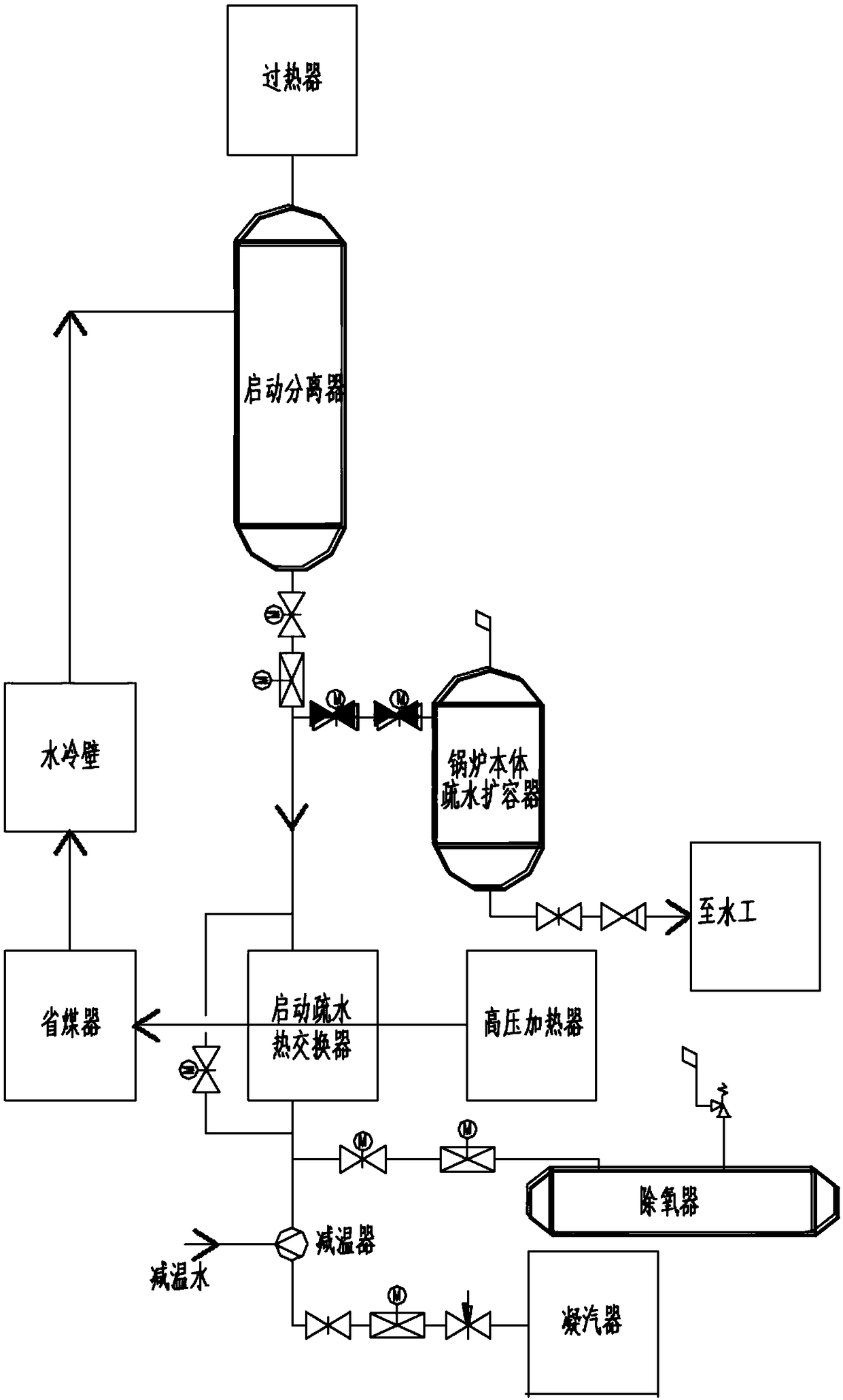

[0058] In a typical implementation of the present application, such as figure 1 As shown, a non-starting circulation pump direct current furnace drainage recovery system based on high and low pressure drainage expansion vessel is provided, the system includes separator 1, separator water storage tank 2, high pressure drainage expansion vessel 3, low pressure drainage expansion vessel 4, Oxygenator 5, condenser 6, unit drainage tank 7 and other steam users 8; the high-pressure hydrophobic expansion vessel 3 and the low-pressure hydrophobic expansion vessel 4 are the integral structure of the hydrophobic expansion vessel and the water tank.

[0059] The separator 1 is connected to the separator water storage tank 2, and the separator water storage tank 2 is connected to the high-pressure hydrophobic expansion vessel 3, and the pressure of the high-pressure hydrophobic expansion vessel 3 is between the pressure of the separator 1 and the pressure of the deaerator 5 , slightly hig...

Embodiment 2

[0069] Taking the cold start of the unit as an example, the operation mode of the non-starting circulating pump DC boiler drainage recovery system based on the high-pressure drainage expansion vessel and the low-pressure drainage expansion vessel proposed in Example 1 is described in detail as follows:

[0070] In the initial stage of unit start-up, before ignition, cold cleaning is required. After the water supply is completed, the boiler is cold cleaned. The feed water passes through the economizer, furnace water wall, water wall outlet mixing header, separator 1 and separator water storage tank. 2. Then drain to the high-pressure drain expander 3 through the drain water level regulating valve 11. If the iron content in the outlet water of the separator storage tank is greater than 1000 μg / L, the drain will enter the low-pressure drain expander 4 through the regulator valve 6 21, and start the drain pump 9. The check valve four 22 is discharged to the unit drainage tank 7. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com