Special temperature data acquisition and analysis system for flue gas waste heat system

A temperature data collection and analysis technology, applied in thermometers, temperature control, thermometers using directly heat-sensitive electric/magnetic components, etc., can solve problems such as polluting the environment, wasting energy, and underutilizing waste heat, etc., and achieve system structure Simple, easy operation and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

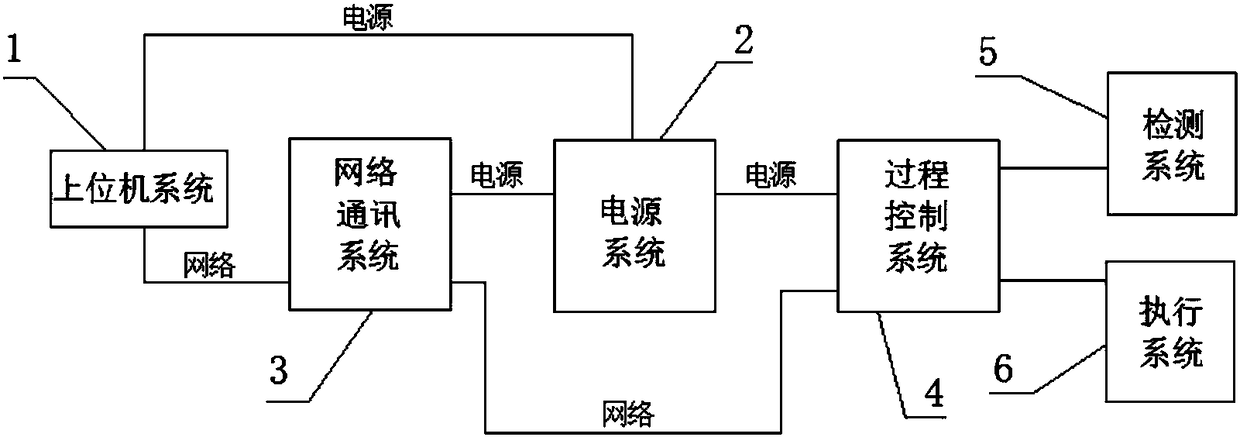

[0040] Such as figure 1 As shown, a temperature data acquisition and analysis system dedicated to the flue gas waste heat system of the present invention includes a host computer system 1, a power supply system 2, a network communication system 3, a process control system 4, a detection system 5 and an execution system 6, and the host computer system 1 Connect the power supply system 2 and the network communication system 3 , the network communication system 3 connects the power supply system 2 and the process control system 4 , and the process control system 4 connects the power supply system 2 , the detection system 5 and the execution system 6 .

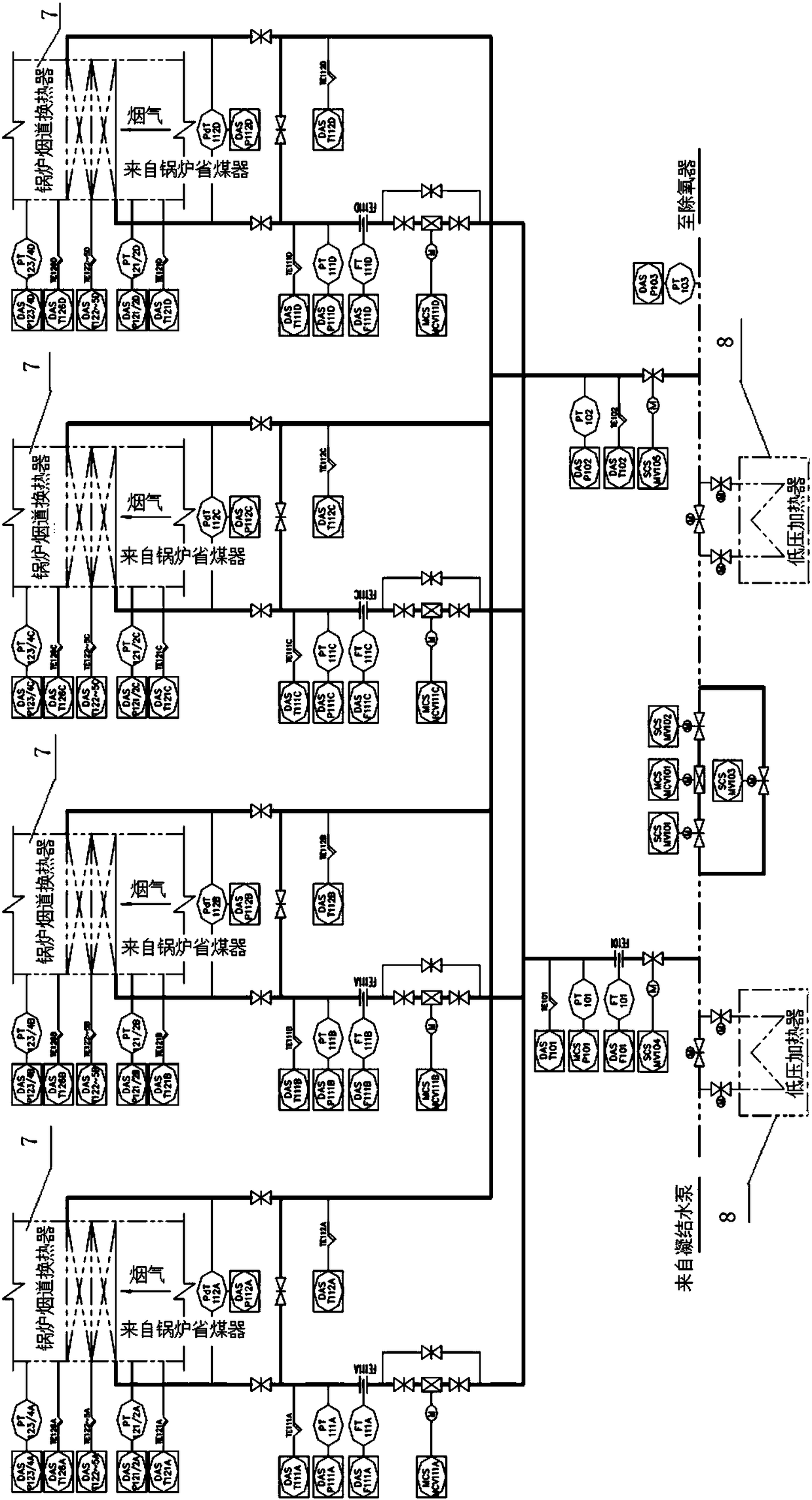

[0041] Such as figure 2 As shown, the flue gas waste heat system using the temperature data acquisition and analysis system also includes four boiler flue heat exchangers 7 and two low-pressure heaters 8 .

[0042] Such as Figure 1-2 As shown, the process automation control and thermal parameter monitoring system of the flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com