Method and device for stabilizing arc length

An arc and arc length technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of poor gas shielding effect, no suitable arc, and dark appearance of weld bead, so as to prevent overheating and reduce heat input The effect of stable volume and arc length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

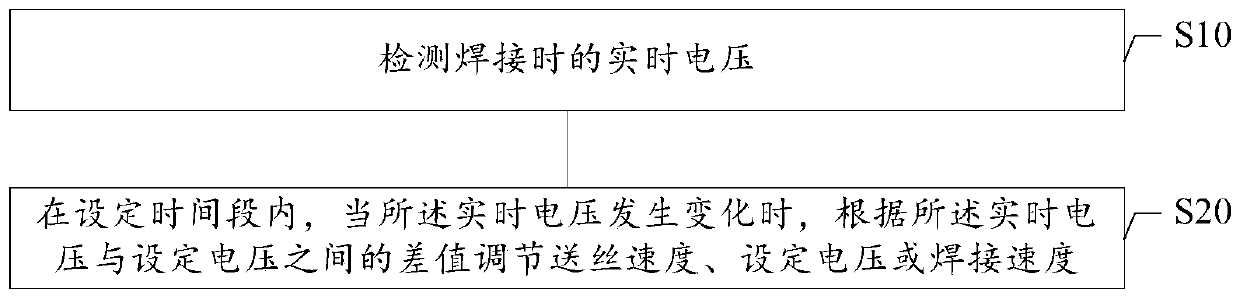

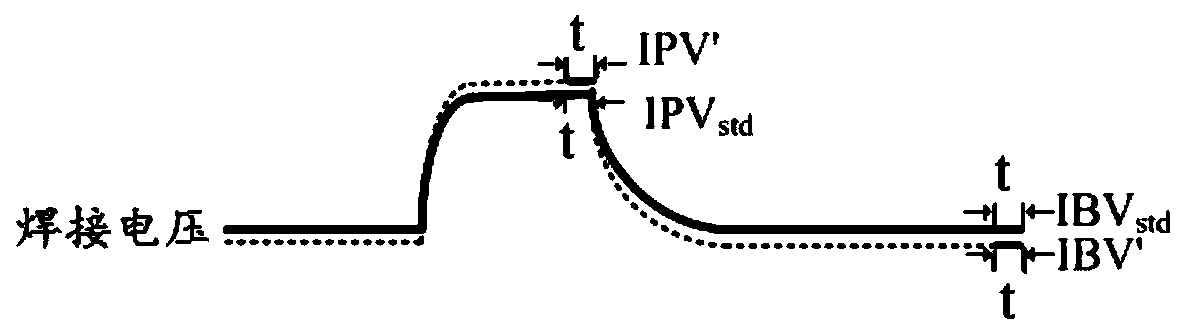

[0053] In this example embodiment, the wire feeding speed or the set voltage is adjusted mainly according to the difference between the peak value of the real-time voltage and the peak value of the set voltage.

[0054] The main process is as follows: firstly, the adjusted wire feeding speed and the adjusted welding speed after adjusting the set voltage are calculated according to the difference between the peak value of the real-time voltage and the peak value of the set voltage.

[0055] The adjusted wire feeding speed calculated according to the difference between the peak value of the real-time voltage and the peak value of the set voltage is:

[0056] MSPD'=MSPD-(IPV'-IPV std )Kp 1 ,

[0057] In the formula, MSPD' is the wire feeding speed after adjustment, MSPD is the wire feeding speed before adjustment, IPV' is the peak value of real-time voltage, IPV std is the peak value of the set voltage, Kp 1 is a coefficient, and its value is a positive number, which can be a...

Embodiment approach 2

[0066] In this example embodiment, the wire feed speed, set voltage or welding speed is adjusted mainly based on the difference between the pulse base value of the real-time voltage and the pulse base value of the set voltage.

[0067] The main process is as follows: firstly, the adjusted wire feeding speed, the adjusted set voltage and the adjusted welding speed are calculated according to the difference between the pulse base value of the real-time voltage and the pulse base value of the set voltage. speed.

[0068] The adjusted wire feeding speed calculated according to the difference between the pulse base value of the real-time voltage and the pulse base value of the set voltage is:

[0069] MSPD'=MSPD+(IBV'-IBV std )Kp 3 ,

[0070] In the formula, MSPD' is the wire feeding speed after adjustment, MSPD is the wire feeding speed before adjustment, IBV' is the pulse base value of real-time voltage, IBV std is the pulse base value of the set voltage, Kp 3 is a coefficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com