Improved he staining method

A dyeing method and hematoxylin technology, applied in the preparation of test samples, etc., can solve the problems of no further discussion on the influence of dyeing, inconsistent heating temperature, and increase dyeing quality, etc., to facilitate the control of dyeing quality, consistent temperature conditions, and dyeing. The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: the influence of different temperatures on HE dyeing effect

[0077] According to the above method 2 (the total process time is 18.5 minutes), 14 groups of experiments were carried out, and the temperature of the water bath in each group of experiments was set at 30°C, 35°C, 37°C, 40°C, 41°C, 42°C, 43°C, 44°C, 45°C, 46°C, 47°C, 48°C, 49°C and 50°C, the electromagnetic stirring speed was fixed at 1000rpm. The results are shown in Table 1 below.

[0078] Table 1: Effect of temperature on dyeing effect

[0079]

[0080]

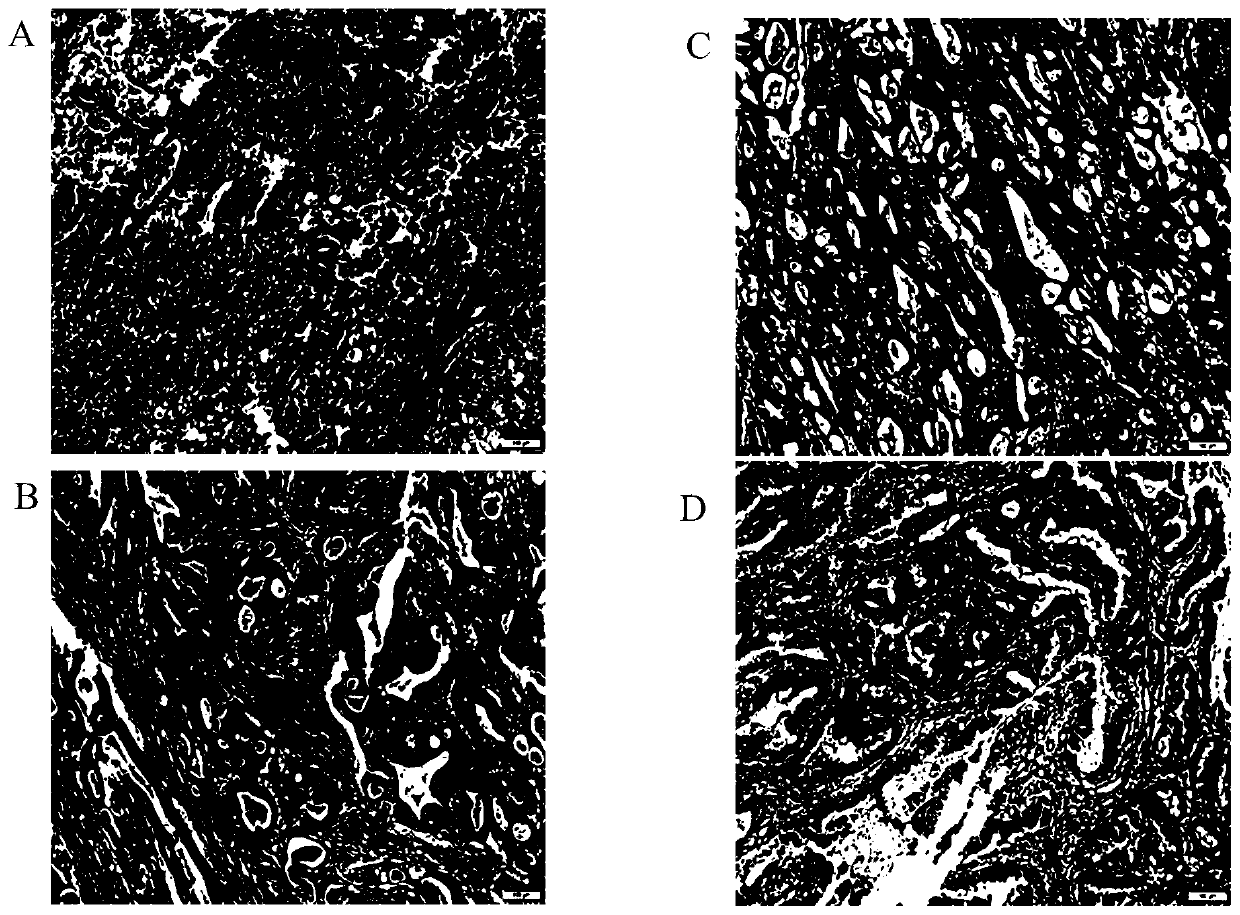

[0081] It can be seen from the above table that at the same rotating speed (1000rpm), the increase of temperature has no obvious effect on the chip falling. further reference figure 1 , it can be seen that when the temperature is lower than 41°C, the coloring of hematoxylin is lighter (B), and when the temperature is lower than 37°C (A), there is a phenomenon of blurred vision under the high power lens, which is because the dewaxing...

Embodiment 2

[0082] Embodiment 2: the influence of different temperatures on HE dyeing effect

[0083] According to the above method 1 (the total process time is 25.5 minutes), 14 groups of experiments were carried out, and the temperature of the water bath in each group of experiments was set at 30°C, 35°C, 37°C, 40°C, 41°C, 42°C, 43°C, 44°C, 45°C, 46°C, 47°C, 48°C, 49°C and 50°C, the electromagnetic stirring speed was fixed at 1000rpm. The results are shown in Table 2 below.

[0084] Table 2: Effect of temperature on dyeing effect

[0085]

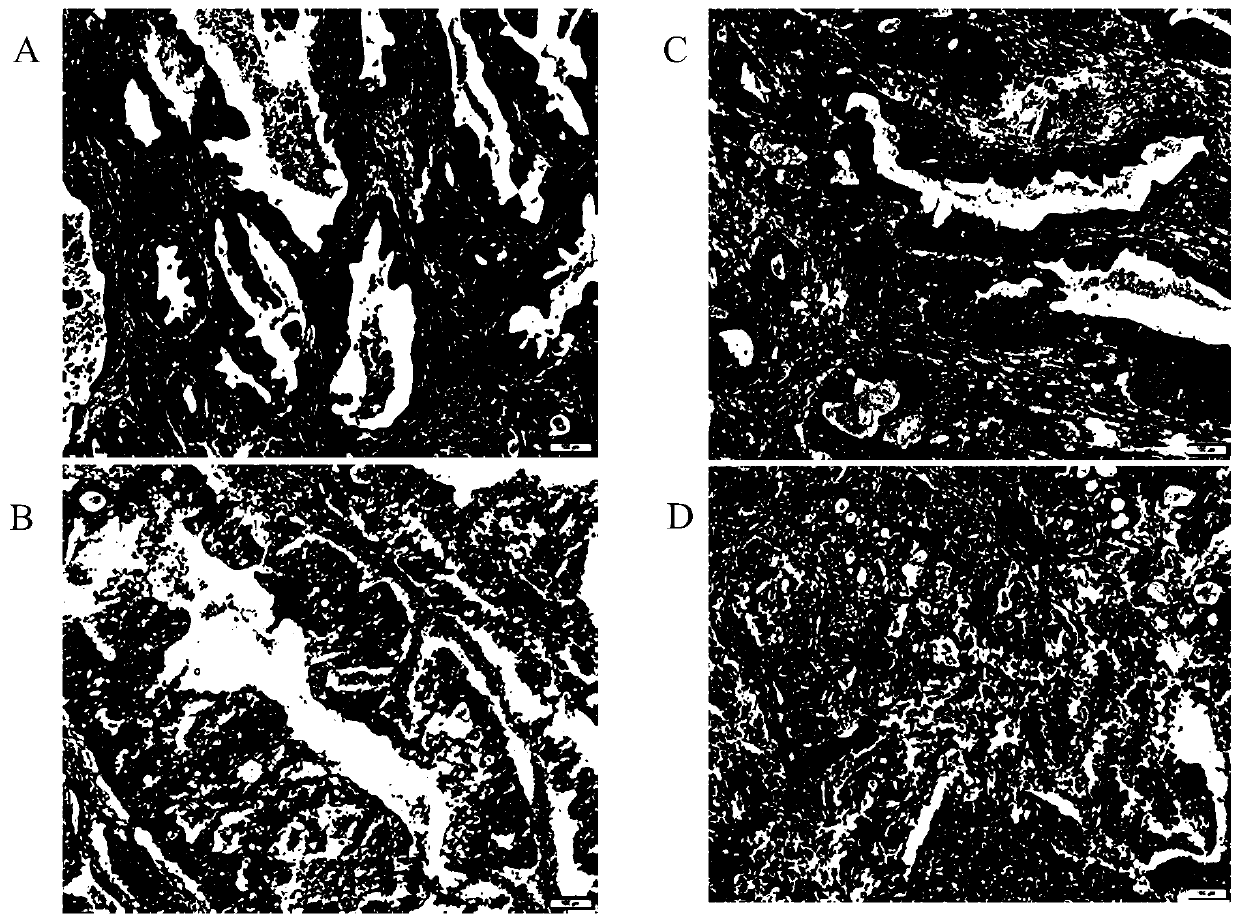

[0086] It can be seen from the above table that the dehydration and clearing steps after eosin dyeing are carried out under heating and stirring conditions to obtain similar effects as in Example 1. That is to say, at the same rotational speed (1000rpm), the increase of temperature has no obvious effect on the falling of slices; when it is lower than 41°C, the hematoxylin coloring is lighter, and when it is lower than 37°C, there is blurred visi...

Embodiment 3

[0087] Embodiment 3: the influence of different rotating speeds on HE dyeing effect

[0088] Five sets of experiments were carried out according to the above-mentioned method 2 (the total process time was 18.5 minutes), in which the temperature of the water bath was fixed at 42°C, and the electromagnetic stirring speed was set at 800rpm, 900rpm, 1000rpm, 1100rpm, and 1200rpm in each set of experiments. The results are shown in Table 3 below.

[0089] Table 3 The influence of rotating speed on the dyeing effect

[0090]

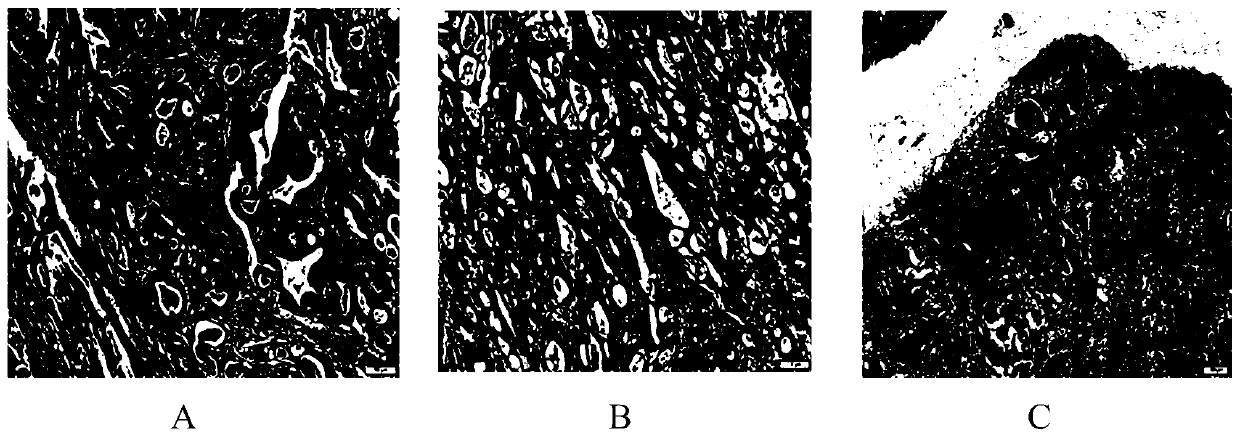

[0091] At the same temperature, the increase of rotational speed has no obvious effect on chip drop. combine figure 2 , it can be seen that when it is lower than 900rpm (A), the coloring of hematoxylin is lighter, and when it is higher than 1100rpm (C), the coloring of hematoxylin is darker. At 42°C, the preferred rotation speed is 900-1100rpm (B), with moderate coloring.

[0092] Exhaustion of the experiment according to Method 1 with an aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com