Crispy ball containing haws and chestnut kernels and preparation method thereof

A technique for chestnut and hawthorn, applied in the field of hawthorn chestnut crispy balls and preparation thereof, can solve the problems of poor color, too many additives, single taste, etc., and achieve the effects of simple operation, delicate and moist taste, and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

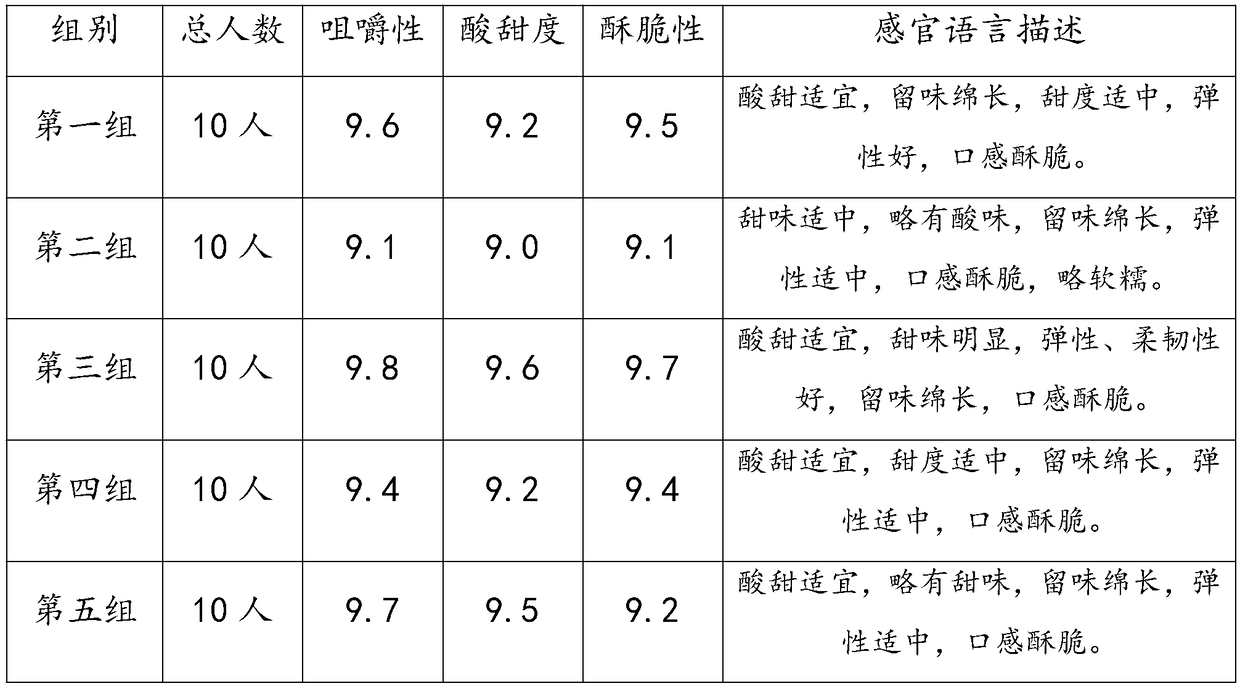

Examples

Embodiment 1

[0035] A hawthorn and chestnut crispy ball comprises the following components in parts by weight: 2 parts of hawthorn fruit powder, 1 part of chestnut powder, 3.5 parts of yam and 0.4 part of white sugar.

[0036] The hawthorn and chestnut crispy balls, the specific steps of its preparation method are as follows:

[0037] (1) Select high-quality, fresh hawthorn fruits, chestnuts, and yams for later use. Wash the hawthorn fruits, remove the pits, and freeze at -22°C for 10 hours. After pretreatment, they are initially crushed to obtain coarse powder. The particle size of the coarse powder is 80 mesh. , the hawthorn superfine powder is obtained by pulverizing again through a jet mill pulverizer;

[0038] (2) Steam chestnuts, shell them, and crush them, raise the temperature to 60°C, control the temperature, raise the temperature and dry until the water content is below 10%, and initially grind to obtain a coarse powder, the particle size of the coarse powder is 80 mesh, and then...

Embodiment 2

[0043] The hawthorn and chestnut crispy ball comprises the following components in parts by weight: 2 parts of hawthorn fruit powder, 1.5 parts of chestnut powder, 4 parts of yam and 0.5 part of white sugar.

[0044] The hawthorn and chestnut crispy balls, the specific steps of its preparation method are as follows:

[0045] (1) Select high-quality and fresh hawthorn fruits, chestnuts, and yams for later use. Wash the hawthorn fruits, remove the pits, and freeze at -21°C for 11 hours. After pretreatment, they are initially crushed to obtain a coarse powder. The particle size of the coarse powder is 85 mesh. , the hawthorn superfine powder is obtained by pulverizing again through a jet mill pulverizer;

[0046] (2) Steam the chestnuts, remove the shells, crush them, raise the temperature to 62°C, control the temperature, raise the temperature and dry until the water content is below 10%, and initially crush them to obtain a coarse powder, the particle size of the coarse powder ...

Embodiment 3

[0051] A hawthorn and chestnut crispy ball comprises the following ingredients in parts by weight: 2 parts of hawthorn fruit, 1 part of chestnut, 4 parts of yam and 0.4 part of white sugar.

[0052] The hawthorn and chestnut crispy balls, the specific steps of its preparation method are as follows:

[0053] (1) Select high-quality and fresh hawthorn fruits, chestnuts, and yams for later use. Wash the hawthorn fruits, remove the pits, and freeze at -20°C for 12 hours before pretreatment, and then crush them to obtain coarse powder. The particle size of the coarse powder is 90 mesh. , the hawthorn superfine powder is obtained by pulverizing again through a jet mill pulverizer;

[0054] (2) Steam the chestnuts, shell them, and crush them, raise the temperature to 63°C, control the temperature, raise the temperature and dry until the water content is below 10%, and initially crush the chestnuts to obtain a coarse powder, the particle size of which is 90 mesh, and then crush it thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com