Ultrasonic phased array detection imaging system

An ultrasonic phased array and imaging system technology, applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices, which can solve the problems of accuracy, instrumentation, digitization, and portability , Insufficient multi-functionality and other problems, to achieve the effect of enhancing anti-interference ability, reducing error and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

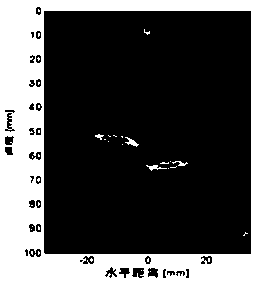

Image

Examples

Embodiment

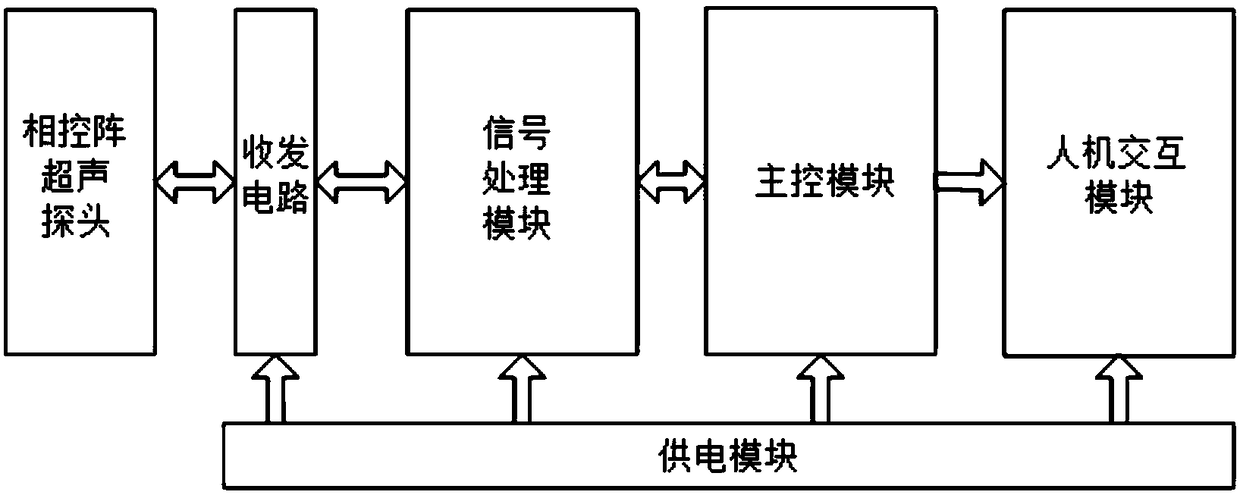

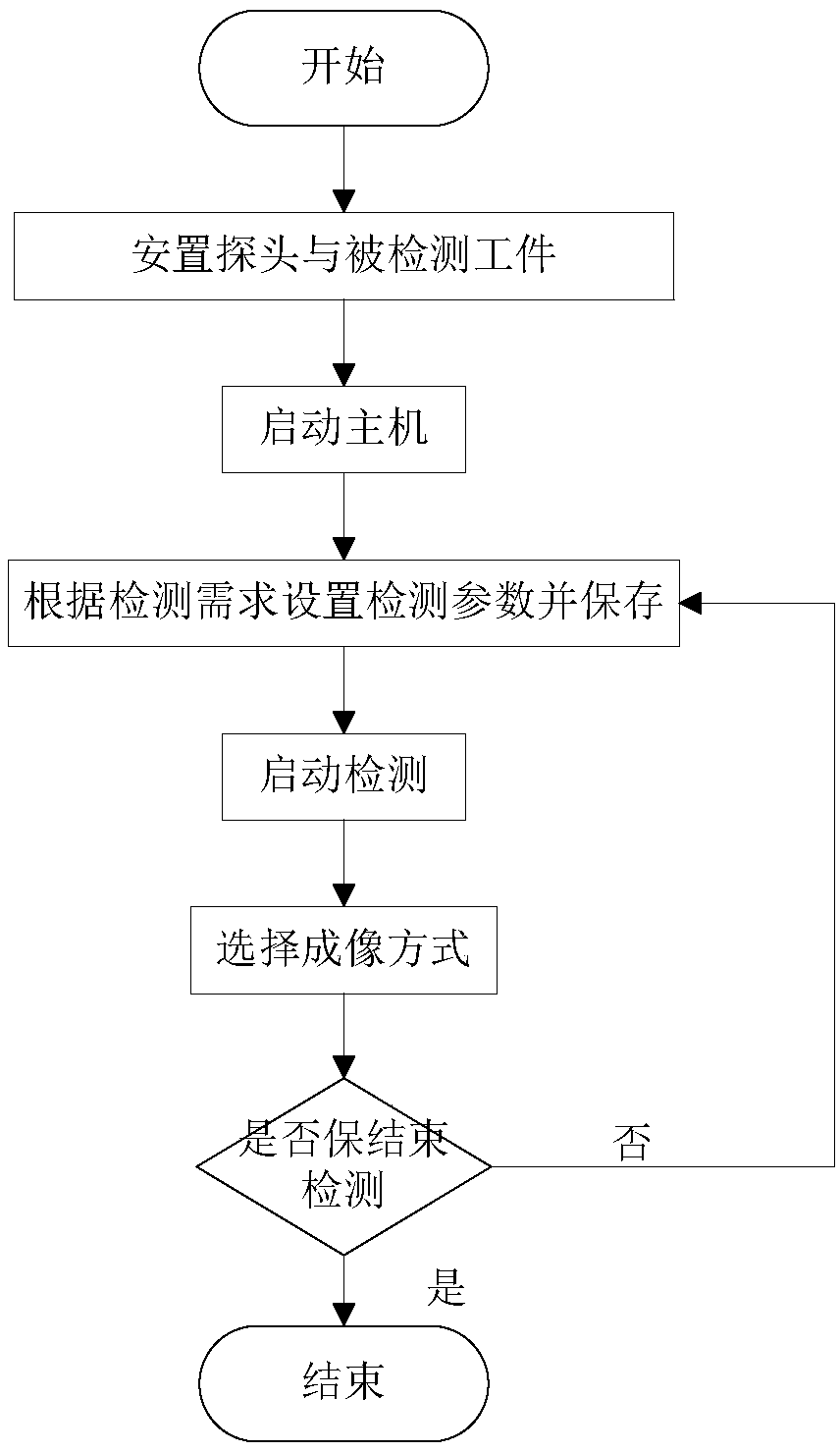

[0055] An ultrasonic phased array detection imaging system, such as figure 1 , including a phased array ultrasonic probe, a transceiver circuit, a signal processing module, a main control module and a human-computer interaction module. machine interaction module,

[0056] Phased array ultrasonic probe: used to place on the surface of the workpiece to be detected, and couple with the workpiece to be detected through the coupling agent, according to the set focusing law, generate an ultrasonic beam corresponding to the angle and focus depth;

[0057] Transmitting and receiving circuit: According to the electric pulse control signal issued by the signal processing module, an electric pulse signal is generated, and the detection echo data collection is realized, including the transmitting circuit and the receiving circuit;

[0058] Signal processing module: Realize the delivery of detection configuration parameters of the main control module, responsible for controlling the exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com