Forming method of stuffed food

A food forming and stuffing technology, applied in food science, dough processing, baking, etc., can solve the problems of high equipment cost, complex transmission equipment, complex transmission structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A method for forming stuffed food comprises the following steps:

[0079]The same cam drive structure simultaneously drives the two closing module assemblies 200 connected to it to move away from and approach each other, so as to realize the pressing and edge sealing of the stuffed food; and the cam driving structure drives each closing module assembly 200 to realize The kneading action of the outer surface of the stuffed food is to squeeze and knead the outer surface of the stuffed food.

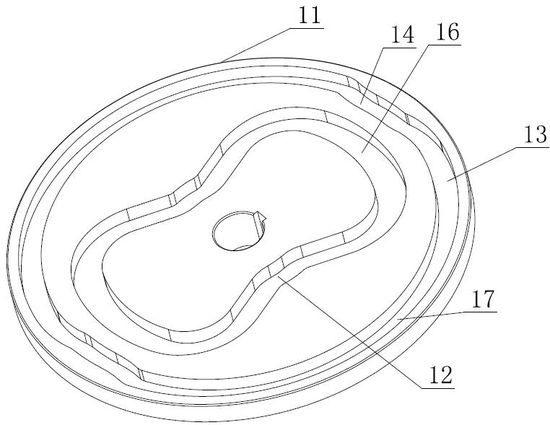

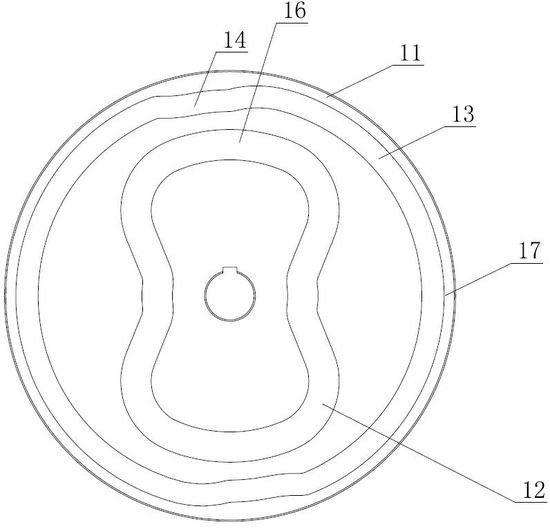

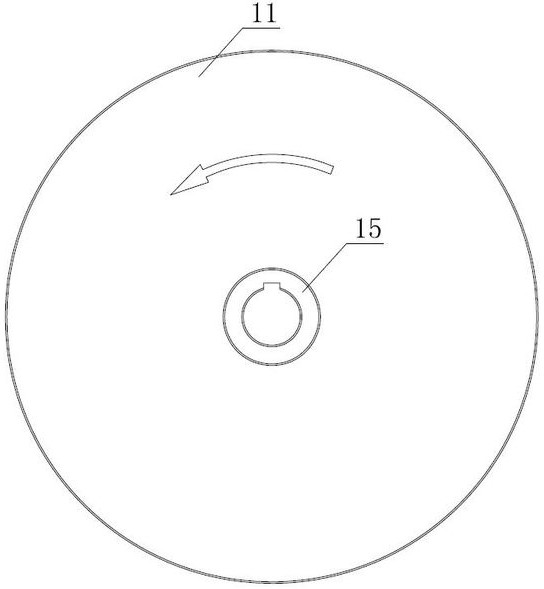

[0080] Further, the inner ring 12 of the double-slot cam disc 11 has a first driven bearing 32 connected to the two combined module assemblies 200, so when the double-slot cam turntable rotates, it is driven by the shape of the hourglass-shaped inner ring 12, and the two The combined module assembly 200 will move away from and close to each other, so as to realize the dough pressing effect on the stuffed food; there are two second driven bearings 37 in the outer ring 13 of the double...

Embodiment 2

[0082] The driving mechanism drives the double-groove cam disc 11 to rotate, and drives a pair of first driven bearings 32 and a pair of second driven bearings 37 located in the inner ring 12 and outer ring 13 to move along the paths in the grooves respectively. The two module mounting plates 31 connected to the two symmetrically arranged first driven bearings 32 in the inner ring 12 move toward and away from each other along the path of the inner ring 12, thereby realizing the relative arrangement of the combined module assembly 200 to the filling food. The edges of the dough are pressed and sealed; the two symmetrically arranged second driven bearings 37 in the outer ring 13 are connected with the grooved push blocks 38, which move towards and away from each other along the path of the outer ring 13, thereby respectively driving The outer push plate 315 and the inner push plate 314 move in opposite directions at the same time, and the outer push plate 315 and the inner push p...

Embodiment 3

[0084] A method for forming stuffed food comprises the following steps:

[0085] The same cam drive structure simultaneously drives the two closing module assemblies 200 connected to it to move away from and approach each other, so as to realize the pressing and edge sealing of the stuffed food; and the cam driving structure drives each closing module assembly 200 to realize The kneading action of the outer surface of the stuffed food is to squeeze and knead the outer surface of the stuffed food.

[0086] Further, the inner ring 12 of the double-slot cam disc 11 has a first driven bearing 32 connected to the two combined module assemblies 200, so when the double-slot cam turntable rotates, it is driven by the shape of the hourglass-shaped inner ring 12, and the two The combined module assembly 200 will move away from and close to each other, so as to realize the dough pressing effect on the stuffed food; there are two second driven bearings 37 in the outer ring 13 of the doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com