Neutron shielding protection material

A shielding protection, neutron technology, applied in shielding, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of reducing the sub-shielding effect, etc., to extend service life, improve thermal conductivity, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

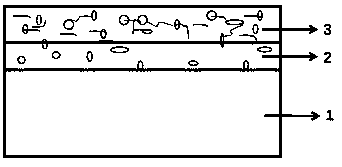

[0034] A neutron shielding protection material, including a base layer obtained from pure boron carbide material, the special feature is that the surface of the base layer is also combined to form a surface layer with a higher thermal conductivity than the base layer.

[0035] In this way, the base layer of this material is obtained from pure boron carbide material, which can ensure a good neutron shielding effect. At the same time, the surface of the base layer forms a surface layer with high thermal conductivity due to the combination, so it can rely on the surface layer with high thermal conductivity. The heat of the base layer is conducted and dissipated outwards, thereby preventing performance degradation of the base layer due to excessive temperature. Therefore, this material not only has a good neutron shielding effect, but also has a good anti-high temperature effect. The heat dissipation method is adopted to improve the heat dissipation effect of the material itself, t...

experiment example 1

[0058] Experimental Example 1: Under the premise of meeting the requirements of the above examples, 389.9 mg of boron carbide powder, 10.05 mg of graphene powder, 355.1 mg of boron carbide, 10.05 mg of graphene, and 8.5 mg of carbon nanotubes were added to the alcohol solution and dispersed uniformly by ultrasonic 60 minutes, stirring on an electromagnetic stirrer for 30 minutes, and ball milling for 2 hours at a speed of 150 r / min. Among them, the carbon nanotubes are the second non-hydroxylated multi-walled carbon nanotubes, the tube walls of which are more complete and do not contain a large number of functional groups, especially hydrogen-containing functional groups. Stir and dry the homogeneously mixed solution on a magnetic stirrer. The base layer of the regrinding tool is covered with pure boron carbide powder, the middle layer is covered with mixed powder of boron carbide and graphene, and the surface layer is covered with mixed powder of boron carbide, graphene and c...

experiment example 2

[0060]Experimental Example 2: Under the premise of meeting the requirements of the above examples, 365.4 mg of boron carbide powder, 15.22 mg of graphene powder, 365.4 mg of boron carbide, 10.45 mg of graphene, and 15.5 mg of carbon nanotubes were added to the alcohol solution and dispersed uniformly by ultrasonic 90 minutes, stirred on an electromagnetic stirrer for 30 minutes, and ball milled for 3 hours at a speed of 200 r / min. Among them, the carbon nanotubes are selected from the first hydroxylated multi-wall carbon nanotubes, and a large number of hydroxyl functional groups are attached to the tube walls. Stir and dry the homogeneously mixed solution on a magnetic stirrer. The base layer of the regrinding tool is covered with pure boron carbide powder, the middle layer is covered with mixed powder of boron carbide and graphene, and the surface layer is covered with mixed powder of boron carbide, graphene and carbon nanotubes. It is pre-pressed into a blank and dried, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com