Pollution-free transport synchronous release system for giant airships

A pollution-free, airship-free technology, applied in the field of giant airship pollution-free transfer and synchronous release system, can solve the problems of tearing airships, high risks, and many interference factors, and achieve orderly and intensive management, simple and convenient operation, and systematic strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

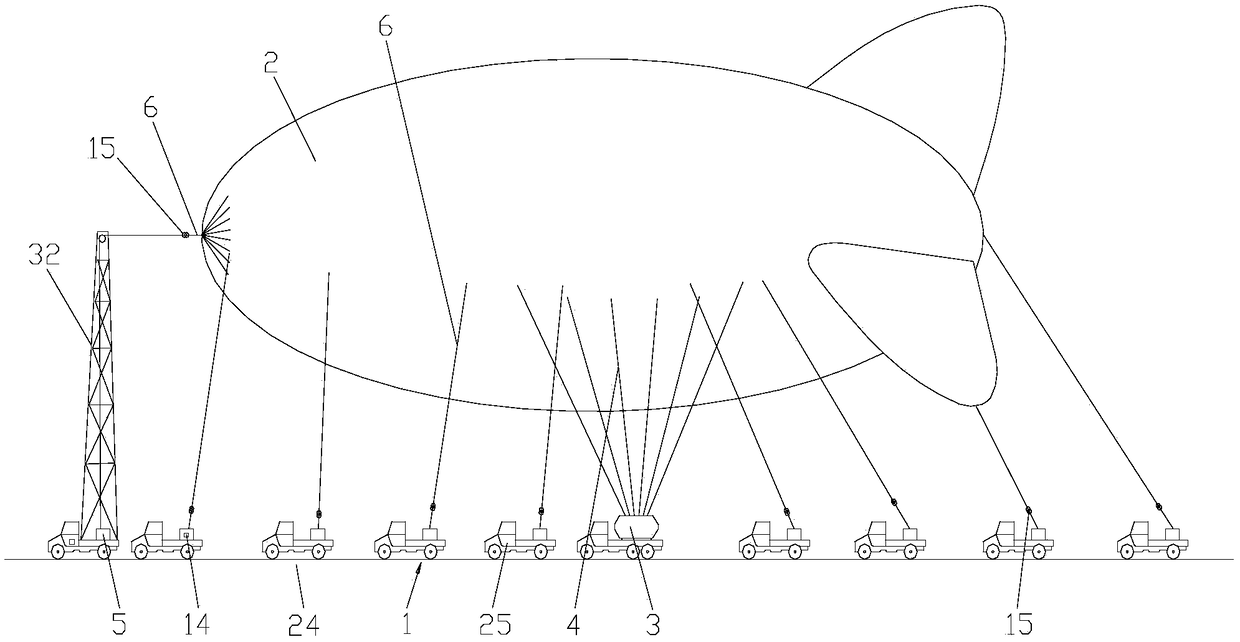

[0038] Embodiment 1: Giant airship pollution-free transfer synchronous release system, such as figure 1 and 2 As shown, it includes a communication system 12 , a central control computer 13 and execution units including a pollution-free flying vehicle device 1 , a mooring module 5 , and a synchronous cutting system 14 .

[0039] The central control computer 13 is located in a fixed control room, and the pollution-free flying vehicle device 1 is provided with a communication system 12 connected to the central control computer 13, and the pollution-free flying vehicle device 1 control system passes through the communication system. 12 is connected with the central control computer 13, and said pollution-free flying vehicle device 1 is provided with a plurality of mooring modules 5, and each mooring module 5 pulls the airship 2 by mooring rope 6, and said mooring The module 5 realizes signal transmission through the communication system 12 and the central control computer 13, an...

Embodiment 2

[0044] Embodiment 2: This embodiment is a further improvement on Embodiment 1. It adopts a distributed vehicle structure. Specifically, as figure 1 As shown, the pollution-free flying vehicle device 1 is a distributed electric fleet flying system 24 composed of a plurality of electric vehicles 25 .

[0045] Such as figure 1As shown, the instrument cabin 3 of the airship 2 is carried on the electric vehicle 25 in the middle, and the instrument cabin 3 is connected to the airship 2 through a plurality of ropes 4, and the mooring tower 32 and the mooring module 5 are carried on the front electric vehicle 25 , responsible for providing horizontal traction for the airship during transportation, and the other said electric vehicles 25 all carry a mooring module 5, and each said mooring module 5 pulls the airship 2 through a mooring rope 6 . Each mooring module 5 includes an electric winch 7 with a length measuring instrument 8 and a tensiometer 9, the electric winch 7 is provided w...

Embodiment 3

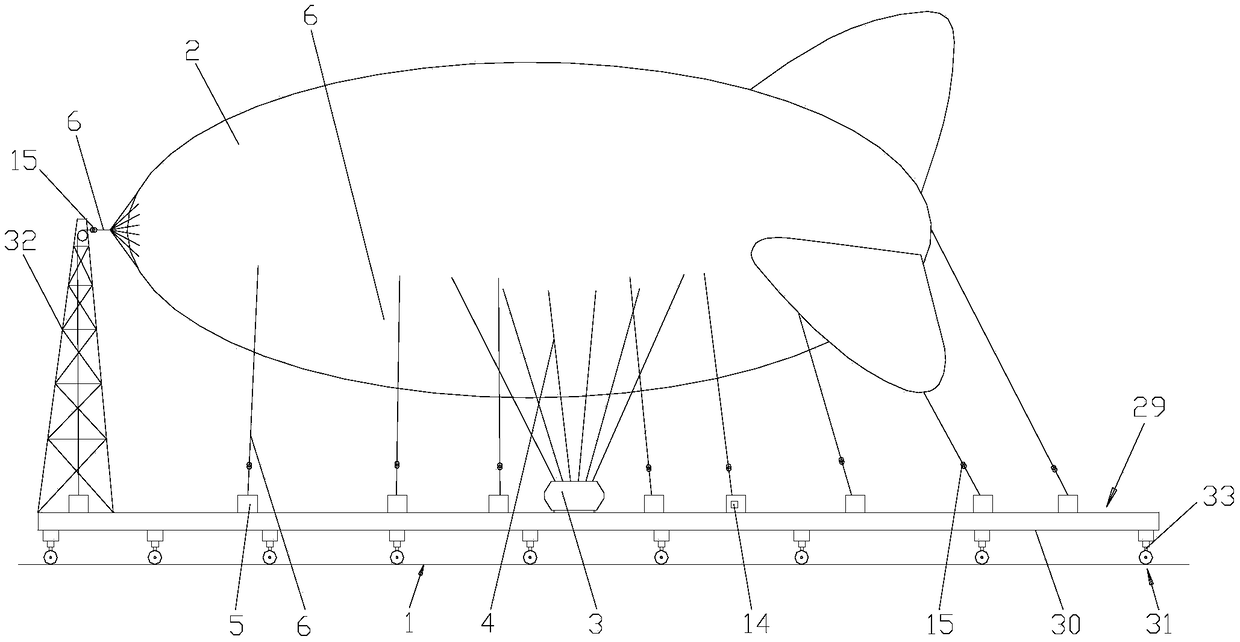

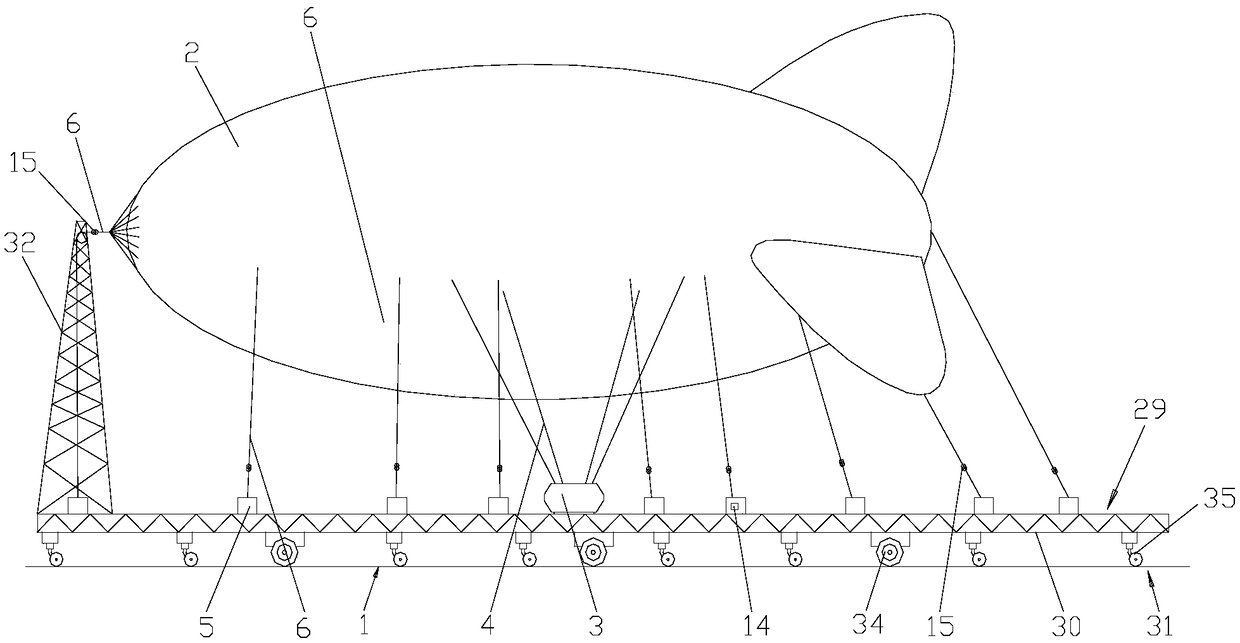

[0051] Embodiment 3: This embodiment is another improvement to Embodiment 1, specifically, as figure 2 As shown, the pollution-free flying vehicle device 1 is made into a pure electric integrated flying vehicle 29, and the pure electric integrated flying vehicle 29 includes a communication system 12, a central control computer 13 and a mooring module 5, a synchronous In addition to the cutting system 14, it also includes an integral vehicle frame 30 and a drive running device 31 located at the bottom of the integral vehicle frame 30.

[0052] Such as Figure 9 As shown, the integral vehicle frame 30 is provided with a vehicle control system 72 and a general electrical switch cabinet 76, and the vehicle control system 72 includes an independent storage battery 71 connected to the central control computer 13, a switch operation panel 86, Optical transceiver 81, remote controller 87. The main electric switch cabinet 76 is used to control the signal lamp 77, the buzzer 78, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com