Method for determining content of metal impurities in thorium dioxide

A metal impurity, thorium dioxide technology, applied in the field of analysis and detection, can solve the problems of thorium matrix concentration detection, such as large influence, poor reproducibility, cumbersome operation, etc., and achieve simple operation, high precision and accuracy, and overcome the matrix effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in detail below in conjunction with specific embodiments of the present invention, but the following examples are only used to understand the present invention, and cannot limit the present invention. The embodiments in the present invention and the characteristics in the embodiments Combinable with each other, the invention can be implemented in a multitude of different ways as defined and covered by the claims.

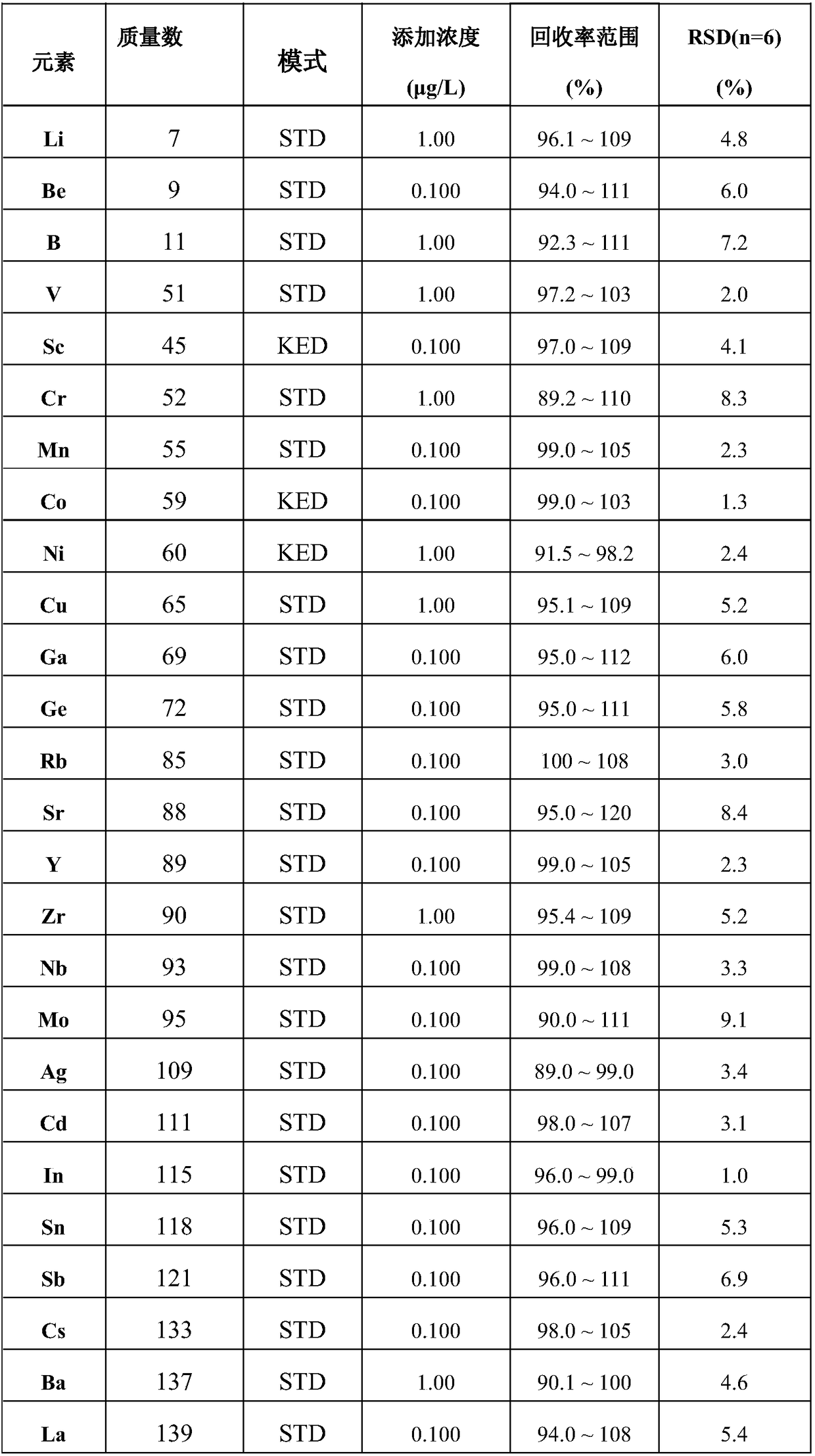

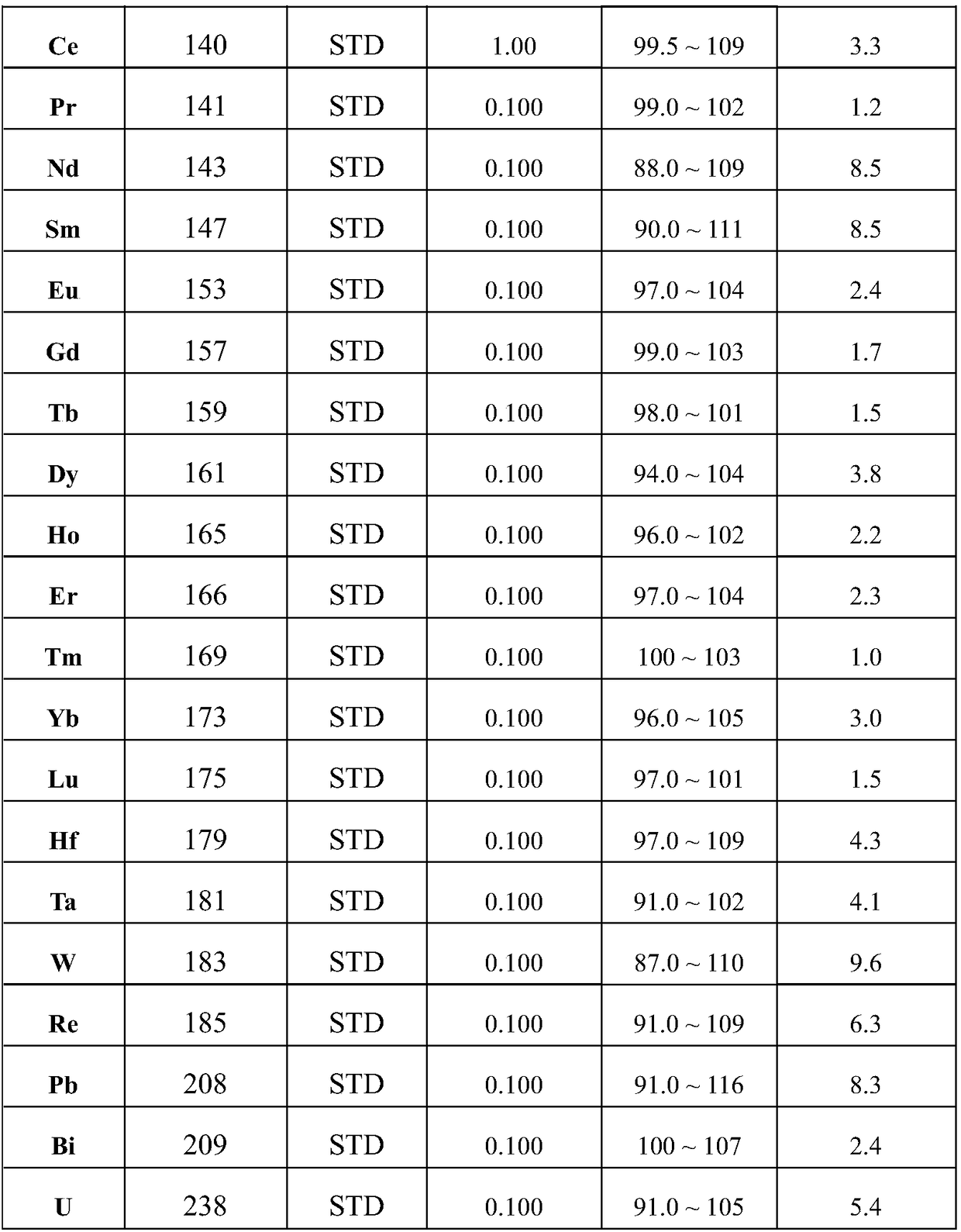

[0027] The invention provides a method for measuring metal impurities in thorium dioxide, comprising the following steps:

[0028] SS1, using microwave digestion to digest thorium dioxide samples to prepare a solution containing thorium dioxide matrix;

[0029] Specifically, 3 samples of high-purity thorium dioxide were weighed, each about 0.1 g, accurate to 0.0001 g, and placed in three microwave digestion inner tanks, respectively, on a 100-grade workbench in a 10,000-grade clean room. Add 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com