Method for controllably preparing novel ZnO/Ag recycled surface enhanced Raman active photocatalyst material

A technology of surface-enhanced Raman and photocatalytic materials, applied in the field of materials, can solve problems affecting the visible light catalytic activity of products, difficult to control product shape and size, single product function, etc., achieve high visible light catalytic activity, reduce experimental costs, The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

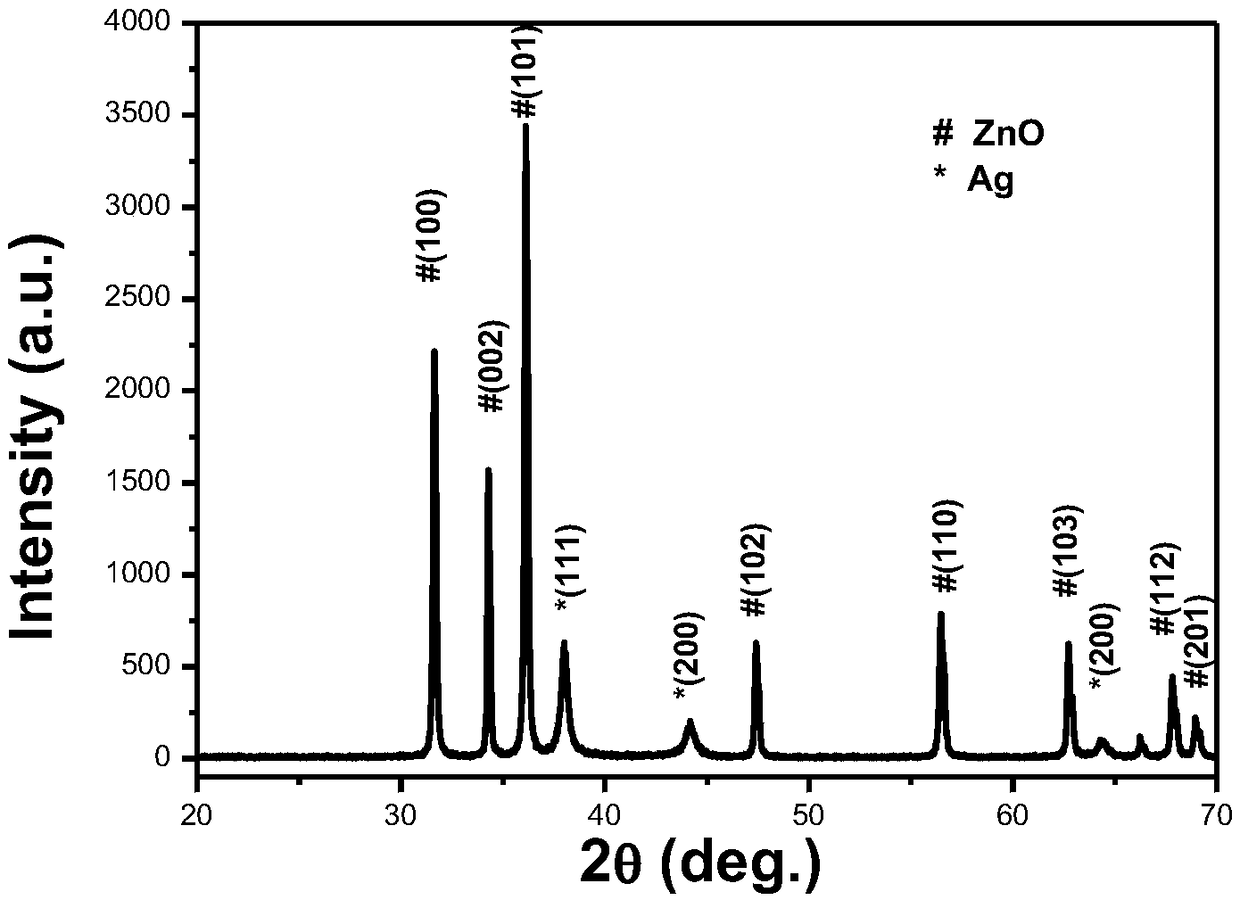

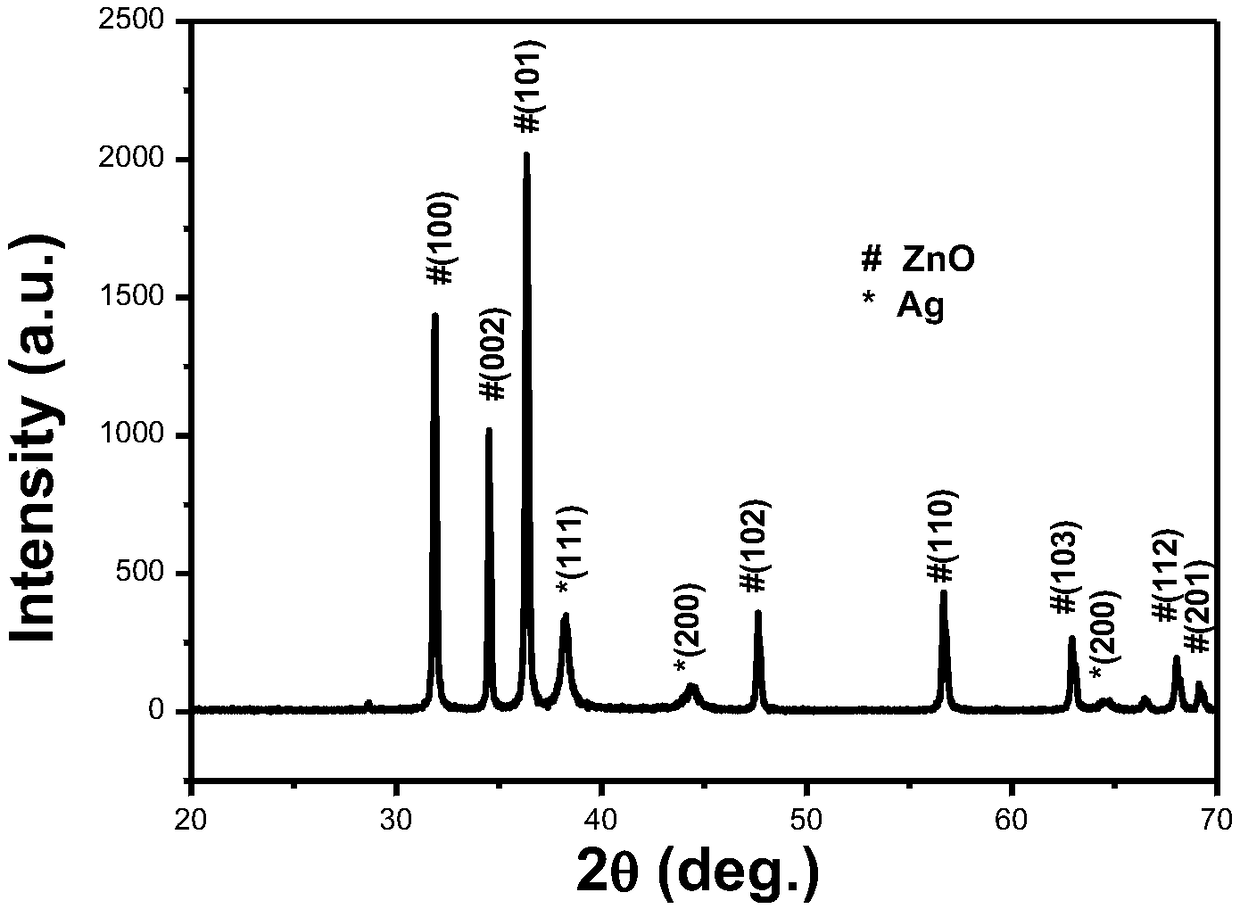

Image

Examples

Embodiment 1

[0027] Zn(NO 3 ) 2 ·6H 2 O(10mmol) and NH 4 F (0.1mol) was dissolved in 80mL water and stirred for 15min, NaOH (15mmol) was added, and after stirring for 15min, the temperature was raised to 120°C and reacted for 10h, then naturally cooled to room temperature, filtered and precipitated, washed with deionized water and ethanol, and then Vacuum drying at 60°C for 6h gave ZnOHF (1.00g).

Embodiment 2

[0029] ZnCl 2 (10mmol) with NH 4 Dissolve F (0.1mol) in 50mL water and stir for 20min, add KOH (12mmol), continue stirring for 20min, heat up to 110°C and react for 12h, then naturally cool to room temperature, filter, wash with deionized water and ethanol for precipitation, and Vacuum drying at 70°C for 10 h gave ZnOHF (0.98 g).

Embodiment 3

[0031] ZnSO 4 (10mmol) with NH 4 F (0.1mol) was dissolved in 70mL of water and stirred for 18min, then LiOH (12mmol) was added, and after stirring for 18min, the temperature was raised to 130°C for 16h, and then naturally cooled to room temperature, filtered and washed with deionized water and ethanol. Vacuum drying at 70°C for 10 h gave ZnOHF (0.96 g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com