Polypropylene composite material with high performance and preparation method thereof

A composite material, polypropylene technology, applied in the field of materials, can solve the problems of pressure resistance and durable hydrolysis resistance, and achieve the effects of improved notched impact performance, improved flexural strength and flexural modulus, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

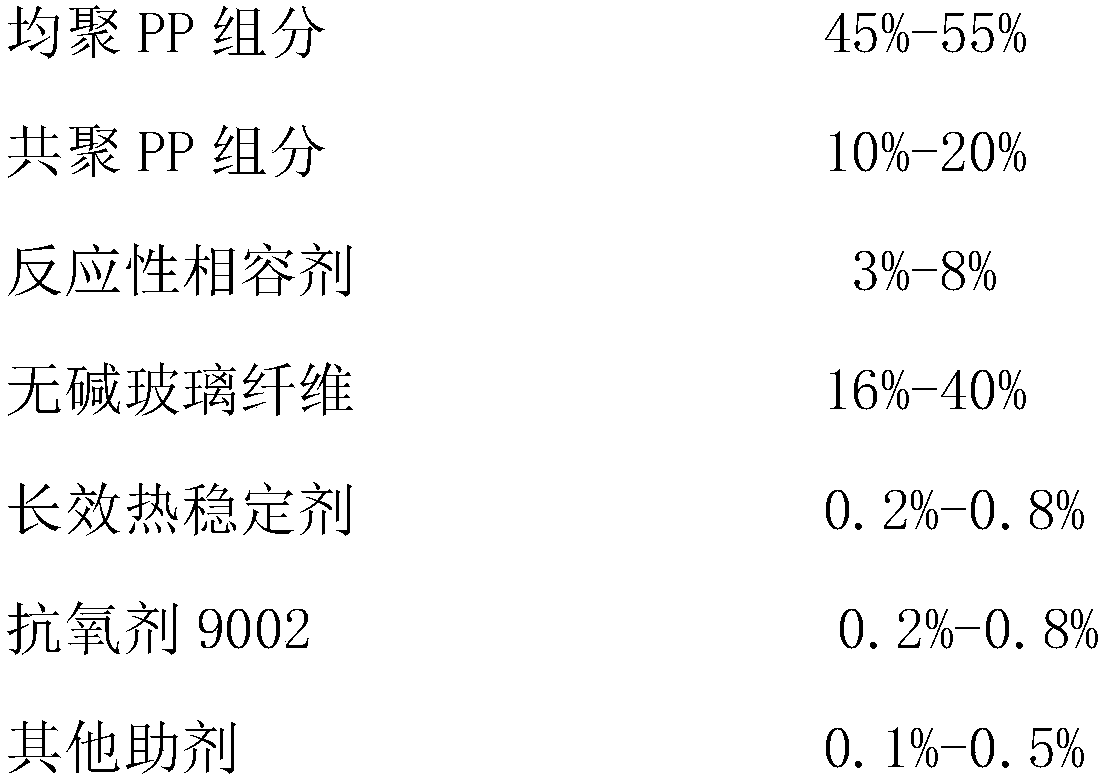

[0020] A high-performance polypropylene composite material consisting of the following raw materials in weight percent:

[0021]

[0022] The above-mentioned homopolymer PP component is homopolypropylene, and its characteristic flexural modulus is 1700MPa;

[0023] The above-mentioned copolymerized PP component is copolymerized polypropylene, and its characteristic notched impact is 45KJ / m 2 ;

[0024] The surface of the above-mentioned alkali-free glass fiber is treated with a silane coupling agent, and the diameter of the single filament is 9 microns;

[0025] The above-mentioned reactive compatibilizer is a polyolefin reactive compatibilizer;

[0026] Other additives are ultraviolet absorber 2 hydroxy-4-n-octyloxybenzophenone;

[0027] Prepared by the following method:

[0028] 1. Ingredients: add homopolymerized PP, copolymerized PP and compatibilizer in the high-speed mixer in sequence according to the weight ratio of the formula, and pre-mix for 5 minutes, add ant...

Embodiment 2

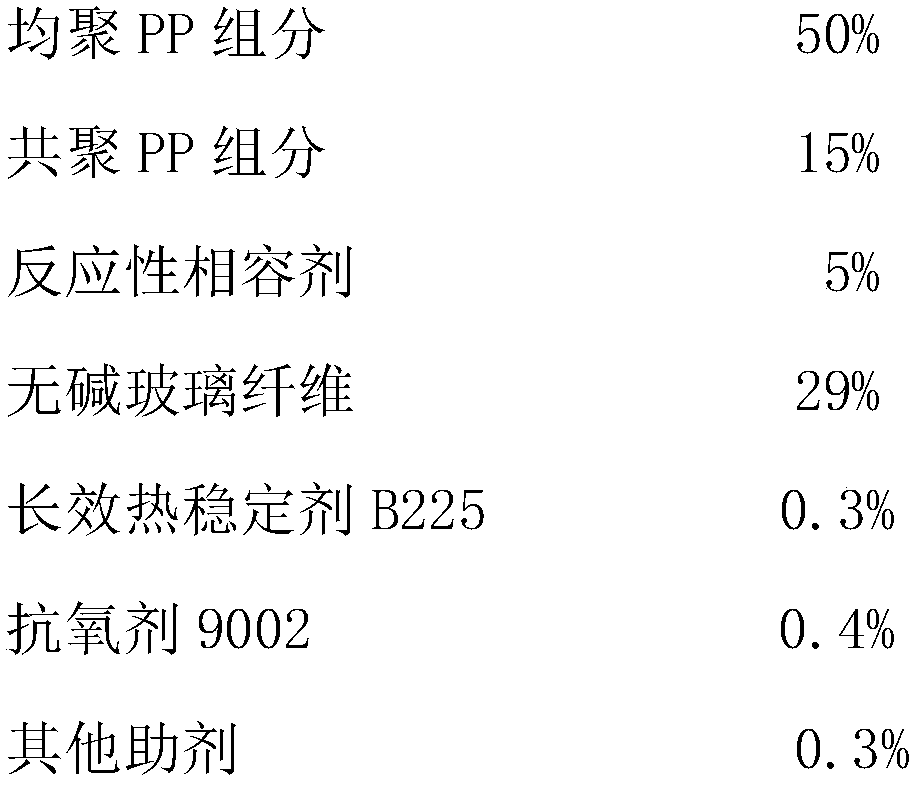

[0032] A high-performance polypropylene composite material consisting of the following raw materials in weight percent:

[0033]

[0034]

[0035] The above-mentioned homopolymer PP component is homopolypropylene, and its characteristic flexural modulus is 1700MPa;

[0036] The above-mentioned copolymerized PP component is copolymerized polypropylene, and its characteristic notched impact is 45KJ / m 2 ;

[0037] The surface of the above-mentioned alkali-free glass fiber is treated with a silane coupling agent, and the diameter of the single filament is 9 microns;

[0038] The above-mentioned reactive compatibilizer is a polyolefin reactive compatibilizer;

[0039] Other additives are ultraviolet absorber 2 hydroxy-4-n-octyloxybenzophenone;

[0040] Prepared by the following method:

[0041] 1. Ingredients: add homopolymerized PP, copolymerized PP and compatibilizer in the high-speed mixer in sequence according to the weight ratio of the formula, and pre-mix for 5 minu...

Embodiment 3

[0045] A high-performance polypropylene composite material consisting of the following raw materials in weight percent:

[0046]

[0047]

[0048] The above-mentioned homopolymer PP component is homopolypropylene, and its characteristic flexural modulus is 1700MPa;

[0049] The above-mentioned copolymerized PP component is copolymerized polypropylene, and its characteristic notched impact is 45KJ / m2;

[0050] The surface of the above-mentioned alkali-free glass fiber is treated with a silane coupling agent, and the diameter of the single filament is 9 microns;

[0051] The above-mentioned reactive compatibilizer is a polyolefin reactive compatibilizer;

[0052] Other additives are ultraviolet absorber 2 hydroxy-4-n-octyloxybenzophenone;

[0053] Prepared by the following method:

[0054] 1. Ingredients: add homopolymerized PP, copolymerized PP and compatibilizer in the high-speed mixer in sequence according to the weight ratio of the formula, and pre-mix for 5 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com