Image sensor and formation method thereof

A technology of image sensors and optoelectronic devices, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of quantum conversion efficiency that needs to be improved, and achieve the effects of improving quantum conversion efficiency, improving light crosstalk, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

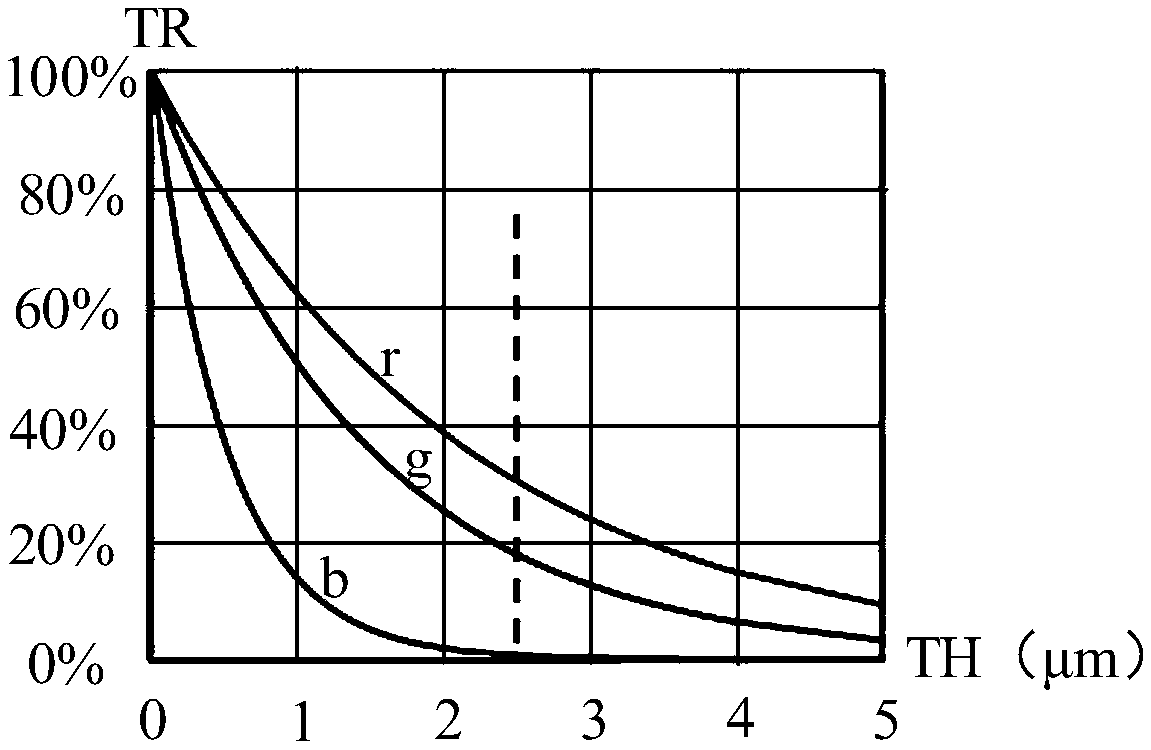

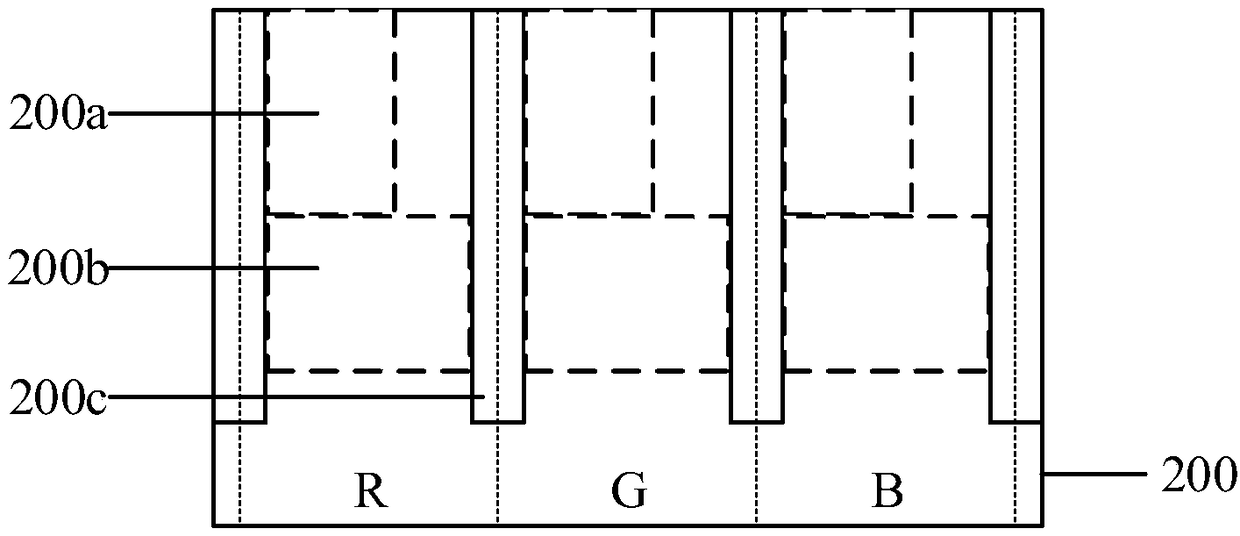

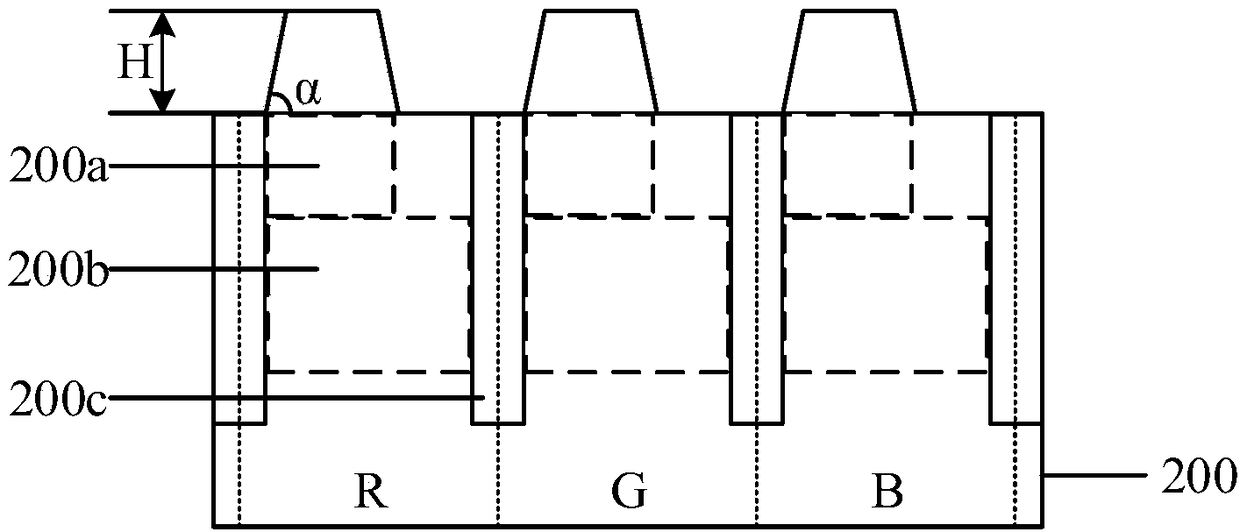

[0026] Such as figure 1 As shown, taking an RGB image sensor as an example, the transmittance (TR, transmittance) of different wavelengths of light on semiconductor substrates with different thicknesses gradually decreases as the thickness (TH, thickness) of the semiconductor substrate increases. In comparison, the light transmittance of red light r is higher than that of green light g, and the light transmittance of green light g is higher than that of blue light b. At present, the R / G / B pixels of the back-illuminated image sensor are produced in the silicon substrate with the same thickness (such as 2.5 μm ~ 3.0 μm), and the blue light b (light transmittance is about 0%) is almost completely absorbed, while some Red light r (light transmittance is about 20% to 30%) and green light g (light transmittance is about 10% to 20%) penetrate the silicon substrate, which reduces the quantum conversion efficiency of light and also produces Light crosstalk and other issues.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com