Controllable degradable biohydraulic membrane and its production method and application

A production method and technology of hydrogel film, applied in medical science, prosthesis, etc., can solve the problems of inconvenient transportation and use, damage to tissues and organs in the body, inaccurate analysis and research, etc., and achieve accurate and accurate pathological research and therapy research. Conducive to the effect of controllable self-organization molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary, and is not intended to limit the scope of the present invention and its application.

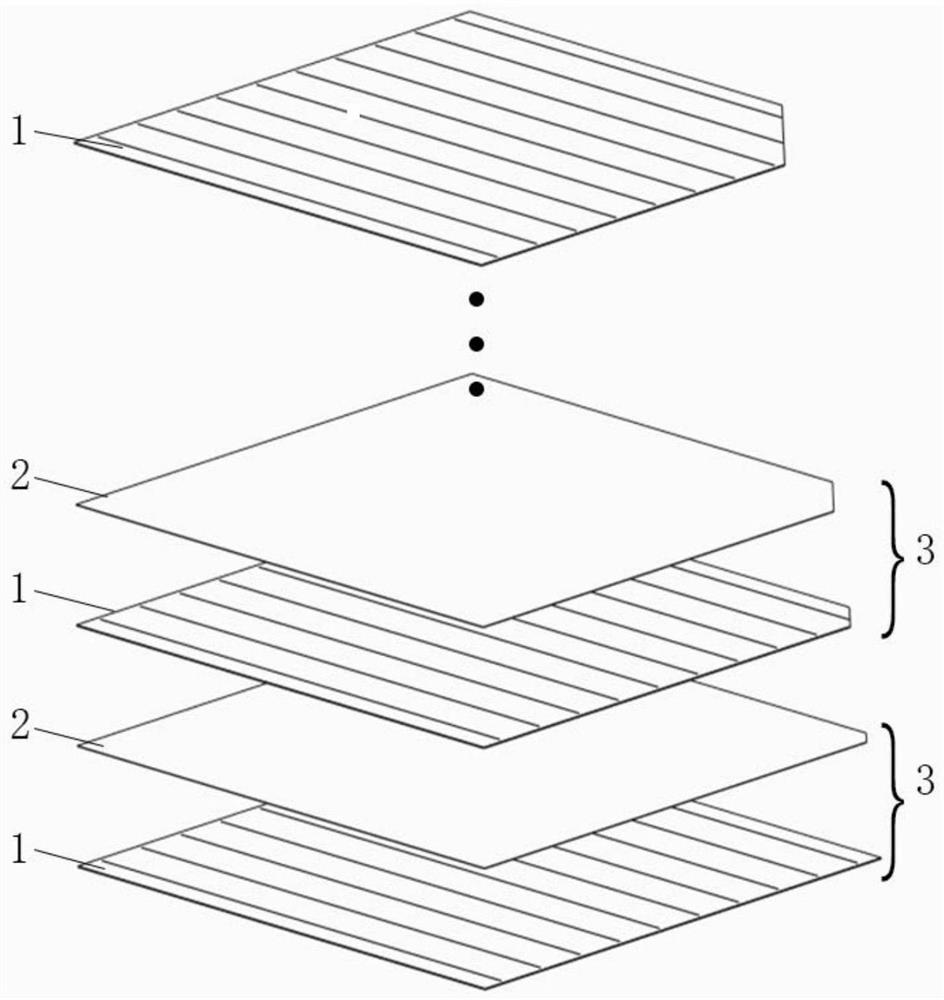

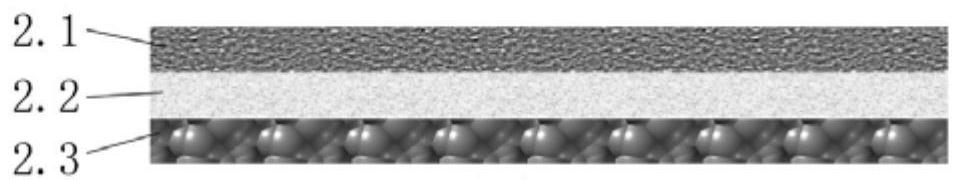

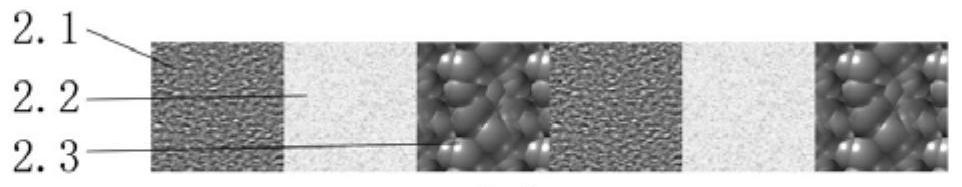

[0034]Refer tofigure 1 withFigure 2c In one embodiment, a controllable degradable biological hydrogel film includes: at least one layer of hydrogel film 2 between two layers of dielectric film 1, a layer of dielectric film 1 and a layer of hydrogel The membrane 2 constitutes a unit structure 3; at least two layers of dielectric membrane 1 that can be detached from the hydrogel membrane 2 are used to encapsulate and protect the hydrogel membrane 2; wherein the hydrogel membrane 2 is a variety of Biocompatibility and biodegradability of medical hydrogel materials are formed by layering and / or cross-arrangement and / or uniform mixing, so as to achieve the gradual degradation of different materials and produce different microstructures to induce tissue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com