Direct current motor for electric capstan

A technology of DC motors and electric winches, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of shortening the service life of DC motors, no anti-condensation measures, poor heat dissipation performance of the whole machine, etc., and achieve high protection level , the overall compactness, and the effect of safe motor operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

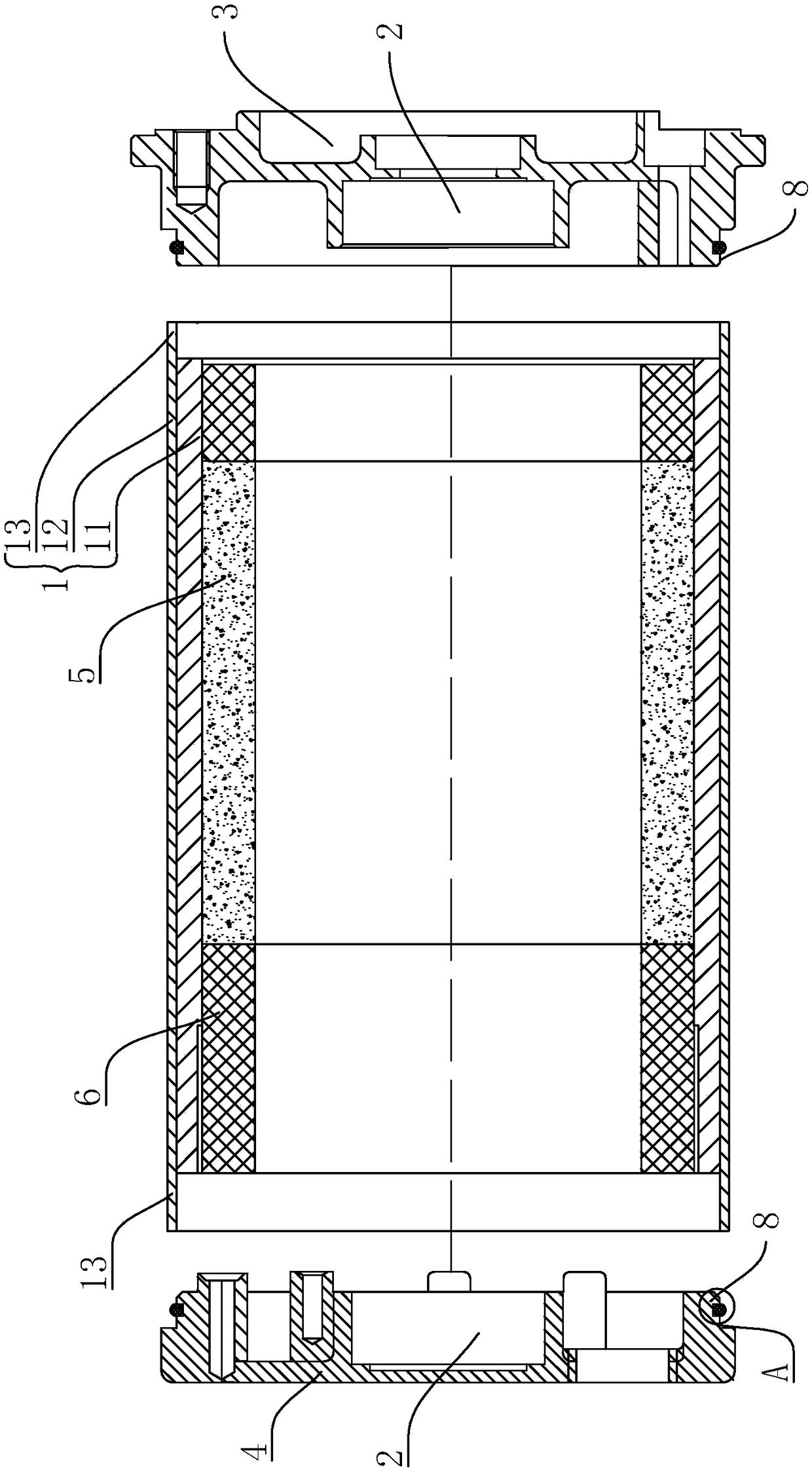

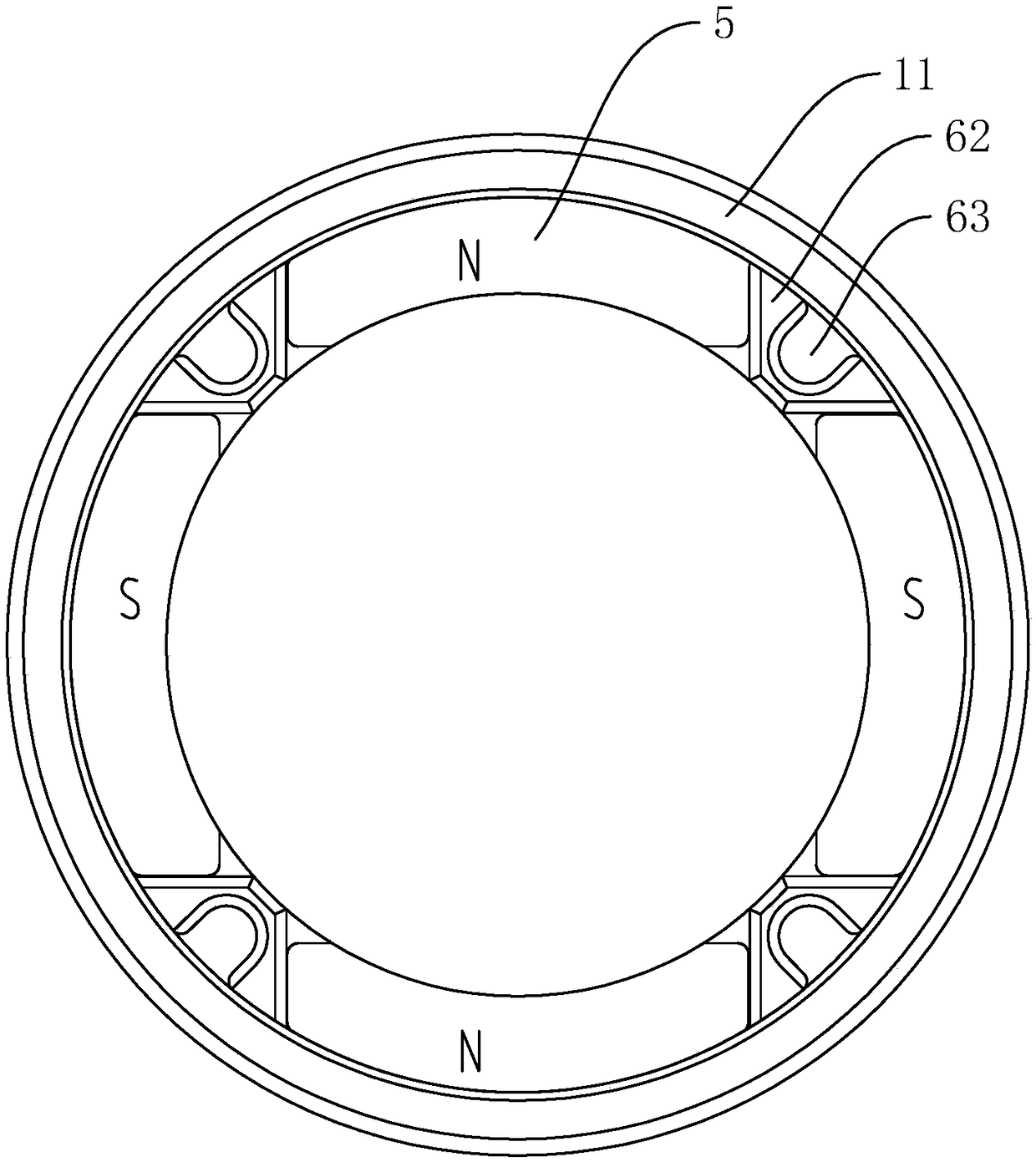

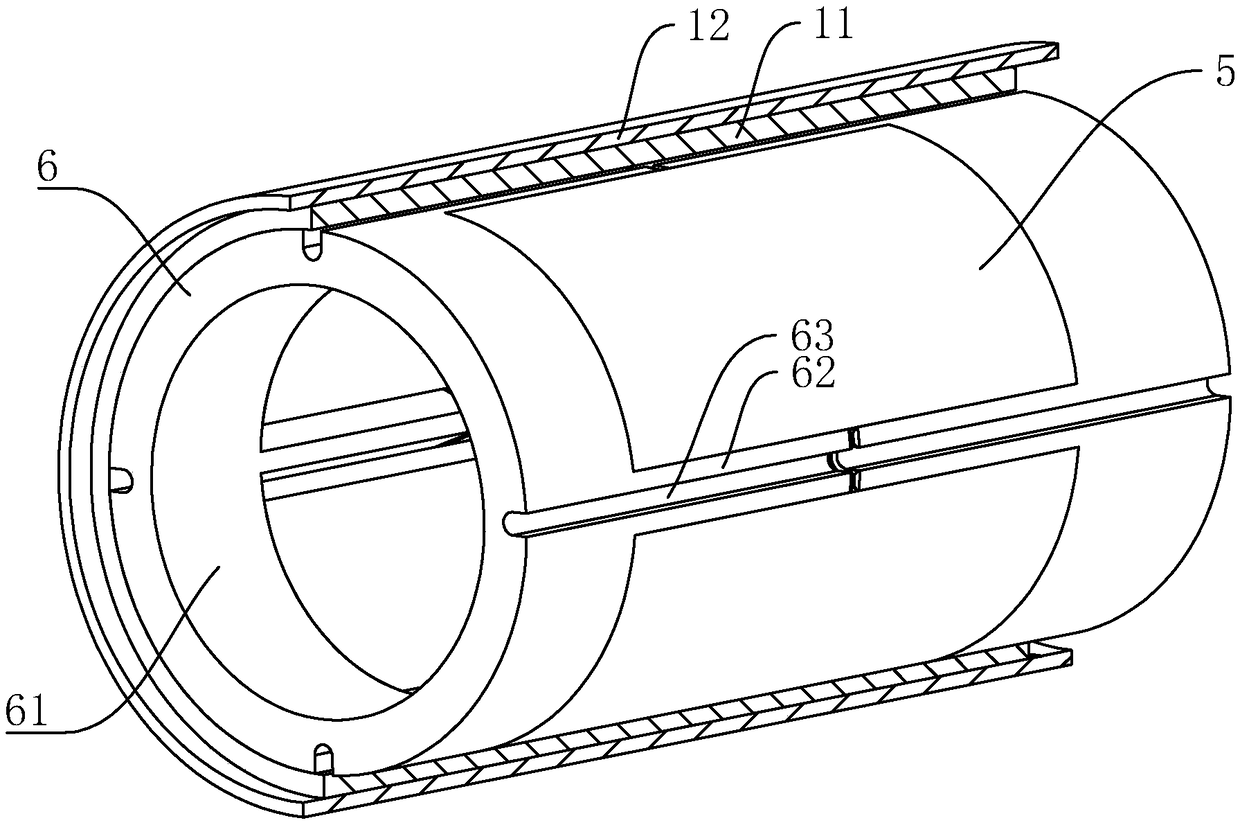

[0036] A kind of DC motor for electric winch, refer to figure 1 , including a composite casing 1, the composite casing 1 is provided with a rotor, the composite casing 1 includes a magnetically conductive casing 11 and a stainless steel casing 12 sleeved outside the magnetically conductive casing 11, and the front end of the composite casing 1 is provided with a front end As for the cover 3, the rear end of the compound casing 1 is provided with a rear end cover 4.

[0037] The stainless steel shell 12 is interference fit with the magnetically conductive casing 11, and the interference between the two is 0.1-0.2 mm, preferably 0.04-0.06 mm. Such arrangement eliminates the gap between the magnetically permeable casing 11 and the stainless steel casing 12, not only reduces the volume of the DC motor, but also facilitates the heat dissipation of the DC motor.

[0038] refer to figure 1 with 2 , There are four uniformly arranged magnetic tiles 5 inside the magnetically conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com