A method for simulating and testing radial local moisture damage of cables

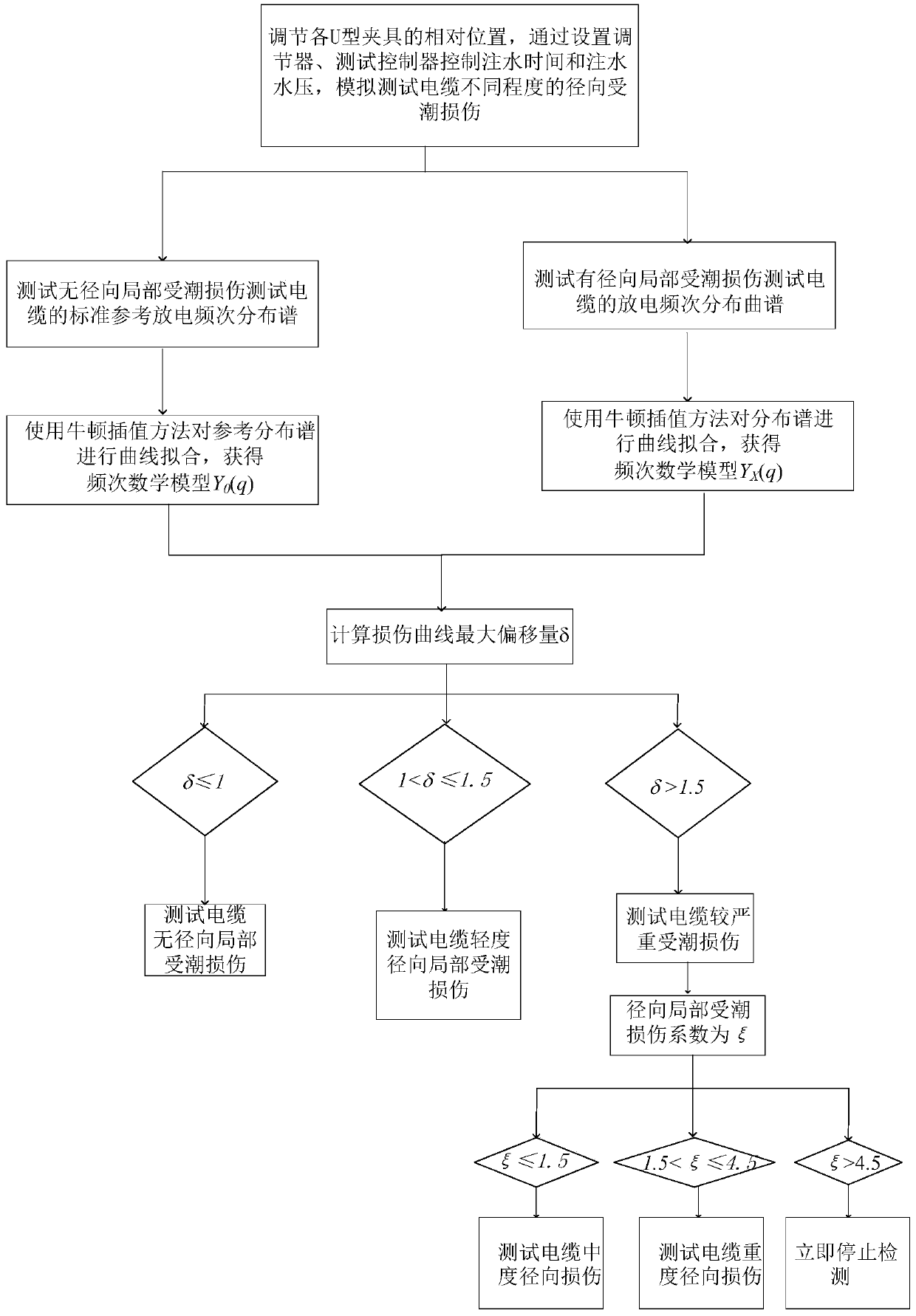

A technology of damage simulation and testing method, applied in the fault location and other directions, which can solve the problems such as the lack of a clear method to detect the radial local moisture of the motor car cable, and it is difficult to obtain the cable damaged by the radial local moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with embodiment.

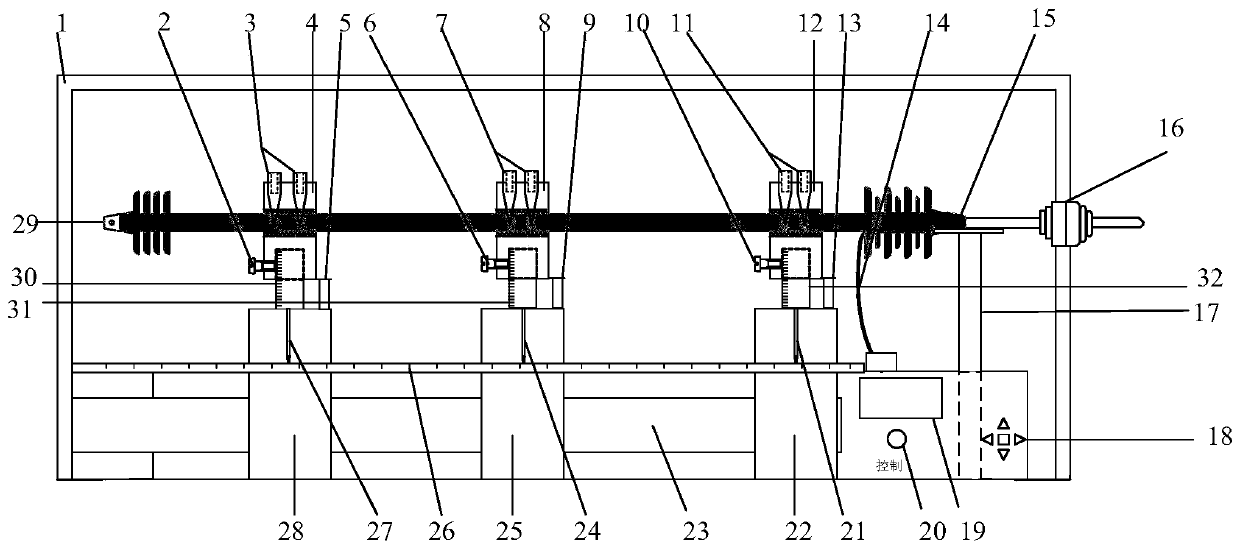

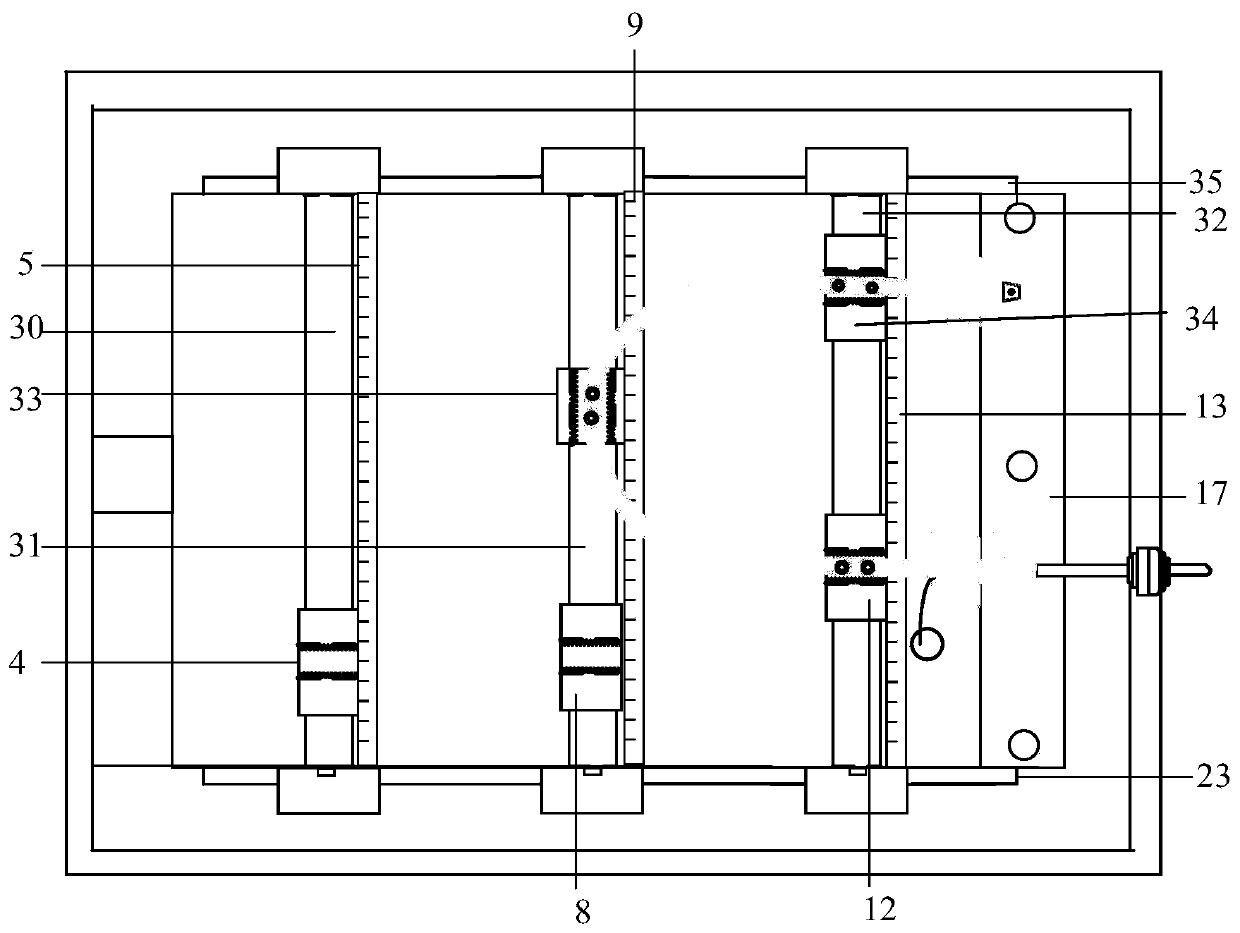

[0063] figure 1 , figure 2 Shown is a structural schematic diagram of the fault simulation device of the present invention, including an isolation box (1), a height adjustment knob 1 (2), a wedge-shaped hollow acupuncture assembly 1 (3), a U-shaped clamp 1 (4), a longitudinal scale 1 (5 ), height adjustment knob 2 (6), wedge-shaped hollow acupuncture assembly 2 (7), U-shaped clamp 2 (8), longitudinal scale 2 (9), height adjustment knob 3 (10), wedge-shaped hollow acupuncture assembly 3 (11), U-shaped fixture 3 (12), longitudinal scale 3 (13), U-shaped fixture 4 (33), U-shaped fixture 5 (34), signal transmission test line (14), cable terminal input port (15) ), high voltage bushing (16), connection test bench (17), setting regulator (18), data display (19), test controller (20), slide test pointer 1 (21), support assembly 3 (22) , Horizontal sliding rod 1 (23), horizontal sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com