Safety protection system with functions of automatic detection of environmental risk and warning

An environmental risk and safety protection technology, applied in the field of safety protection systems, can solve problems such as poor working conditions, fatigue and irritability of production workers, production safety regulations, and poor implementation of safety measures, so as to avoid accidental injuries to personnel and equipment. The effect of security incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

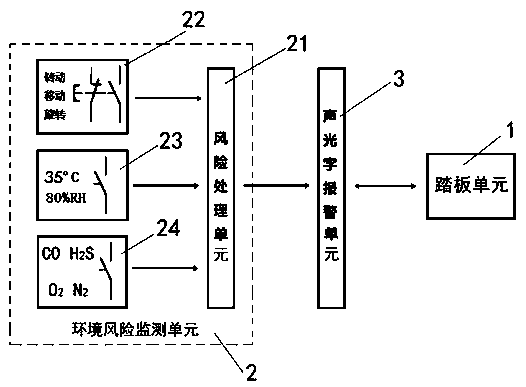

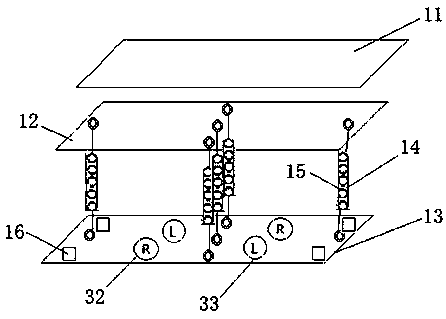

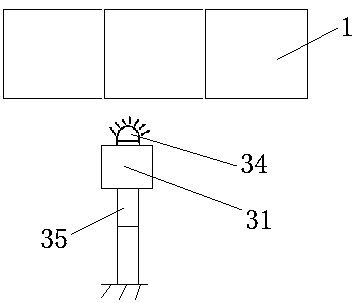

[0018] Example figure 1 , figure 2 and image 3 As shown, the safety protection system with automatic detection of environmental risks and warning functions of the present invention includes a pedal unit 1, an environmental risk monitoring unit 2 and an audible and visual alarm unit 3;

[0019] The pedal unit 1 includes a non-slip stepping surface 11, a support plate and a stepping micro-motion mechanism, the anti-slip stepping surface 11 is a colorless transparent non-slip cushion; the support plate includes an upper plate 12 and a lower plate 13 with a frame, the The upper plate 12 and the lower plate 13 are connected by the internally threaded connecting rod 14 at the midpoint of the four sides of the plate and the intersection of the diagonals. The second plate is perforated and fixed with the internal thread of the connecting rod 14 by bolts. The upper plate 12 is a colorless and transparent plate, and the pedal micro-motion mechanism is four foot switches 16 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com